Abstract

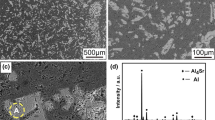

Scandium addition in Al–Si alloys can reduce grain size and modify the structure from flake-like to fibrous. To use this Sc-modified Al–Si alloy in practical applications, there are many factors that need to be studied, including porosity formation. However, there is limited available information with regard to the effect of Sc on porosity formation. This research used the Tatur test mold to investigate the effect of strontium and scandium on porosity formation in Al–6Si–0.3 Mg alloys. Sc addition promoted the fibrous structure of eutectic silicon and reduced grain size. Sc addition also resulted in smaller and more dispersed porosity across the samples compared to that of unmodified samples. Once the Sc addition reached 0.4 wt%, the τ phase (AlSi2Sc2) was clearly observed. It is believed that the τ phase promoted more oxidation during casting and eventually led to higher numbers of porosity in the casting.

Similar content being viewed by others

References

Sabatino M. D. and Arnberg L., Trans Ind Inst Met, 62(4–5) (2009) 321.

Ware T. N., Dahle A. K., Charles S., Couper M. J., Effect of Sr, Na, Ca & P on the castability of foundry alloy A356.2, ASM Materials Solutions 2002 Conference and Exposition, 2nd International Aluminum Casting Technology Symposium, Columbus, Ohio, USA, (2002) p. 159.

Gruzleski J. E., Bernard C. M., The Treatment of Liquid Aluminium-Silicon Alloys, American Foundrymen’s Society, Inc., USA (1990) p. 63.

Arbenz H., Lunkerneigung von Aluminium-Guslegierungen, Giesserei (1962) p. 105.

Dinnis C. M., Otte M. O., Dahle A. K., Taylor J. A., Metall. Mater. Trans. A, 35A (2004) 3531.

Tiedje N. S., Taylor J. A., Easton M. A., Metall. Mater. Trans. A, 43 (2012) 4846.

Toropova L. S., Eskin D. G., Kharakterova M. L., Dobatkina T.V., Advanced Aluminum Alloys Containing Scandium: Structure and Properties, Baikov Institute of Metallurgy, Moscow, Russia (1998) p. 133.

Prukkanon W., Srisukhumbovornchai N., Limmaneevichitr C., J. Alloys. Compd., 477 (2009) 454.

Prukkanon W., Srisukhumbowornchai N., Limmaneevichitr C., J. Alloys. Compd., 487 (2009) 453.

Patakham U., Kajornchaiyakul J., Limmaneevichitr C., J. Alloys. Compd., 542 (2012) 177.

Argo D. and Gruzleski J. E., AFS Trans., 96 (1988) 65.

Nogita K., McDonald S. D., Zindel J. W., Dahle A. K., Mater. Trans., 42 (2001) 1981.

Nogita K., Knuutinen A., McDonald S. D., Dahle A. K., J. Light. Met., 1 (2001) 219.

Dahle A., Nogita K., McDonald S., Zindel J., Hogan L., Metall. Mater. Trans. A, 32 (2001) 949.

Lu L., Nogita K., Mcdonald S. D., Dahle A. K., Eutectic solidification and its role in casting porosity formation, JOM, (2004) p. 52.

Lu L., Nogita K., Dahle A. K., Mater. Sci. Eng. A, 399 (2005) 244.

McDonald S. D., Nogita K., Dahle A. K., J. Alloys. Compd., 422 (2006) 184.

Pandee P., Gourlay C. M., Belyakov S. A., Ozaki R., Yasuda H., Limmaneevichitr C., Metall. Mater. Trans. A, 45A (2014) 4549.

Campbell J., Tiryakioğlu M., Mater. Sci. Tech., 26 (2010) 262.

Miresmaeili S. M., Campbell J., Shabestari S. G., Boutorabi S. M. A., Metall. Mater. Trans. A, 36A (2005) 2341.

Kim M., Hong Y., Cho H., Metals. Mater. Int. (2004) 10(6):513.

McDonald S. D., Dahle A. K., Taylor J. A., StJohn D. H., Metall. Mater. Trans. B, 35B (2004) 1097.

Moustafa M. A., J. Mater. Proc. Tech., 209 (2009) 605.

Acknowledgments

This work was financially supported by the National Research University Project of Thailand’s Office of the Higher Education Commission. We graciously acknowledge the Royal Thai Government Scholarship (Ministry of Science and Technology) for Mr. Kongkiat Puparattanapong for his Ph.D. study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puparattanapong, K., Limmaneevichitr, C. Effect of Scandium on Porosity formation in Al–6Si–0.3 Mg Alloys. Trans Indian Inst Met 69, 1587–1594 (2016). https://doi.org/10.1007/s12666-015-0732-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0732-4