Abstract

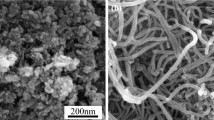

Multiwalled carbon nanotubes (MWCNTs) were modified noncovalently with cetyltrimethylammonium bromide. The Nb/Nb5Si3 in situ composite material that was strengthened with MWCNTs was prepared by SPS. The effect of MWCNT content on the microstructure and properties of Nb/Nb5Si3 in situ composites was investigated. The results showed that the composites consisted of Nb, α-Nb5Si3 and β-Nb5Si3 phases. With the addition of over 2 wt% MWCNT, a new Nb4C3 phase was formed in the composites. The properties of the Nb/Nb5Si3 in situ composites were affected by MWCNT addition. The relative density, Vickers hardness and fracture toughness increased with increasing MWCNT addition. When the MWCNT addition was 2 wt%, the relative density and Vickers hardness reached a maximum and increased by ~ 1.4% and ~ 18%, respectively (relative to 0 wt% MWCNT addition). When the MWCNT content exceeded 2 wt%, the relative density and the Vickers hardness decreased. However, the fracture toughness of the Nb/Nb5Si3 composites with 3 wt% MWCNTs reached a maximum (an increase of ~ 68% relative to 0 wt% MWCNT addition). Scanning electron micrographs of the fractography showed brittle cleavage and partial intercrystalline composite fracture. The composite toughening mechanisms arose mainly because of MWCNT removal and bridging.

Similar content being viewed by others

References

Bewlay B P, Jackson M R, Subramanian P R, and Zhao J C, Metall Mater Trans A 34 (2003) 2043.

Tang Y, and Guo X P, Scr Mater 116 (2016) 16.

Wang F, Luo L, Xu Y, Meng X, Wang L, Han B, Su Y, Guo J, and Fu H, Intermetallics 88 (2017) 6.

Sun Z P, Guo J M, and Zhang C, Rare Metal Mater Eng 45 (2016) 1678.

Li Z, and Tsakiropoulos P, Intermetallics 26 (2012) 18.

Su L, Jia L, Yuan S, Zhou L, Zhang H, and Zhang H, Mater Sci Technol 31 (2014) 220.

Maji P, Mitra R, Ray K K, Intermetallics 85 (2017) 34.

Zhang S, and Guo X, Intermetallics 64 (2015) 51.

Grammenos I, and Tsakiropoulos P, Intermetallics 19 (2011) 1612.

Xiong B W, Cai C C, and Wang Z J, J Alloys Compd 583 (2014) 574.

Guo Y, Jia L, Kong B, Zhang H, and Zhang H, Intermetallics 92 (2018) 1.

Sha J, Hisatoshi H, Tatsuo T, Akira K, Hidetoshi U, and Shuji H, Mater Trans JIM 41 (2000) 1125.

Kim W Y, Yeo I D, Ra T Y, Cho G S, and Kim M S, J Alloys Compd 364 (2004) 186.

Kang Y, Qu S, Song J, Huang Q, and Han Y, Mater Sci Eng A 534 (2012) 323.

Zhang S, and Guo X, Intermetallics 57 (2015) 83.

Thandorn T, and Tsakiropoulos P, Intermetallics 18 (2010) 1033.

Li Z F, and Tsakiropoulos P, Intermetallics 18 (2010) 1072.

Tiwary C S, Kashyap S, and Chattopadhyay K, Mater Sci Eng A 560 (2013) 200.

Vellios N, and Tsakiropoulos P, Intermetallics 18 (2010) 1729.

Geng J, Tsakiropoulos P, Shao G, Intermetallics 15 (2007) 69.

Kim W Y, Tanaka H, Kasama A, and Hanada S, Intermetallics 9 (2001) 827

Kim W Y, Tanaka H, and Hanada S, Intermetallics 10 (2002) 625.

Sha J, Hirai H, Ueno H, Tabaru T, Kitahara A, and Hanada S, Metal Mater Trans A 34 (2003) 2861

Esparza N, Rangel V, Gutierrez A, Arellano B, and Varma S K, Mater High Temp 33 (2016) 105.

Jia L N, Weng J F, Li Z, Hong Z, Su L F, and Zhang H, Mater Sci Eng A 623 (2015) 32.

Li Z, and Tsakiropoulos P, J Alloys Compd 550 (2013) 553.

Kashyap S, Tiwary C S, and Chattopadhyay K, Intermetallics 19 (2011) 1943.

Knittel S, Mathieu S, and Vilasi M, Intermetallics 47 (2014) 36.

Sun Z P, Guo X P, Tian X D, and Zhou L, Intermetallics 54 (2014) 143.

Jagannatham M, Sankaran S, and Haridoss P, Mater Sci Eng A 638 (2015) 197.

Feng X, Sui J H, Cai W, and Liu A L, Scr Mater 64 (2011) 824.

Feng X, Sui J H, and Cai W, J Compos Mater 45 (2011) 1553.

Lee J, Hwang J, Lee D, Ryu H J, and Hong S H, J Alloys Compd 617 (2014) 505.

Kondoh K, Threrujirapapong T, Imai H, Umeda J, and Fugetsu B, Compos Sci Technol 69 (2009) 1077,

Ye D L, and Hu J H, Handbook of Inorganic Thermodynamics, Metallurgical Industry Press, Beijing (2002).

Sekido N, Wei F G, Kimura Y, Miura S, and Mishima Y, Philos Mag Lett 86 (2006) 89.

Khor K A, Cheng K H, Yu L G, and Boey F, Mater Sci Eng A 347 (2003) 300.

Chen Z, and Yan Y W, J Wuhan Univ Technol (Mater Sci Ed) 22 (2007) 299.

Wang X L, Wang G F, and Zhang K F, Mater Sci Eng A 527 (2010) 3253.

Ameri S, Sadeghian Z, and Kazeminezhad I, Intermetallics 76 (2016) 41.

Ma C L, Li J G, Tan Y, Tanaka R, and Hanada S, Mater Sci Eng A 384 (2004) 377.

Bakshi S R, Lahiri D, and Agarwal A, Int Mater Rev 55 (2010) 41.

Acknowledgements

In this paper, the research was sponsored by the National Natural Science Foundation of China (Project No. 51271091) and the Nature Science Foundation of Jiangxi Province (Project No. 20161BAB206107) and the technology project of Jiangxi Province Education Department (Project No. GJJ12420).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Long, W., Zeng, X. & Jia, H. Microstructure and Properties of Nb/Nb5Si3 Composites Strengthened with Multiwalled Carbon Nanotubes by SPS. Trans Indian Inst Met 72, 983–991 (2019). https://doi.org/10.1007/s12666-018-01559-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-01559-y