Abstract

From the perspective of economy and safety, balancing gas contained in the pore space of rocks is extremely essential, predominantly to establishments dealing with extraction of mineral resources. One of the main methods of evaluating the amount and composition of gas contained in the pore space of a rock is releasing the gas as a result of comminuting the investigated rock material. In the case of cupriferous rocks, effective comminution is a very difficult task, due to the strength properties of these rocks. The present paper discusses the results of studies into the gas content of cupriferous rocks, obtained by means of an original device named the GPR analyzer. The research was done on 41 samples of dolomites and anhydrites from various areas of two copper mines located in Poland: “Rudna” and “Polkowice-Sieroszowice.” For all samples, on the basis of microscope analyses performed on cuts and polished sections, the open porosity, closed porosity, and total porosity were determined. In the case of the dolomite samples, the total porosity variability fell in the range of 4.75–23.05%, and in the case of the anhydrite samples—in the range of 3.87–16.60%. The maximum gas content of the dolomite samples was 166.67 cm3/kg, and of the anhydrite samples—84.66 cm3/kg. In some of the studied samples, the presence of methane was confirmed. Toxic gases, such as H2S, were not found. The main gas in the pore space of the investigated rocks was nitrogen. Knowing the amount of the released gas and the value of the closed porosity in the investigated samples, the authors were able to estimate the pore pressure of the gas, whose maximum value was 0.583 MPa.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The extraction of rocks is often accompanied by problems connected with the presence of gas contained in the pore space of these rocks. Regardless of the fact whether the gas in rock pores is viewed as a desirable energy resource or as a risk factor-generating hazard during the exploitation process, its presence in a rock seam should be ascertained. Knowledge of the amount of gas per unit volume is the essential indicator describing both the profitability of the gas exploitation and the level of gas and gaso-geodynamic hazards. In a lot of countries, gas content of rocks is the basis for categorization of gas and outburst hazards (Skoczylas and Wierzbicki 2014).

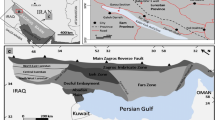

One of the main methods of balancing the amount and composition of gas contained in a rock is comminuting this rock so that it is reduced to grains of a size comparable with the size of its pores. Comminuting performed under hermetic conditions releases the gas, whose amount and concentration may then be measured. At the Strata Mechanics Research Institute of the Polish Academy of Sciences, an innovative system for balancing gas contained in rocks was constructed, which made it possible to carry out a cycle of measurements of the gas contained in dolomites and anhydrites (Kudasik and Skoczylas 2017). The measuring system consists of a high-speed, hermetic percussive mill equipped with a set of appropriate sensors of pressure, concentration, and temperature, as well as control systems and data acquisition systems. The paper discusses the results of balancing gases contained in rocks from the copper mines located in the Legnica-Głogów Copper Belt, Poland, where the hazard connected with the presence of gases accompanying the strata exploitation has been increasing in recent years (Wierzbicki and Młynarczuk 2013; Pajdak et al. 2017). Evaluating the content of gas in rocks of high strength is a difficult task, and the results of research of this type are seldom published.

Problems connected with the presence of gas in a rock are most frequently associated with methane contained in hard coal seams. In particular, gaso-geodynamic hazards (including outburst hazards), linked to the co-occurrence of a solid and gaseous resource, are predominantly connected with the coal–methane system. During an outburst, the gas accumulated in the pore structure of a rock does work by comminuting the rock material and transporting it down the excavation (Beamish and Crosdale 1998; Cao et al. 2001; Topolnicki et al. 2004; Skoczylas 2012; Wang et al. 2013; Jiang et al. 2015). With the specific needs of the coal mining industry in mind, various research methods have been developed, which make it possible to evaluate the methane content of a given coal seam (Szlązak and Korzec 2016). From the point of view of exploitation, gas occurring in underground deposits of different types seldom poses a problem.

The outburst of gas and dolomite that took place in the “Rudna” copper mine in Poland, at the depth of 1200 m, was the first such incident in the mining history (Wierzbicki and Młynarczuk 2013). The risk connected with the presence of numerous natural hazards, including gas-related hazards, grows with the depth of exploitation (Hargraves 1983; Díaz Aguado and González Nicieza 2007; Xue et al. 2014). The exploitation of copper deposits located at increasingly deeper levels results in the appearance of new hazards, previously unknown to the copper mining industry. The aforementioned gas and dolomite outburst from the “Rudna” mine proved that it is necessary to constantly investigate the gas content of exploited deposits, including cupriferous rocks.

Dolomites and anhydrites represent rocks characterized by a low level of structural diversification, massive and compact structure, and low porosity (Godyń 2016; Pajdak et al. 2017; Pajdak and Kudasik 2017). Due to the specific circumstances connected with the deposition of dolomite, the porosity comprises both the open and closed pores. According to the International Union of Pure and Applied Chemistry classification system (IUPAC 1985), from the perspective of the size of the dolomite pores, the predominant type of pores are mesopores, whose diameter falls in the range of 0.002–0.050 µm, and macropores, whose diameter exceeds 0.050 µm. The pores are of various size and shape; they can serve to transport gases in a rock mass as part of their migration process, or simply function as empty spaces with no contact with the external environment. Part of the pore structure of a rock is in contact with the environment (open porosity), which results in release and transportation of the gas included in it. The other part is isolated from the environment: This is closed porosity. Gas deposited in the closed pores usually remains there permanently; it may also be the case that it is gradually released, but very slowly and in very small quantities.

When it comes to the analysis of the rock–gas system, it inevitably turns out that significant similarities between hard coal and cupriferous rocks are hard to find. The mechanisms of gas accumulation and transportation in the pore space of both types of rock differ considerably. Both anhydrites and dolomites are virtually impermeable in relation to gases (Luhmann et al. 2014; Feng et al. 2017). Also, in these rocks, the phenomena of sorption and diffusion occur only to a small degree, in contrast to hard coal, which displays high sorption properties, and complex mechanisms of gas transportation that occur within the coal matrix. Gas included in cupriferous rocks is free gas, located in the pore structure. Due to these differences, it is impossible to directly adapt the methods of evaluating the gas content of coal to balancing gas included in cupriferous rocks.

In order to release the gas accumulated in the pore space of a rock characterized by a very low degree of permeability, it is necessary to comminute this rock so that it is reduced to grains of a size comparable with the size of its pores. All the methods connected with a time observation of the release of gas from a lump sample would prove ineffective.

The present paper discusses the results of research into the gas content of cupriferous rock samples, carried out with the GPR analyzer—an original instrument of gas contained in rocks (Kudasik and Skoczylas 2017).

Research equipment

The constructed instrument for balancing gas contained in rocks (Fig. 1), called the GPR analyzer, consists of two basic functional blocks: a mill for comminuting rocks and an analyzer equipped with appropriate sensors of gas concentration, of pressure, and of temperature.

A rock sample is placed inside a hermetic measuring chamber of the instrument, where it is comminuted by means of a rotating knife. The knife is propelled by a high-speed brushless electric motor, whose power is 2.2 kW. The maximum rotational speed of the knife is 21,000 rpm. Such power of the motor and such rotational speed of the knife make it possible to comminute a sample of a cupriferous rock weighing 30–50 g to grains of a size expressed in single micrometers, in less than a minute.

The upper lid of the measuring chamber of the instrument is equipped with the sensors of gases, pressure, and temperature. In the lid, a reference chamber has also been installed, in relation to which changes in the pressure and concentration of gases released from the sample into the measuring chamber during the measurement procedure are assessed. The amount of gas contained in the pore space of the rocks is balanced on the basis of the change in the pressure of gas in the measuring chamber, which is a result of comminuting the rock sample and releasing the gas included in it. On the basis of the change in concentration, the share of particular components (CH4, H2S) of the mixture of gases released from the sample is determined.

Research material

In the research into balancing gas contained in the pore space of cupriferous rocks, samples collected from various areas of the “Rudna” and “Polkowice-Sieroszowice” copper mines, Poland, were used. Thirty-one core fragments were assigned numbers from 1 to 31. Some of the samples came from the same core; however, the fragments used in the research could actually be a few (sometimes more than ten) meters away from each other. These samples were assigned the same numbers (e.g., sample 7v1 and 7v2). Altogether, 41 samples of dolomites and anhydrites were studied.

Each sample was analyzed from the physical and structural–textural perspective so that its helium density and total porosity (open and closed) could be determined. The gas content of the research material was studied using the original GPR analyzer—an instrument of gas contained in rocks. The research material was constituted by cupriferous rock portions weighing 30–50 g, reduced to grains of 20–40 mm in size. Figure 2 presents a dolomite sample before and after it was comminuted by means of the GPR analyzer.

Measurement procedure

According to the adopted measurement procedure, each sample investigated by means of the GPR analyzer was reduced to grains of 20–40 mm in size prior to the start of the test and then divided into three parts:

-

A single lump which served as the material for determining the helium density of the sample,

-

Fragments out of which colored cuts and polished sections were to be made, and

-

Portions weighing between 30 and 50 g (the mass of each sample was precisely determined) for balancing the amount and composition of gas contained in the pore space.

The helium density of the samples was determined by means of the AccuPyc II 1340 helium pycnometer produced by Micromeritics.

The porosity of the samples was determined on the basis of point-tracked quantitative analysis performed on the colored cuts and polished sections. The analyses were performed using the AXIOPLAN polarizing microscope by ZEISS and a computer-controlled mechanical table—XYZ. By means of a CCD camera, the image from the optical microscope was transferred to a computer monitor. The magnification used was 200×. The microscope analyses were carried out in transmitted light (colored thin cuts) and reflected light (polished sections). The size of each colored cut and polished section was 20 mm × 20 mm, and they were all investigated with respect to 2500 points contained within the square grid. Each analyzed point of the grid located at the intersection of the cross-hairs of the microscope was ascribed a particular feature (porous/solid material). Statistically, an analysis of 2500 points made it possible to determine particular porosities of the samples.

In order to properly estimate the percentage value of the total porosity of the rock samples, the so-called polished sections were prepared, i.e., ground and polished fragments of rocks to be analyzed in reflected light. The polished and smooth surface of such a laboratory preparation of a rock reflects light, which is demonstrated by clearly visible minerals of various shades of gray (carbonates and sulfates) and ore-bearing minerals reflecting a very strong or even glaring light. The fragments of a rock where pores and fissures occur are not polished, and therefore these spots reflect a weak light, which is demonstrated by dark gray or almost black areas (Fig. 3).

By analyzing the thin cuts, percentage values of the open porosity ε0 of the investigated rocks were determined. For this purpose, the piece of a deposit out of which a cut is to be made is saturated with resin in a contrasting color. The dye penetrates the open pores, which—after the cut has been made—become the only clearly visible pores (the blue areas—cf. Fig.4.). Due to point-tracked quantitative analysis performed on a colored thin cut, it is possible to calculate the percentage content of such pores in a rock.

Stereological analyses, in turn, made it possible to determine the total porosity using the polished sections (cf. Fig. 3) and the open porosity using the colored cuts (cf. Fig. 4). On the basis of the difference between the two, the closed porosity of the investigated rocks was established.

The gas content of the investigated rocks was studied with the original GPR analyzer. All the measurements were carried out under constant temperature of 25 °C, which was possible due to placing the analyzer inside the Q-Cell 40 thermostatic cabinet.

Balance of gas content

In the case of the constructed original device, the amount of gas contained in a rock is assessed by registering changes in the pressure ∆p inside the measuring chamber, in which the sample is comminuted. The investigated samples were comminuted within ca. 30–40 s, which was enough to reduce each sample to grains of a size comparable with the size of its pores. The comminution of the samples generates huge power in the GPR analyzer, which results in a temporary rise of temperature. Figure 5 presents some examples of changes in the temperature inside the measuring chamber during the comminution of five different rock samples. On the basis of these changes, we can observe that the process of comminuting the rock material caused a temporary increase of ca. 5–13 °C in the temperature of the measuring chamber (as far as the samples presented on the graph are concerned). As for the remaining samples, an increase in the temperature caused by the process of their comminution did not exceed 13 °C. The differences in temperature leaps displayed by particular samples (e.g., when we compare sample 18v2—a 5 °C increase, and sample 15—a 13 °C increase) are due to the fact that the time span of the comminution process was different for each sample. The temperature of the measurement after the comminution was reached after ca. 200 min. Therefore, it was concluded that the conditions of the measurement got stabilized after the necessary minimum period of 200 min—and only after this time the end readings of the sensors were checked.

Figure 6 presents some examples of changes in the pressure ∆p inside the measuring chamber caused by the comminution of sample 16v2 and the release of gas that followed the comminution.

During the process of comminuting the sample, the pressure in the measuring chamber increases due to a number of factors, among which there are: the release of gas from the opened pore structure of the rock, rising temperature, and other processes connected with the rotational motion of the rock grains and gas in the measuring chamber during the comminution process. Starting with the moment when the comminution process ends, pressure ∆p in the measuring chamber decreases gradually until it reaches the boundary value. By reading the value of ∆p at the moment of stabilization of the measurement conditions, we are able to determine the pore pressure of gas contained in the pore space of a rock, using the following formula:

where: \( \Delta M ( {\text{m}}^{3} ) \) is the amount of gas contained in the investigated rock sample (under normal conditions), \( T(K) \) is the temperature within the measuring chamber during the measurement, \( R \left( {\frac{\text{J}}{{{\text{mol}} \cdot {\text{K}}}}} \right) \) is the universal gas constant, \( V_{p} ({\text{m}}^{3} ) \) is the volume of the closed pores of the rock sample: \( V_{p} = V_{s} \cdot \varepsilon_{c} = \frac{m}{\rho } \cdot \varepsilon_{c} \), \( V_{s} ({\text{m}}^{3} ) \) is the volume of the rock sample, \( m ({\text{g}}) \) is the mass of the rock sample, \( \rho \left({\frac{\text{g}}{{{\text{m}}^{3} }}} \right) \) is the density of the rock sample, \( \varepsilon_{c} ( - ) \) is the closed porosity of the rock sample, \( V_{\text{m}} \left( {\frac{{{\text{m}}^{3} }}{\text{mol}}} \right) \) is the molar volume of gas (under normal conditions), \( p_{\text{p}} ({\text{Pa}}) \) is the pore pressure of gas in a rock, determined on the basis of the balance of equations describing the boundary conditions (before and after the process of comminuting the sample):

\( M_{0} ({\text{m}}^{3} ) \) is the amount of gas surrounding the sample before the comminution process, \( M_{\infty } \left[ {{\text{m}}^{3} } \right] \) is the amount of gas in the measuring chamber after comminuting the sample, \( p_{\text{atm}} ({\text{Pa}}) \) is the atmospheric pressure, \( V_{0} ({\text{m}}^{3} ) \) is the free space surrounding the sample (the volume of the measuring chamber minus the volume of the rock sample), \( \Delta p ({\text{Pa}}) \) is the change of pressure in the measuring chamber in relation to the reference chamber, resulting from comminuting the sample and the release of gas.

In the case of the presented sample 16v2 (Fig. 6), the end value of the differential pressure ∆p inside the measuring chamber, after the comminution of the sample and stabilization of the measurement conditions, was 0.66 kPa. Knowing the closed porosity of the sample, as well as its density, we can use formula (2) to establish the pore pressure of gas \( (p_{\text{p}} = 0.276 \,{\text{MPa}}) \) and formula (3) to establish the amount of gas released from the pore space of the sample \( \left( {\Delta M = 2.08 \,{\text{cm}}^{3} } \right) \). In the analyzed case, the gas content of the investigated dolomite sample was 88.22 cm3/kg.

The composition of the gas mixture contained in a rock sample is established using the readings of gas concentration sensors (H2S, CH4), based on the balance of percentage concentrations. For example, the amount of methane contained in a rock sample is calculated by means of the following formula:

where \( C_{{{\text{CH}}_{4} }} ( - ) \) is the concentration of methane in the measuring chamber after the comminution process.

Results

The examples of changes of the pressure ∆p inside the measuring chamber, caused by the comminution of the four samples which differs the most when it comes to their gas content, are presented in Fig. 7.

In the case of samples 1 and 16v1, the pore pressure of the gas included in their pore space was estimated at approximately 0.185 and 0.522 MPa, respectively. In the case of sample 24, pressure ∆p in the measuring chamber after the comminution of the sample reached the initial value, corresponding to the value of the pressure inside the chamber before the comminution (∆p = 0 kPa). Here, the pore pressure equaled the atmospheric pressure. In the case of sample 2, the end value of the pressure in the measuring chamber took on a negative value (∆p = − 0.33 kPa) in relation to the reference chamber. This suggests that there was very little gas in the pore space of this particular sample, and the value of the pore pressure was close to vacuum. A similar situation took place in the case of samples 6v1 and 15. The results of all the measurements of the gas content of cupriferous rock samples have been tabulated in Table 1.

The total porosity of the investigated samples fell in the range of 3.87% (sample 22)–18.60% (sample 16); in one case, the result exceeded 23% (sample 19). The measurement of the gas content performed on 41 samples showed that the maximum gas content value was 166.67 cm3/kg (sample 16v1). In the case of 14 samples, the value of gas content was lower than 20 cm3/kg; with another 15 samples, the gas content values fell in the range from 20 to 40 cm3/kg; in the case of yet another group, comprising 10 samples, the gas content values fell in the range from 40 to 100 cm3/kg. Only in two cases (samples 16v1 and 25) did the gas content exceed 100 cm3/kg.

On the basis of the known closed porosities of particular samples, the values of the pore pressure of gas (the absolute pressure) were determined. In 10 cases, the pressure of the gas filling the closed pores of the rocks was lower than the atmospheric pressure. In 18 cases, the pore pressure fell in the range of 0.1–0.2 MPa; in 8 cases—of 0.2–0.3 MPa; in 3 cases—of 0.4–0.5 MPa. The highest values of the pore pressure of gas were displayed by 2 samples, 16v1 and 25 (0.522 and 0.583 MPa, respectively).

It is extremely vital to know if the pore space of a given rock contains explosive gases (such as methane) or toxic gases (such as hydrogen sulfide), as this knowledge has a direct impact on the safety of the exploitation process. In the investigated rock samples, no trace of hydrogen sulfide was found. At the same time, the concentration of methane inside the measuring chamber after comminuting sample 16v2 increased by 0.29%, which corresponds to a release of 2.58 cm3 of methane from a sample weighing 1 kg. Another gas released from the sample was nitrogen, which—as the main component of the gas mixture contained in the pore pressure of the dolomite—was found in the post-outburst masses collected from the spot in the “Rudna” mine where the tragic incident happened in 2009 (Wierzbicki and Młynarczuk 2013).

Discussion

In the case of hard coal, the extraction of which is inevitably connected with the simultaneous release of gas constituting an enormous hazard from the perspective of the safety of exploitation, we do know a number of methods that let us determine the gas content of coal beds. However, the content of gas in the pore structure of other rocks is a field that, so far, has not been studied in such a thorough way. The number of available research papers that would let us know what types of gases (and in what amount) can be found in cupriferous rocks is very limited. Thus, the discussion concerning the evaluation of the obtained results of the research into the gas content of dolomites and anhydrites is the most sensible when we relate the issue to the measurements performed on hard coal.

The content of methane in hard coal usually falls in the range of 2–8 cm3/g. If this content exceeds 8 cm3/g, we are faced with a considerable hazard of explosion or outbursts of rocks and gas (Lama and Bodziony 1998). The maximum values of methane content in coal beds, established in the course of measurements, may reach 20 cm3/g (Fisne and Esen 2014). In the case of hard coal, the majority of the accumulated gas is the sorptively bonded gas. If we assume that the typical porosity of hard coals is between 5 and 10% (Rodrigues and Lemos de Sousa 2002; Bukowska et al. 2012; Ramandi et al. 2016), then—for the typical values of the seam pressure, i.e., 0.2–0.6 MPa (Skoczylas 2012)—the amount of methane in free state shall fall in the range of 0.067–0.400 cm3/g (the upper limit of this range concerns the coal displaying the highest porosity, under the highest pore pressure).

When we juxtapose the investigated dolomite and anhydrite samples with hard coal, we shall see that, statistically, they contain ca. 100 times less gas per unit mass of rock. However, in the case of dolomites and anhydrites, the phenomenon of sorption is marginal, and the dominant gas in their pore structure is nitrogen. Therefore, the total amount of the balanced gas is in the form of free gas. The highest gas contents balanced by the authors of the present paper oscillated around 0.16 cm3/g, which is close to the typical values of the free methane content in hard coal (Liu et al. 2013; Baran et al. 2014).

From the perspective of gaso-geodynamic hazards, taking into account the fact that dolomites and anhydrites are much more firm than hard coal, even the highest known values of gas content guarantee safety of exploitation. The classical theory of gas and rock outbursts assumes that the value of the energy of the gas accumulated in the rock pores has to be high enough for the gas to do work when destroying the rock and transporting it down the excavation (Wierzbicki and Skoczylas 2014; Sobczyk 2014; Skoczylas 2014; Tian et al. 2016). The high porosity values of dolomite (from 15.6 to 16.8%) and the pore pressure of gas exceeding 5.3 MPa were among the main reasons for the outburst of dolomite and other rocks that occurred in the “Rudna” copper mine in Poland in September 2009 (Wierzbicki and Młynarczuk 2013).

In the case of all the samples investigated as part of this research (cf. Table 1), the majority of the obtained porosity values and all the values of the pore pressure of gas were much lower than the values obtained for the post-outburst masses from the “Rudna” mine. Thus, comparing the results of the research into the gas content with the results obtained for the post-outburst masses, it seems right for the authors to conclude that the area of the copper ore deposit from which the samples used in the research discussed in this paper were collected should be regarded as safe.

Conclusions

As part of the conducted research into the gas content of rocks, 41 samples of dolomites and anhydrites from various areas of two copper mines located in Poland—“Rudna” and “Polkowice-Sieroszowice”—were studied. The research was carried out by means of an original analyzer named GPR. Simultaneously, the same research material was used to perform microscope analyses of cuts and polished sections, on the basis of which the open porosity, closed porosity, and total porosity were determined.

In the case of the dolomite samples, the total porosity variability fell in the range of 4.75–23.05%, in the case of the anhydrite samples—in the range of 3.87–16.60%. The maximum measured gas content of the dolomite samples was 166.67 cm3/kg, and of the anhydrite samples—84.66 cm3/kg. Knowing the value of the closed porosity in the investigated samples, as well as their gas content, the authors were able to determine the value of the pore pressure of the gas. In 10 cases, the pressure of the gas filling the closed pores of the rocks was lower than the atmospheric pressure. In the remaining 31 cases, the pore pressure variability fell in the range of 0.1–0.6 MPa. The highest determined values of the pore pressure were 0.522 and 0.583 MPa.

In some of the studied samples, the presence of methane was confirmed, whereas toxic gases, such as H2S, were not found. The main gas in the pore area of the investigated rocks was nitrogen.

The obtained results of the conducted research into the gas content of rock samples significantly exceed the values determined by other scientists who investigated the material from the same research area (by up to 30 cm3/kg (Janiga and Kania 2014) and by up to 41 cm3/kg (Markiewicz and Becker 2009).

References

Baran P, Zarębska K, Krzystolik P, Hadro J, Nunn A (2014) CO2-ECBM and CO2 sequestration in Polish coal seam—experimental study. J Sustain Min 13(2):22–29

Beamish B, Crosdale PJ (1998) Instantaneous outbursts in underground coal mines: an overview and association with coal type. Int J Coal Geol 35:27–55

Bukowska M, Sanetra U, Wadas M (2012) Chronostratigraphic and depth variability of porosity and strength of hard coals in the Upper Silesian Basin. Mineral Resour Manag 28(4):151–166

Cao YX, He D, Glick DC (2001) Coal and gas outbursts in footwalls of reverse faults. Int J Coal Geol 48(1–2):47–63

Díaz Aguado MB, González Nicieza C (2007) Control and prevention of gas outbursts in coal mines, Riosa–Olloniego coalfield, Spain. Int J Coal Geol 69(4):253–266

Feng M, Wu P, Qiang Z, Liu X, Duan Y, Xia M (2017) Hydrothermal dolomite reservoir in the Precambrian Dengying Formation of central Sichuan Basin, Southwestern China. Mar Pet Geol 82:206–219

Fisne A, Esen O (2014) Coal and gas outburst hazard in Zonguldak Coal Basin of Turkey, and association with geological parameters. Nat Hazards 74(3):1363–1390

Godyń K (2016) Microscopic research of the pore space of dolomites of the Zechstein copper-bearing formation of Polkowice area. Trans Strat Mech Res Inst 18(3):43–53

Hargraves AJ (1983) Instantaneous outbursts of coal and gas: a review. Proc Australas Inst Min Metall 285(3):1–37

International Union of Pure and Applied Chemistry (1985) Physical Chemistry Division Commission on colloid and surface chemistry including catalysis: reporting physisorption data for gas/solid systems with special reference to the determination of surface area porosity. Pure Appl Chem 57(4):603–619

Janiga M, Kania M (2014) Degassing of rock samples—residual gas parameters. Naft Gaz 70(1):8–13

Jiang C, Xu L, Li X, Tang J, Chen Y, Tian S, Liu H (2015) Identification model and indicator of outburst-prone coal seams. Rock Mech Rock Eng 48(1):409–415

Kudasik M, Skoczylas N (2017) Analyzer for measuring gas contained in the pore space in rocks. Meas Sci Technol 28(10):105901

Lama RD, Bodziony J (1998) Management of outburst in underground coal mines. Int J Coal Geol 35(1–4):83–115

Liu A, Fu X, Wang K, An H, Wang G (2013) Investigation of coalbed methane potential in low-rank coal reservoirs—free and soluble gas contents. Fuel 112:14–22

Luhmann AJ, Kong X-Z, Tutolo BM, Garapati N, Bagley BC, Saar MO, Seyfried WE Jr (2014) Experimental dissolution of dolomite by CO2-charged brine at 100 °C and 150 bar: evolution of porosity, permeability, and reactive surface area. Chem Geol 380:145–160

Markiewicz A, Becker R (2009) The original extent of the Oldest Halite (Na1) in the southern part of the Fore-Sudetic Monocline (SW Poland). Geologia 35(3):327–348

Pajdak A, Kudasik M (2017) Structural and textural characteristic of selected copper-bearing rocks as one of the elements aiding in the assessment of gasogeodynamic hazard. Stud Geotech Mech 39(2):51–59

Pajdak A, Godyń K, Kudasik M, Murzyn T (2017) The use of selected research methods to describe the pore space of dolomite from copper ore mine, Poland. Environ Earth Sci 76:389

Ramandi HL, Mostaghimi P, Armstrong RT, Saadatfar M, Pinczewski WV (2016) Porosity and permeability characterization of coal: a micro-computed tomography study. Int J Coal Geol 154–155:57–68

Rodrigues CF, Lemos de Sousa MJ (2002) The measurement of coal porosity with different gases. Int J Coal Geol 48(3–4):245–251

Skoczylas N (2012) Laboratory study of the phenomenon of methane and coal outburst. Int J Rock Mech Min Sci 55:102–107

Skoczylas N (2014) Estimating gas and rock outburst risk on the basis of knowledge and experience—the expert system based on fuzzy logic. Arch Min Sci 59(1):41–52

Skoczylas N, Wierzbicki M (2014) Evaluation and management of the gas and rock outburst hazard in the light of international legal regulations. Arch Min Sci 59(4):1119–1129

Sobczyk J (2014) A comparison of the influence of adsorbed gases on gas stresses leading to coal and gas outburst. Fuel 115:288–294

Szlązak N, Korzec M (2016) Method for determining the coalbed methane content with determination the uncertainty of measurements. Arch Min Sci 61(2):443–456

Tian S, Jiang C, Xu L, Yang D, Tang J, Chen Y, Li X (2016) A study of the principles and methods of quick validation of the outburst-prevention effect in the process of coal uncovering. J Nat Gas Sci Eng 30:276–283

Topolnicki J, Wierzbicki M, Skoczylas N (2004) Rock and gas outbursts-laboratory tests and in-shaft measurements. Arch Min Sci 49(1):99–116

Wang S, Elsworth D, Liu J (2013) Mechanical behavior of methane infiltrated coal: the roles of gas desorption, stress level and loading rate. Rock Mech Rock Eng 46(5):945–958

Wierzbicki M, Młynarczuk M (2013) Structural aspects of gas and dolomite outburst in Rudna copper mine. Int J Rock Mech Min Sci 57:113–118

Wierzbicki M, Skoczylas N (2014) The outburst risk as a function of the methane capacity and firmness of a coal seam. Arch Min Sci 59(4):1023–1031

Xue S, Yuan L, Wang Y, Xie J (2014) Numerical analyses of the major parameters affecting the initiation of outbursts of coal and gas. Rock Mech Rock Eng 47(4):1505–1510

Acknowledgements

The present work was financed from the resources of the National Centre for Research and Development in Poland, as part of the project entitled “An innovative support system for gas hazard evaluation in copper ore mine” (Project No.: LIDER/003/408/L-4/12/NCBR/2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kudasik, M., Skoczylas, N. Balancing the amount and composition of gas contained in the pore space of cupriferous rocks. Environ Earth Sci 77, 135 (2018). https://doi.org/10.1007/s12665-018-7331-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-018-7331-8