Abstract

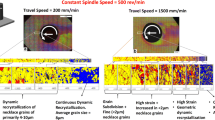

The influence of friction stir welding on the microstructure development and its role on residual stress distribution in the weldment and mechanical properties has been investigated. The study also focused on the impact of post weld heat treatment on the microstructure and mechanical properties as well as on residual stress distribution. The weld nugget region contained fine equiaxed grains as a result of thermo-mechanical working. Hardness survey showed that nugget region is soft due to precipitates dissolution. Weld joint exhibited lower strength as compared to the parent metal. Post weld Solution Treatment and Aging (STA) of longitudinal welds resulted in strength and ductility equivalent to that of parent metal while transverse weld tensile strength and ductility were lower than that of parent metal even after post weld STA. Residual stress distribution profiles across the weld region are asymmetric with respect to weld centerline, with the largest residual; stress gradients occurring on the advancing side of the weld. Within the region inside the shoulder diameter, residual stress is entirely compressive. Welds exhibited tensile residual stresses in post weld STA condition

Similar content being viewed by others

References

Cam G, Dos Santos J F, and Kocak M, “Laser and electron beam weldability of Al-alloys: literature review”, GKSS Report 97/E/25, IIW Document IX-1896-98, GKSS Research Centre, Geesthacht, (1997).

Madhusudhan Reddy G, Sammaiah P, Murthy C V S, and Mohandas T, in Proc of National Conference on Processing of Metals, PSG College of Technology, Coimbatore, India (2002) p 33.

Kou S, “Welding metallurgy and weldability of high strength aluminum alloys”, Welding Research Council Bulletin, 320 (1986).

Thomas W M, Nicholas E D, Needham J C, Murch M G, Temple-Smith P and Dawes C J, Friction stir butt welding, International Patent Application No. PCT/GB92/02203; GB patent Application No. 9125978.8, 1991; US Patent No. 5460317, 1995.

Chen C M and Kovacevic R, Machine Tools & Manufacture, 43 (2003) 1319.

Song M and Kovacevic R, Journal of Machine Tool and Manufacturing, 43 (2003) 605.

Ying Li, Murr L E and McClure J C, Materials Science and Engineering A, 271 (1999) 213.

Fonda R W, Bingert J F and Colligan K J, Scripta Materialia 51 (2004) 243.

Su J Q, Nelson T W, Mishra R and Mahoney M, Acta Materialia, 51 (2003) 713.

Sutton M A, Reynolds A P, Wang D Q and Hubbard, J. Eng. Mater. Technol., 124 (2002) 215.

James M R and Cohen J B, “The measurement of residual stresses by X-ray diffraction technique”, Treatise on Materials Science and Technology, H. Herman (ed.), Academic Press, NY, 19A (1980) p 1.

Liu G, Murr L E, Niou C S, McClure J C and Vega F R, Scripta Materialia 37 (1997) 355.

Huijie Liu, Fujii H, Maeda M and Nogi, Journal of Materials Science Letters, 22 (2003) 1061.

Lee W B, Yeon Y M, and Jung S B, Materials Science and Technology, 19 (2003) 1513.

Somasekharan A C and Murr L E, Materials Characterization, 52 (204) 49.

Hatch J E, “Aluminum: Properties and Physical Metallurgy”, Aluminum Association, Inc., Published by ASM, Materials Park, Ohio, (1984).

Krishnan K N, Journal of Materials Science, 37 (2002) 473.

Charit I, Mishra R S and Mahoney M W, Scripta Materialia 47 (2002) 631.

Feng J C, Chen Y C and Liu H J, Materials Science and Technology, 22 (2006) 86.

Mahoney M W, Rhodes C G, Flintoff J G, Spurling R A and Bingel W H, Metallurgical and Materials Transactions A, 29A (1998) 1955.

Rhodes C G, Mahoney M W, Bingel W H, Spurling R A and Bampton C C, Scripta Materialia, 36 (1997) 69.

Mondolfo L F, Aluminum Alloys: Structure and Properties, Butterworths, (1976) p 644.

Yutaka S, Sato, Hiroyuki Kokawa, Masatoshi Enomoto, Shigetoshi Jogan and Takenori Hashimoto, Metallurgical and Materials Transactions A, 30 (1999) 3125.

Lima E B F, Wegener J, Dalle Donne C, Goerigk G, Wroblewski T, Buslaps T, Pyzalla A R and Reimers W, Z. Metallkd., 94 (2003) 908.

Gould J E, Lienert T J and Feng Z, Journal of Materials & Manufacturing, 107 (1998) 1093.

Xu S, Deng X, Reynolds A P and Seidel T U, Science and Technology of Welding and Joining, 6 (2001) 191.

Liming K E, Xing L I and Indacochea J E, Metallurgical and Materials Transactions B, 35 (2004) 153.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Madhusudhan Reddy, G., Mastanaiah, P., Sata Prasad, K. et al. Microstructure and mechanical property correlations in AA 6061 aluminium alloy friction stir welds. Trans Indian Inst Met 62, 49–58 (2009). https://doi.org/10.1007/s12666-009-0007-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-009-0007-z