Abstract

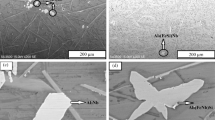

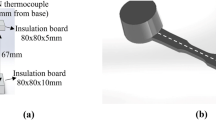

The presence and morphology of Fe-containing intermetallic phases affect the mechanical properties of aluminum alloys, especially in secondary Al–Si-based cast alloys. Although strontium (Sr) addition of 50 to 500 ppm is known to refine the needle-type eutectic silicon structure, the influence of Sr on the formation of Fe-intermetallic phases remains unclear. The present work investigates the combined additions of Sr and Mn to Al–9Si–0.6Fe–0.35Mg (All compositions are in wt pct except otherwise stated.) alloys on the formation of Fe-intermetallic phases at different solidification rates from ~ 1.5 to ~ 60 °C/s. Long and branched-type AlFeSi phase with size ranging from 50 to 120 µm are more common when solidified at the rate of 1.5 °C/s regardless of Sr and Mn additions. However, at the fast solidification rate of 60 °C/s, a 60 ppm Sr addition significantly reduced the average length of needle-shaped AlFeSi phase to less than 3 to 5 µm. Thermodynamic simulations have been performed using CALculation of PHAse Diagrams (CALPHAD) models to predict the formation of various phases and their possible interactions during solidification. The results indicated that the combination of a high solidification rate and about 60 ppm of Sr is beneficial to refining the δ-Al3FeSi2 phase in Al–Si–Mg alloys containing 0.6 pctFe. This unexpected finding of Fe-intermetallic refinement by low Sr addition (~60 ppm) provides an important guide in designing secondary alloys for sustainable casting applications.

Similar content being viewed by others

Data Availability

All data are available upon request. Please submit your request to the corresponding author.

References

A.A. Luo, A.K. Sachdev, and D. Apelian: J. Mater. Process. Technol., 2022, vol. 306, 117606.

T. Dursun and C. Soutis: Mater. Des., 2014, vol. 56, pp. 862–71.

F.C. Campbell: Aluminum, Elsevier Science, Oxford, 2006, pp. 15–92.

K.K. Sankaran and R.S. Mishra: Aluminum Alloys, Elsevier, Amsterdam, 2017, pp. 57–176.

I. Polmear, D. StJohn, J.-F. Nie, and Ma. Qian: Casting of Light Alloys, Butterworth-Heinemann, Boston, 2017, pp. 109–56.

T.E. Lipman and P. Maier: MRS Bull., 2022, vol. 46, pp. 1164–75.

D. Paraskevas, K. Kellens, W. Dewulf, and J.R. Duflou: J. Clean. Prod., 2015, vol. 105, pp. 357–70.

B. Cushman-Roisin and B.T. Cremonini: Materials, Elsevier, Amsterdam, 2021, pp. 1–16.

J. Fred Major: Aluminum and Aluminum Alloy Castings. ASM International, 2008, pp. 1059–84.

S. Van den Eynde, E. Bracquene, D. Diaz-Romero, I. Zaplana, B. Engelen, J.R. Duflou, and J.R. Peeters: Waste Manag., 2022, vol. 137, pp. 231–40.

G. Gaustad, E. Olivetti, and R. Kirchain: Resour. Conserv. Recy., 2012, vol. 58, pp. 79–87.

D. Raabe, D. Ponge, P.J. Uggowitzer, M. Roscher, M. Paolantonio, C.L. Liu, H. Antrekowitsch, E. Kozeschnik, D. Seidmann, B. Gault, F. De Geuser, A. Deschamps, C. Hutchinson, C.H. Liu, Z.M. Li, P. Prangnell, J. Robson, P. Shanthraj, S. Vakili, C. Sinclair, L. Bourgeois, and S. Pogatscher: Prog. Mater. Sci., 2022, vol. 128, 100947.

L. Wang, M. Makhlouf, and D. Apelian: Int. Mater. Rev., 1995, vol. 40, pp. 221–38.

L.F. Zhang, J.W. Gao, L.N.W. Damoah, and D.G. Robertson: Min. Proc. Ext. Met. Rev., 2012, vol. 33, pp. 99–157.

J.A. Taylor, G.B. Schaffer, and D.H. StJohn: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1651–55.

W. Khalifa, F.H. Samuel, and J.E. Gruzleski: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 807–25.

E. Cinkilic, C.D. Ridgeway, X. Yan, and A.A. Luo: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 5945–56.

M.V. Kral, P.N.H. Nakashima, and D.R.G. Mitchell: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1987–97.

L.A. Narayanan, F.H. Samuel, and J.E. Gruzleski: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1761–73.

X. Zhang, D. Wang, H. Nagaumi, Y. Zhou, Yu. Wei, X. Chong, X. Li, and H. Zhang: J. Alloys Compd., 2022, vol. 901, 163523.

S.G. Shabestari, T. Mahmudi, M. Emamy, and T. Campbell: Int. J. Cast Met. Res., 2002, vol. 15, pp. 17–24.

J.Y. Hwang, H.W. Doty, and M.J. Kaufman: Mater. Sci. Eng. A, 2008, vol. 488, pp. 496–504.

E. Cinkilic, M. Moodispaw, J.Y. Zhang, J.S. Miao, and A.A. Luo: Metall. Mater. Trans. A, 2022, vol. 53A, pp. 2861–73.

A. Gorny, J. Manickaraj, Z.H. Cai, and S. Shankar: J. Alloys Compd., 2013, vol. 577, pp. 103–24.

H. Becker, T. Bergh, P.E. Vullum, A. Leineweber, and Y. Li: Materialia, 2019, vol. 5, 100198.

Z.P. Que and C.L. Mendis: J. Alloys Compd., 2020, vol. 836, 155515.

C. Puncreobutr, A.B. Phillion, J.L. Fife, P. Rockett, A.P. Horsfield, and P.D. Lee: Acta Mater., 2014, vol. 79, pp. 292–303.

J.S. Wang, P.D. Lee, R.W. Hamilton, M. Li, and J. Allison: Scr. Mater., 2009, vol. 60, pp. 516–19.

F.H. Samuel, P. Ouellet, A.M. Samuel, and H.W. Doty: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2871–84.

A.M. Samuel, A. Pennors, C. Villeneuve, F.H. Samuel, H.W. Doty, and S. Valtierra: Int. J. Cast. Metal. Res., 2000, vol. 13, pp. 231–53.

B. Closset and J.E. Gruzleski: Metall. Trans. A, 1982, vol. 13, pp. 945–51.

S.S.S. Kumari, R.M. Pillai, T.P.D. Rajan, and B.C. Pai: Mater. Sci. Eng. A, 2007, vol. 460, pp. 561–73.

A.M. Samuel, F.H. Samuel, and H.W. Doty: J. Mater. Sci., 1996, vol. 31, pp. 5529–39.

C. Villeneuve and F.H. Samuel: Int. J. Cast. Metal. Res., 2016, vol. 12, pp. 145–60.

Y.H. Cho, H.C. Lee, K.H. Oh, and A.K. Dahle: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2435–48.

J. Campbell: Casting Alloys, Butterworth-Heinemann, Boston, 2015, pp. 223–340.

X. Cao and J. Campbell: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1409–20.

W. Khalifa, F.H. Samuel, J.E. Gruzleski, H.W. Doty, and S. Valtierra: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1017–32.

P. Ashtari, H. Tezuka, and T. Sato: Mater. Trans., 2003, vol. 44, pp. 2611–16.

S.G. Shabestari, M. Keshavarz, and M.M. Hejazi: J. Alloys Compd., 2009, vol. 477, pp. 892–99.

S. Terzi, J.A. Taylor, Y.H. Cho, L. Salvo, M. Suéry, E. Boller, and A.K. Dahle: Acta Mater., 2010, vol. 58, pp. 5370–80.

J.M. Yu, N. Wanderka, A. Rack, R. Daudin, E. Boller, H. Markötter, A. Manzoni, F. Vogel, T. Arlt, I. Manke, and J. Banhart: Acta Mater., 2017, vol. 129, pp. 194–202.

P.K. Panday and K. Schubert: J. Less Common Met., 1969, vol. 18, pp. 175–202.

J.M. Yu, N. Wanderka, A. Rack, R. Daudin, E. Boller, H. Markotter, A. Manzoni, F. Vogel, T. Arlt, I. Manke, and J. Banhart: J. Alloys Compd., 2018, vol. 766, pp. 818–27.

S. Foss, A. Olsen, C.J. Simensen, and J. Tafto: Acta Crystallogr. B, 2003, vol. 59, pp. 36–42.

H.H. Xi, J.J. Xu, X. Yuan, W.Q. Ming, Z. Zhang, and J.H. Chen: Mater Charact, 2023, vol. 199, 112839.

J. Li, F.S. Hage, X. Liu, Q. Ramasse, and P. Schumacher: Sci. Rep., 2016, vol. 6, p. 25244.

J. Barrirero, M. Engstler, N. Ghafoor, N. de Jonge, M. Oden, and F. Mucklich: J. Alloys Compd., 2014, vol. 611, pp. 410–21.

K. Nogita, H. Yasuda, K. Yoshida, K. Uesugi, A. Takeuchi, Y. Suzuki, and A.K. Dahle: Scr. Mater., 2006, vol. 55, pp. 787–90.

M. Timpel, N. Wanderka, R. Schlesiger, T. Yamamoto, N. Lazarev, D. Isheim, G. Schmitz, S. Matsumura, and J. Banhart: Acta Mater., 2012, vol. 60, pp. 3920–28.

F. Yilmaz, O.A. Atasoy, and R. Elliott: J. Cryst. Growth, 1992, vol. 118, pp. 377–84.

B. Suárez-Peña and J. Asensio-Lozano: Scripta Mater., 2006, vol. 54, pp. 1543–48.

E. Vandersluis, C. Ravindran, D. Sediako, A. Elsayed, and G. Byczynski: J. Alloys Compd., 2019, vol. 792, pp. 240–49.

B. Predel: Fe-Sr (Iron-Strontium): Datasheet from Landolt-Börnstein—Group IV Physical Chemistry Volume 5E: “Dy-Er-Fr-Mo” in SpringerMaterials. Springer, Berlin, 2006.

B. Predel: Mn-Sr (Manganese-Strontium): Datasheet from Landolt-Börnstein—Group IV Physical Chemistry Volume 5H: “Li-Mg-Nd-Zr” in SpringerMaterials. Springer, Berlin, 2006.

Alan Prince and MSIT® Materials Science International Team: Al-Fe-Sr Ternary Phase Diagram Evaluation Phase diagrams, crystallographic and thermodynamic data: Datasheet from MSI Eureka in SpringerMaterials. MSI Materials Science International Services GmbH, 1993.

Alan Prince and MSIT® Materials Science International Team: Al-Mn-Sr Ternary Phase Diagram Evaluation Phase diagrams, crystallographic and thermodynamic data: Datasheet from MSI Eureka in SpringerMaterials. MSI Materials Science International Services GmbH, 1993.

W. Yi, G.C. Liu, Z. Lu, J.B. Gao, and L.J. Zhang: J. Mater. Sci. Technol., 2022, vol. 112, pp. 277–90.

J.M. Yu, N. Wanderka, G. Miehe, and J. Banhart: Intermetallics, 2016, vol. 72, pp. 53–61.

Acknowledgments

This material is based upon work supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Advanced Manufacturing Office Award Number DE-EE0007897, awarded to The REMADE Institute, a division of Sustainable Manufacturing Innovation Alliance Corp. This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.”

Author information

Authors and Affiliations

Contributions

NB: conceptualization, validation, and writing—original draft preparation; MM: characterization, validation, conceptualization, and writing—review and editing; EC: conceptualization, methodology, and investigation; JM: characterization testing, investigation, and writing—review and editing; AL: conceptualization, investigation, resources, writing—review and editing, and supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Balasubramani, N., Moodispaw, M., Cinkilic, E. et al. Strontium Effects on the Formation of Iron-Intermetallic Phases in Secondary Al–9Si–0.6Fe Alloys. Metall Mater Trans A 55, 550–568 (2024). https://doi.org/10.1007/s11661-023-07267-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07267-7