Abstract

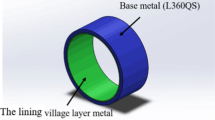

The effects of manual tungsten inert gas welding (GTAW) and automatic GTAW on the microstructure and mechanical properties of L360QS/N08825 composite pipe welded joints were investigated. The welded joints obtained by the two welding methods were subjected to tensile, bending, hardness and low-temperature impact test. The fracture morphology, chemical composition and microstructure were observed and analyzed by scanning electron microscope and optical microscope, respectively. The results showed that welded joints with good microstructure and mechanical properties can be achieved by both the two welding methods. Compared with manual GTAW, the microstructure of automatic GTAW welded joint is smaller and more uniform and the mechanical properties are improved. The two welding methods can play their respective advantages in different working environments and welding positions.

Similar content being viewed by others

References

Zhang L J, Pei Q, Zhang J X, Bi Z Y, and Li P C, Mater Design64 (2014) 462.

Jiang F, and Zhao K, Sun J. Int J Press Vessels Pip80 (2003) 129.

Kacar R, and Acarer M. J Mater Process Technol152 (2004) 91.

Qian X, and Wang Y, Richard Liew J R, Zhang M H, Eng Struct92 (2015) 84.

Mortezaie A, and Shamanian M. Int J Press Vessels Pip116 (2014) 37.

Jang C, Lee J, Kim J S, and Jin T E, Int J Press Vessels Pip85 (2008) 635.

Strubbia R, Hereñú S, Giertler A, Alvarez-Armas I, and Krupp U, Int J Fatigue65 (2014) 58.

Yang J, Wang G Z, Xuan F Z, Tu S T, and Lin C J, Mater Design55 (2014) 542.

Wang H T, Wang G Z, Xuan F Z, and Tu S T, Mater Design44 (2013) 179.

Rajani H R Z, and Mousavi S A A A. Mater Sci Eng A (Struct Mater Prop Microstruct Process) 556 (2012) 454.

Deng X, Lu F, Cui H, Tang X, and Li Z, Mater Sci Eng A651 (2016) 1018.

Hosseini H S, Alishahi M, and Shamanian M. Mater Lett67 (2012) 259.

Shakil M, Tariq N H, Ahmad M, Choudhary M A, Akhter J I, and Babu S S, Mater Design55 (2014) 263.

Xie M X, Zhang L J, Zhang G F, Zhang J X, Bi Z Y, and Li P C, Mater Design87 (2015) S0264127515302707.

Falat L, Svoboda M, Anna Vyrostková, Petryshynets I, and Sopko M, Mater Charact72 (2012)15.

Cao J, Gong Y, Zhu K, Yang ZG, Luo X M, and Gu F M Mater Design32 (2011) 2763.

Shanmugam S, Misra R D K, Hartmann J, and Jansto S G, Mater Sci Eng A441 (2006) 215.

Pandey C, Mohan Mahapatra M, Kumar P, Thakre J G, and Saini N, J Mater Process Technol263 (2019) 241.

Chaurasia P K, Pandey C, Giri A, Saini N, and Mahapatra M M, Arch Metall Mater63 (2018) 1019.

Pandey C, Saini N, Mahapatra M M, and Kumar P, Eng Fail Anal71 (2017) 131.

Pandey C, Mahapatra M M, Kumar P, Saini N, J Eng Mater Technol139 (2017) 031004.

Zongyue B I, Yang J, Jing N, Zhang J, Acta Metall Sin49 (2013) 576.

Yadav R, Pandey C, Mahapatra M M, and Mulik R S Trans Indian Institute Met70 (2017) 1805.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, B., Lan, H. & Lei, B. Effect of Welding Method on Microstructure and Mechanical Properties of L360QS/N08825 Composite Pipe Welded Joint. Trans Indian Inst Met 73, 629–643 (2020). https://doi.org/10.1007/s12666-020-01865-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01865-4