Abstract

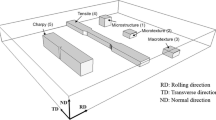

A novel 2000 MPa grade ultra-high-strength steel AIR0509 with high fracture toughness and low cost has recently been developed. The effects of solid-solution temperature on the microstructure and mechanical properties of this steel were investigated. The increase in solid-solution temperature first increased and then decreased the values of ultimate strength (UTS) and Charpy U-notch (CUN) energy. The increase in the UTS and CUN values was caused by the dissolution of the primary carbides M6C and MC, while the decrease in both strength and toughness was due to the increase in the prior austenite grain size. Samples that were solid-solution treated at 1000 °C exhibited an optimal combination of strength and toughness with a UTS of 2020 MPa, yield strength of 1780 MPa, and CUN energy of 68 J, as well as a correlative fracture toughness KIC value of about 105 MPa m1/2.

Similar content being viewed by others

References

H.M. Flower, in: High Performance Materials in Aerospace, Springer, Dordrecht, The Netherlands, 1995, pp. 227–245.

E.W. Lee, C.E. Neu, J. Kozol, JOM 42 (1990) 11–15.

R. Ayer, P.M. Machmeier, Metall. Trans. A 24 (1993) 1943–1955.

H.J. Jou, Lower-cost, ultra-high-strength, high-toughness steel, US, 9051635B2, 2015.

R.M. Hemphill, D.E. Wert, P.M. Novotny, M.L. Schmidt, High strength, high fracture toughness alloy, US, 5268044, 1993.

R. Veerababu, K.S. Prasad, R. Balamuralikrishnan, S. Karthikeyan, Mater. Charact. 144 (2018) 191–204.

Y.H. Gao, S.Z. Liu, X.B. Hu, Q.Q. Ren, Y. Li, V.P. Dravid, C.X. Wang, Mater. Sci. Eng. A 759 (2019) 298–302.

R. Ayer, P.M. Machmeier, Metall. Mater. Trans. A 27 (1996) 2510–2517.

R. Ayer, P. Machmeier, Metall. Mater. Trans. A 29 (1998) 903–905.

L. Morsdorf, O. Jeannin, D. Barbier, M. Mitsuhara, D. Raabe, C.C. Tasan, Acta Mater. 121 (2016) 202–214.

G.R. Speich, D.S. Dabkowski, L.F. Porter, Metall. Trans. 4 (1973) 303–315.

W.M. Garrison Jr, M. Rhoads, Trans. Indian Inst. Met. 49 (1996) 151–162.

I. Souki, D. Delagnes, P. Lours, Procedia Eng. 10 (2011) 631–637.

Z.B. Jiao, J.H. Luan, M.K. Miller, Y.W. Chung, C.T. Liu, Mater. Today 20 (2017) 142–154.

H. Güler, R. Ertan, R. Özcan, Mater. Tehnol. 48 (2014) 971–976.

J. Adamczyk, E. Kalinowska-Ozgowicz, W. Ozgowicz, R. Wusatowski, J. Mater. Process. Technol. 53 (1995) 23–32.

H. Babaei, A. Shafyei, K. Amini, Mechanics 22 (2016) 576–580.

H. Hou, L. Qi, Y.H. Zhao, Mater. Sci. Eng. A 587 (2013) 209–212.

W. Rong, H.O. Andrén, H. Wisell, G.L. Dunlop, Acta Metall. Mater. 40 (1992) 1727–1738.

Y.P. Zhang, D.P. Zhan, X.W. Qi, Z.H. Jiang, Mater. Sci. Eng. A 730 (2018) 41–49.

A. Mondiere, V. Déneux, N. Binot, D. Delagnes, Mater. Charact. 140 (2018) 103–112.

B. Sundman, B. Jansson, J.O. Andersson, Calphad 9 (1985) 153–190.

M.R. Ghomashchi, Acta Mater. 46 (1998) 5207–5220.

K.C. Hwang, S. Lee, H.C. Lee, Mater. Sci. Eng. A 254 (1998) 296–304.

H.F. Fischmeister, R. Riedl, S. Karagöz, Metall. Trans. A 20 (1989) 2133–2148.

S.C. Kennett, G. Krauss, K.O. Findley, Scripta Mater. 107 (2015) 123–126.

C. Du, J.P.M. Hoefnagels, R. Vaes, M.G.D. Geers, Scripta Mater. 120 (2016) 37–40.

D.J. Dyson, S.R. Keown, D. Raynor, J.A. Whiteman, Acta Metall. 14 (1966) 867–875.

D.J. Bacon, U.F. Kocks, R.O. Scattergood, Philo. Mag. A 28 (1973) 1241–1263.

Z.B. Jiao, J.H. Luan, Z.W. Zhang, M.K. Miller, C.T. Liu, Scripta Mater. 87 (2014) 45–48.

L. Sun, T.H. Simm, T.L. Martin, S. McAdam, D.R. Galvin, K.M. Perkins, P.A.J. Bagot, M. Moody, S.W. Ooi, P. Hill, Acta Mater. 149 (2018) 285–301.

D.S. McDarmaid, Met. Technol. 7 (1980) 372–377.

G.Y. Lai, W.E. Wood, R.A. Clark, V.F. Zackay, E.R. Parker, Metall. Trans. 5 (1974) 1663–1670.

R.O. Ritchie, B. Francis, W.L. Server, Metall. Trans. A 7 (1976) 831–838.

C.N. Sastry, W.E. Wood, Materi. Sci. Eng. 45 (1980) 277–280.

H.R. Yang, K.B. Lee, H. Kwon, Metall. Mater. Trans. A 32 (2001) 2393–2396.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Cx., Gao, Yh., Li, Y. et al. Effects of solid-solution temperature on microstructure and mechanical properties of a novel 2000 MPa grade ultra-high-strength steel. J. Iron Steel Res. Int. 27, 710–718 (2020). https://doi.org/10.1007/s42243-020-00367-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00367-3