Abstract

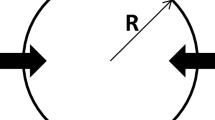

Reduction of iron ore–coal composite pellets at a rotary hearth furnace (RHF) could be an energy efficient process under optimized design and operating conditions. The present study aims to analyze such process through process models for optimization of thermal efficiency. In the present article, a mathematical model has been described to calculate the rate parameters, evolution of various phases, temperature profile, and thermal efficiency of the process. Experiments have been carried out for reduction of iron ore–coal composite pellets in multi-layers at laboratory scale RHF. It has been observed that while the total average time of reduction for three layer bed at 1,200 °C is 48 min, the average time of reduction at 1,300 °C is estimated as 11 min only. The thermal efficiency of the process is found to be maximum for three layer bed and least for the single layer bed. Extra fuel in terms of carbon equivalent has also been reported.

Similar content being viewed by others

References

Burgess J M, ISIJ Int 31 (1991) 408.

Wang C, Larsson M and Ryman C, Grip C-E, Wikstrom J-O, Johnsson A, and Engdahl J, Int J Energy Res 32 (2008) 1092.

Kikuchi S, Ito S, Kobayashi I, Tsuge O, and Tokuda K, Kobelco Technol Rev 29 (2010) 77.

Chatterjee A, Sponge Iron Production by Direct Reduction of Iron Oxide, PHI, India (2010) 376.

Haldar S, and Fruehan R J, Metall Mater Trans B 39B (2008) 796.

Seaton C E, Foster J S, and Velasc O J, Trans ISIJ 23 (1983) 490.

Sun S, and Lu W K, ISIJ Int 39A (1999) 130.

Donskoi E and McElwain D L S, and Wibberley L J, Metall Mater Trans B 34B (2003) 255.

Chowdhury G M, Roy G G, and Roy S K, Metall Mater Trans B 39 (2008) 160.

Kalyanmoy D, Optimization for Engineering Design, Prentice Hall of India Pvt. Ltd., New Delhi (1998) 340.

Donskoi E, and McElwain D L S, Metall Mater Trans B 34B (2003) 93.

http://www.worldsteel.org/dms/internetDocumentList/downloads/steel-by-topic/Data-collection-user-guide_v6/document/Data%20collection%20user%20guide.pdf. World Steel Association, CO2 Emission Data Collection, User Guide, Version 6, p. 19.

Acknowledgments

The authors acknowledge the financial help from the project sponsored by Ministry of Steel, Govt. of India, to the Steel Technology Center at IIT Kharagpur, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumari, V., Roy, G.G. & Sen, P.K. Mathematical Model to Estimate the Rate Parameters and Thermal Efficiency for the Reduction of Iron Ore–Coal Composite Pellets in Multi-layer Bed at Rotary Hearth Furnace. Trans Indian Inst Met 68, 109–116 (2015). https://doi.org/10.1007/s12666-014-0434-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-014-0434-3