Abstract

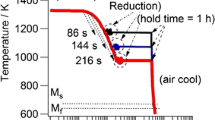

0.3%C–CrMoV steel were processed through electric arc furnace melting followed by electro slag refining. 2800 mm diameter class of rolled rings and 8 mm thick plates required for fabrication of solid rocket booster motorcase were realized. Tensile and fracture toughness properties were evaluated as a part of characterization of the steel. Low fracture toughness in initial melts was investigated using optical and scanning electron microscopy. Modifications in methods of alloying additions/processing were suggested and incorporated to achieve the desired mechanical properties in industrial scale melts. Process was also fine-tuned by incorporating additional thermomechanical working and heat treatment cycles to achieve the required mechanical properties. Hardening cycle of 925 °C for 1 h followed by oil quenching and tempering cycle of 505 °C for 2 h followed by oil quenching was found to result in optimum combination of mechanical properties. Repeatability in processing and consistency in achieving the mechanical properties of the steel at industrial scale was demonstrated by processing 24 melts of 6 tons each into large size rings and plates.

Similar content being viewed by others

References

Sreekumar K, Murthy M S P, Natarajan A, Sinha PP, and Nagarajan K V, Trans Indian Inst Met 35 (1982) 349.

Padki G M, Balasubramanian M S N, Gupta K M, Rao P K, and Climax Molybdenum Co., Ironmak Steelmak 10 (1983) 180.

Chatterjee M, Balasubramanian M S N, Gupta K M, Rao P K, Ironmak Steelmak 17 (1990) 38.

Maity S K, Ballal N B, and Kawalla R, Iron Steel Inst Jpn Int 46 (2006) 1361.

Maity S K, Ballal N B, Kawalla R, and Goldhahn G, Iron Steel Inst Jpn Int 49 (2008) 902.

Suresh M R, Ph D thesis, Department of Metallurgical Engineering and Material Science, IIT Bombay, India (2002).

Bandyopadhyay T R, Krishna Rao P, and Prabhu N, Ironmak Steelmak 33 (2006) 331.

Bandyopadhyay T R, Ultrahigh Strength Steel Development Using Electroslag Refining with Inoculation, Ph D thesis, Department of Metallurgical Engineering and Material Science, IIT Bombay, India (2006).

Vaish A K, Iyer G V R, De, P K, Lakra B K, and Chakrabarti A K, Ramachandra Rao P, J Metall Mater Sci 42-1 (2000) 11.

Patent: Method of anti-flake treatment of rolling products out of steel alloy. http://russianpatents.com/patent/225/2258747.html. Accessed Jun 2016.

Suresh M R, Trans Indian Inst Met 64 (2011) 483.

Suresh M R, Samajdar I, Ingle A, Ballal N B, Rao P K, Sinha P P, Ironmak Steelmak 30 (2003) 379.

Gladman T, The Physical Metallurgy of Micro alloyed Steels, The Institute of Materials, The University Press, London (1997), p 28.

Honeycombe R, and Bhadeshia H K D H, Steel: Microstructure and Properties, 2nd edn, Gray Publishing, Tunbridge Wells, Kent (1995), p 13.

Pickering F B, and Gladman T., ISI Special Report (1961), p 81.

Mishra S K, Das S, and Ranganathan S, Mater Sci Eng A 323 (2002) 285.

Alsagabi S, Shrestha T, and Indrajit C, J Nucl Mater 453 (2014) 151.

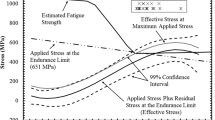

Beena A P, Sunderesan M K, Nageswara Rao B, Int J Press Vessel Pip 62 (1995) 313.

Monograph on Solid rocket motor metal cases, NASA SP-8025. https://ntrs.nasa.gov/search.jsp?R=19700020430. Accessed Jun 2016.

Acknowledgements

We are thankful to Dr. P. P. Sinha and Dr. M.R. Suresh for technical guidance and support during this study. We are also grateful to colleagues of IFF; MCD & HWMD/MMG for fabrication and testing facility support. Director, VSSC is acknowledged for his kind permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramkumar, P., Anil Kumar, V., Gupta, R.K. et al. Melting and Thermomechanical Processing of High Strength 0.3%C–CrMoV (ESR) Steel. Trans Indian Inst Met 71, 1475–1485 (2018). https://doi.org/10.1007/s12666-018-1283-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1283-2