Abstract

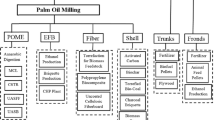

Palm kernel shell (PKS) is a by-product in palm oil milling during the extraction of crude palm oil from fresh fruit bunches. PKS is a promising solid fuel to replace coal with its high calorific value. As Japan is moving towards renewable power to reduce carbon dioxide emissions, importing biomass as fuel sources is trending. In the past decade, PKS has been imported extensively into Japan for biomass-power generation, replacing fossil fuels under the feed-in tariff. PKS is easiest to utilize in existing power plants from an economic perspective reducing the cost for energy transition. However, the environmental impact of transporting such biomass across long distances have not been systematically assessed. Therefore, this work presents a life cycle assessment (LCA) of power generation with PKS in Japan. The LCA study covers land conversion of palm cultivation in Malaysia to biomass power generation in Japan. Factors considered include greenhouse gas (GHG) emissions, eutrophication and water footprint. Eight Malaysian scenarios were analyzed, based on different boiler fuel applications in the palm oil mill. In addition, eight Japanese scenarios were also considered, based on imported PKS-dominant and local woodchip-dominant power generation. This work noted the significant effect of land use change on GHG emission. Based on results, imported PKS-dominant power generation in Japan is environmentally favorable than local woodchip-dominant power generation with careful selection of the biomass mix and power plant scale. PKS-based power generation contributes low GHG emissions which superior to fossil-based (coal, thermal oil, natural gas) power in Japan.

Graphical Abstract

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article and its supplementary information file.

Code Availability

Not applicable.

Abbreviations

- α:

-

Leaching run-off fraction

- AGB:

-

Aboveground biomass

- BGB:

-

Belowground biomass

- C act :

-

Actual pollutant concentration of intake water

- C effl :

-

Pollutant concentration in effluent

- C max :

-

Maximum acceptable pollutant concentration

- C nat :

-

Natural concentration of pollutant

- COD:

-

Chemical oxygen demand

- CPO:

-

Crude palm oil

- DOM:

-

Dead organic matter

- EFB:

-

Empty fruit bunch

- Effl :

-

Effluent

- ET :

-

Evapotranspiration

- FFB:

-

Fresh fruit bunch

- FIT:

-

Feed-in tariff

- GHG:

-

Greenhouse gas

- GWP:

-

Global warming potential

- HFO:

-

Heavy fuel oil

- JP:

-

Japan

- lgp :

-

Period of growing

- LPS:

-

Low-pressure steam

- LUC:

-

Land use change

- ML:

-

Malaysia

- PEFB:

-

Pressed EFB

- PKS:

-

Palm kernel shell

- POM:

-

Palm oil mill

- POME:

-

Palm oil mill effluent

- PPF:

-

Pressed palm fiber

- t:

-

Metric ton

- t-CO2 eq:

-

Ton of carbon dioxide equivalent emission

- TP:

-

Total phosphorus

- WF:

-

Water footprint

- wt%:

-

Percentage by weight

- Y :

-

Crop yield

- yr:

-

Year

- ΔC:

-

Carbon stock change in ton carbon per year

References

IEA International Energy Agency: SDG7: data and projections, flagship report—October 2020. https://www.iea.org/reports/sdg7-data-and-projections

IEA International Energy Agency: World energy model-sustainable development scenario, report—November 2019. https://www.iea.org/reports/world-energy-model/sustainable-development-scenario

IEA International Energy Agency: Renewables. https://www.iea.org/fuels-and-technologies/renewables

Agency for Natural Resources and Energy: General Resources and Energy Investigation Committee, Subcommittee on Basic Policy (38th meeting). https://www.enecho.meti.go.jp/committee/council/basic_policy_subcommittee/038/

Ministry of Economy, Trade and Industry: METI, 2020. Japan’s Energy 2019. Agency for Natural Resources and Energy, Japan. March 2020. https://www.enecho.meti.go.jp/en/category/brochures/pdf/japan_energy_2019.pdf

Ministry of Economy, Trade and Industry: METI, 2017. Japan’s Energy 2017. Agency for Natural Resources and Energy, Japan. December 2017. https://www.enecho.meti.go.jp/en/category/brochures/pdf/japan_energy_2017.pdf

Kimura, K.: Feed-in Tariffs in Japan: Five Years of Achievements and Future Challenges. Renewable Energy Institute, Tokyo (2017)

Malaysian Palm Oil Board (MPOB): Production of crude palm oil January–December. http://bepi.mpob.gov.my/index.php/en/production/production-2019/production-of-crude-oil-palm-2019.html

Embrandiri, A., Ibrahim, M.H., Singh, R.P.: Palm oil mill wastes utilization; Sustainability in the Malaysian context. Int. J. Sci. Res. Publ. 3, 1–7 (2013)

Kasivisvanathan, H., Ng, R.T.L., Tay, D.H.S., Ng, D.K.S.: Fuzzy optimisation for retrofitting a palm oil mill into a sustainable palm oil-based integrated biorefinery. Chem. Eng. J. (2012). https://doi.org/10.1016/j.cej.2012.05.113

Tsai, W.T.: Benefit analysis and regulatory actions for imported palm kernel shell as an environment-friendly energy source in Taiwan. Resources (2019). https://doi.org/10.3390/resources8010008

Mori energy. http://www.mori-energy.jp/hatsuden1.html

Levinson, R.: The growing importance of PKS in the Japanese Biomass Market. http://biomassmagazine.com/articles/16690/the-growing-importance-of-pks-in-the-japanese-biomass-market (2020)

Strauss, W., Kusano, Y.: What happens if Japan requires sustainability credentials for palm kernel shell (PKS)? (2019). https://www.futuremetrics.info

Oosawa, K., Kanematsu, Y., Kikuchi, Y.: Forestry and wood industry. In: Energy Technology Roadmaps of Japan. Springer Japan, Tokyo (2016)

Japan Woody Bioenergy Association: Wood Biomass Energy Data Book 2018. https://www.jwba.or.jp

Yu, Z., Loisel, J., Brosseau, D.P., Beilman, D.W., Hunt, S.J.: Global peatland dynamics since the Last Glacial Maximum. Geophys. Res. Lett. (2010). https://doi.org/10.1029/2010GL043584

Miettinen, J., Shi, C., Liew, S.C.: Two decades of destruction in Southeast Asia’s peat swamp forests. Front. Ecol. Environ. (2012). https://doi.org/10.1890/100236

Malaysian Palm Oil Board (MPOB): Oil palm planted area. https://bepi.mpob.gov.my/index.php/en/?option=com_content&view=category&id=115

Ravindranath, N.H., Madelene, O.: Methods for estimating above-ground biomass. In: Carbon Inventory Methods Handbook for Greenhouse Gas Inventory, Carbon Mitigation and Roundwood Production Projects. Springer Netherlands, Dordrecht (2008)

Ravindranath, N.H., Madelene, O.: Methods for below-ground biomass. In: Carbon Inventory Methods Handbook for Greenhouse Gas Inventory, Carbon Mitigation and Roundwood Production Projects. Springer Netherlands, Dordrecht (2008)

Ravindranath, N.H., Madelene, O.: Methods for dead organic matter: deadwood and litter. In: Carbon Inventory Methods Handbook for Greenhouse Gas Inventory, Carbon Mitigation and Roundwood Production Projects. Springer Netherlands, Dordrecht (2008)

Aalde, H., Gonzalez, P., Gytarsky, M., Krug, T., Kurz, W.A., Lasco, R.D., Martino, D.L., McConkey, B.G., Ogle, S., Paustian, K., Raison, J., Ravindranath, N.H., Schoene, D., Smith, P., Somogyi, Z., van Amstel, A., Verchot, L.: Generic methodologies applicable to multiple land use categories. In: Eggleston, S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K. (eds.) 2006 IPCC Guidelines for National Greenhouse Gas Inventories. IGES, Hayama (2006)

Gunarso, P., Hartoyo, M.K., Agus, F., Killeen, T.J.: Oil palm and land use change in Indonesia, Malaysia and Papua New Guinea (2013)

Hashim, Z., Muhamad, H., Subramaniam, V., May, C.Y.: Water footprint: part 2—FFB production for oil palm planted in Malaysia. J. Oil Palm Res. 26, 282–291 (2014)

Palm Oil World: Malaysian Palm Oil Board (MPOB)—Official Palm Oil Information Source. http://www.palmoilworld.org/environment.html

Woittiez, L.S., van Wijk, M.T., Slingerland, M., van Noordwijk, M., Giller, K.E.: Yield gaps in oil palm: a quantitative review of contributing factors. Eur. J. Agron. (2017). https://doi.org/10.1016/j.eja.2016.11.002

Foong, S.Z.Y., Lam, Y.L., Andiappan, V., Foo, D.C.Y., Ng, D.K.S.: A systematic approach for the synthesis and optimization of palm oil milling processes. Ind. Eng. Chem. Res. (2018). https://doi.org/10.1021/acs.iecr.7b04788

Foong, S., Andiappan, V., Tan, R., Foo, D., Ng, D.: Hybrid approach for optimisation and analysis of palm oil mill. Processes (2019). https://doi.org/10.3390/pr7020100

Madaki, Y.S., Seng, L.: Palm oil mill effluent (POME) from Malaysia palm oil mills: waste or resource. Int. J. Sci. Environ. Technol. 6, 1138–1155 (2013)

Rupani, F.P., Singh, R.P., Ibrahim, M.H., Esa, N.: Review of current palm oil mill effluent treatment: vermicomposting as a sustainable practice. World Appl. Sci. J. 11, 70–81 (2010)

Gamaralalage, D., Sawai, O., Nunoura, T.: Degradation behavior of palm oil mill effluent in Fenton oxidation. J. Hazard. Mater. (2019). https://doi.org/10.1016/j.jhazmat.2018.07.023

Yacob, S., Ali Hassan, M., Shirai, Y., Wakisaka, M., Subash, S.: Baseline study of methane emission from anaerobic ponds of palm oil mill effluent treatment. Sci. Total Environ. (2006). https://doi.org/10.1016/j.scitotenv.2005.07.003

Khalid, A.R., Mustafa, W.A.W.: External benefits of environmental regulation: resource recovery and the utilisation of effluents. Environmentalist (1992). https://doi.org/10.1007/BF01267698

Ma, A.N., Ong, A.S.H.: Pollution control in palm oil mills in Malaysia. J. Am. Oil Chem. Soc. 62, 261–266 (1985)

Harsono, S.S., Grundmann, P., Soebronto, S.: Anaerobic treatment of palm oil mill effluents: potential contribution to net energy yield and reduction of greenhouse gas emissions from biodiesel production. J. Clean. Prod. (2014). https://doi.org/10.1016/j.jclepro.2013.07.056

Loh, S.K., Lai, M.E., Muzzammil, N., Choo, W.S., Zhang, Z.: Zero discharge treatment technology of palm oil mill effluent. J. Oil Palm Res. 25, 273–281 (2013)

Sari, Y.W., Listiani, E., Putri, S.Y., Abidin, Z.: Prospective of eggshell nanocalcium in improving biogas production from palm oil mill effluent. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-019-00786-8

Choong, Y.Y., Chou, K.W., Norli, I.: Strategies for improving biogas production of palm oil mill effluent (POME) anaerobic digestion: a critical review. Renew. Sustain. Energy Rev. (2018). https://doi.org/10.1016/j.rser.2017.10.036

Lim, C., Biswas, W.K.: Sustainability implications of the incorporation of a biogas trapping system into a conventional crude palm oil supply chain. Sustainability (2019). https://doi.org/10.3390/su11030792

Wilfart, A., Gac, A., Salaün, Y., Aubin, J., Espagnol, S.: Allocation in the LCA of meat products: is agreement possible? Clean. Environ. Syst. (2021). https://doi.org/10.1016/j.cesys.2021.100028

Nambu, Y., Ikaga, T., Hondo, H., Kobayashi, K., Tsunetsugu, Y.: Developing a LCA Database of wood materials. AIJ J. Technol. Des. (2012). https://doi.org/10.3130/aijt.18.269

Takanashi, H., Oobayashi, K., Sagata, T., Teraoka, Y., Kai, T., Tsutsui, T., et al.: Unit requirements and formulas for estimating wood pellet cost and carbon dioxide emission in its utilization processes. Kankyou Kagaku Kaishi (Japan) 22, 241–246 (2009)

Hamzah, N., Tokimatsu, K., Yoshikawa, K.: Solid fuel from oil palm biomass residues and municipal solid waste by hydrothermal treatment for electrical power generation in Malaysia: a review. Sustainability (2019). https://doi.org/10.3390/su11041060

Hanafi, N.H., Hassim, M.H., Yusuf, M.R.M.: Emission factor establishment for palm oil mill boiler. Jurnal Teknologi (2016). https://doi.org/10.11113/jt.v78.9573

Dam, J.E.G.V., Elbersen, H.W.: Palm oil production for oil and biomass: the solution for sustainable oil production and certifiably sustainable biomass production. In: Kuiper, L. (ed.) Quick-Scans on Upstream Biomass: Yearbook 2004 and 2005, pp. 105–115 (2006)

Ng, D.K., Ng, R.T.: Applications of process system engineering in palm-based biomass processing industry. Curr. Opin. Chem. Eng. (2013). https://doi.org/10.1016/j.coche.2013.09.005

Onoja, E., Chandren, S., Abdul Razak, F.I., Mahat, N.A., Wahab, R.A.: Oil palm (Elaeis guineensis) biomass in Malaysia: the present and future prospects. Waste Biomass Valoriz. (2019). https://doi.org/10.1007/s12649-018-0258-1

Myhre, G., Shindell, D., Bréon, F.M., Collins, W., Fuglestvedt, J., Huang, J., Koch, D., Lamarque, J.F., Lee, D., Mendoza, B., Nakajima, T., Robock, A., Stephens, G., Takemura, T., Zhang, H.: Anthropogenic and natural radiative forcing. In: Stocker, T.F., Qin, D., Plattner, G.K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M. (eds.) Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, New York (2014)

Hoekstra, A.Y., Chapagain, A.K., Aldaya, M.M., Mokonnen, M.M.: The Water Footprint Assessment Manual—Setting the Global Standard. Earthscan, London (2011)

Ecoinvent database. https://www.ecoinvent.org

National Institute of Advanced Industrial Science and Technology, S. and S.R.D. and S. and L.R.G.J.: IDEA database: Environmental Management Association for Industry, version 2.2. (2018)

Harenda, K.M., Lamentowicz, M., Samson, M., Chojnicki, B.H.: The role of peatlands and their carbon storage function in the context of climate change. In: Zielinski T., Sagan I., Surosz W. (eds) Interdisciplinary Approaches for Sustainable Development Goals. GeoPlanet: Earth and Planetary Sciences. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-71788-3_12

Hirano, T., Segah, H., Kusin, K., Limin, S., Takahashi, H., Osaki, M.: Effects of disturbances on the carbon balance of tropical peat swamp forests. Glob. Change Biol. (2012). https://doi.org/10.1111/j.1365-2486.2012.02793.x

Rieley, J.O., Sieffermann, R.G., Page, S.E.: The origin, development, present status and importance of the lowland peat swamp forests of Borneo. Suo 43, 241–244 (1993)

Qiu, C., Ciais, P., Zhu, D., Guenet, B., Peng, S., Petrescu, A.M.R., Lauerwald, R., Makowski, D., Gallego-Sala, A.V., Charman, D.J., Brewer, S.C.: Large historical carbon emissions from cultivated northern peatlands. Sci. Adv. (2021). https://doi.org/10.1126/sciadv.abf1332

Pardon, L., Bessou, C., Nelson, P.N., Dubos, B., Ollivier, J., Marichal, R., Caliman, J.-P., Gabrielle, B.: Key unknowns in nitrogen budget for oil palm plantations. A review. Agron. Sustain. Dev. (2016). https://doi.org/10.1007/s13593-016-0353-2

Loh, S.K.: The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. (2017). https://doi.org/10.1016/j.enconman.2016.08.081

EFPC: The Federation of Electric Power Companies of Japan. https://www.fepc.or.jp/english/energy_electricity/location/thermal/

Climate Action Tracker: Japan’s coal power policy reflects the country’s highly insufficient level of ambition to avoid the climate crisis. Published 2020/07/07. https://climateactiontracker.org/press/japans-coal-power-policy-reflects-the-countrys-highlyinsufficient-level-of-ambition-to-avoid-the-climate-crisis/

Ministry of Natural Resources and Environment of Malaysia: Environmental requirements: a guide for investors, 11th edition. Putrajaya, Malaysia (2010)

Goh, K.L.: Fertilizer recommendation systems for oil palm: estimating the fertilizer rates. In: Soon, C.P., Pau, T.Y. (eds.) Proceedings of MOSTA Best Practices Workshops: Agronomy and Crop Management, Malaysia, pp. 235–268 (2005)

Huijbregts, M.A.J., Steinmann, Z.J.N., Elshout, P.M.F., Stam, G., Verones, F., Vieira, M.D.M., Hollander, A., Zijp, M., van Zelm, R.: ReCiPe 2016—a harmonized life cycle impact assessment method at midpoint and endpoint level report I: characterization (2016)

Estoque, R.C., Ooba, M., Avitabile, V., Hijioka, Y., DasGupta, R., Togawa, T., Murayama, Y.: The future of Southeast Asia’s forests. Nat. Commun. (2019). https://doi.org/10.1038/s41467-019-09646-4

Stibig, H.J., Achard, F., Carboni, S., Rasi, R., Miettinen, J.: Change in tropical forest cover of Southeast Asia from 1990 to 2010. Biogeosciences 11, 247–258 (2014)

FAO Food and Agriculture Organization of the United Nations: Global forest resource assessment 2020-report—Malaysia, Rome (2020)

Wicke, B., Dornburg, V., Junginger, M., Faaij, A.: Different palm oil production systems for energy purposes and their greenhouse gas implications. Biomass Bioenergy (2008). https://doi.org/10.1016/j.biombioe.2008.04.001

Mehmood, M.A., Ibrahim, M., Rashid, U., Nawaz, M., Ali, S., Hussain, A., Gull, M.: Biomass production for bioenergy using marginal lands. Sustain. Prod. Consum. (2017). https://doi.org/10.1016/j.spc.2016.08.003

Rajakal, J.P., Ng, D.K.S., Tan, R.R., Andiappan, V., Wan, Y.K.: A mathematical optimisation model for analysis of minimal cropland expansion in agro value chains. Sustain. Prod. Consum. (2019). https://doi.org/10.1016/j.spc.2019.06.004

Foo, D.C.Y., Aziz, A.M.K.: Green Technologies for the Oil Palm Industry. Springer Singapore, Singapore (2019)

Gallego, L.J., Cardona, S., Martínez, E., Rios, L.A.: Valorization of palm-oil residues: integrated production of a good quality bio-coal and electricity via torrefaction. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-018-0459-7

Misnon, I.I., Zain, N.K.M., Jose, R.: Conversion of oil palm kernel shell biomass to activated carbon for supercapacitor electrode application. Waste Biomass Valoriz. (2019). https://doi.org/10.1007/s12649-018-0196-y

Loh, S.K., Lai, M.E., Ngatiman, M.: Vegetative growth enhancement of organic fertilizer from anaerobically-treated palm oil mill effluent (POME) supplemented with chicken manure in food-energy-water nexus challenge. Food Bioprod. Process. 117, 95–104 (2019). https://doi.org/10.1016/j.fbp.2019.06.016

Hau, L.J., Shamsuddin, R., May, A.K.A., Saenong, A., Lazim, A.M., Narasimha, M., Low, A.: Mixed composting of palm oil empty fruit bunch (EFB) and palm oil mill effluent (POME) with various organics: an analysis on final macronutrient content and physical properties. Waste Biomass Valoriz. (2020). https://doi.org/10.1007/s12649-020-00993-8

Kikuchi, Y., Hirao, M.: Risk classification and identification for chemicals management in process design. J. Chem. Eng. Jpn. (2013). https://doi.org/10.1252/jcej.12we281

Nakatani, J., Fujii, M., Moriguchi, Y., Hirao, M.: Life-cycle assessment of domestic and transboundary recycling of post-consumer PET bottles. Int. J. Life Cycle Assess. (2010). https://doi.org/10.1007/s11367-010-0189-y

Kikuchi, Y., Nakai, M., Kanematsu, Y., Oosawa, K., Okubo, T., Oshita, Y., Fukushima, Y.: Application of technology assessments to co-learning for regional transformation: a case study of biomass energy systems in Tanegashima. Sustain. Sci. (2020). https://doi.org/10.1007/s11625-020-00801-1

Kikuchi, Y., Kanematsu, Y., Ugo, M., Hamada, Y., Okubo, T.: Industrial symbiosis centered on a regional cogeneration power plant utilizing available local resources: a case study of Tanegashima. J. Ind. Ecol. (2016). https://doi.org/10.1111/jiec.12347

Kanematsu, Y., Oosawa, K., Okubo, T., Kikuchi, Y.: Designing the scale of a woody biomass CHP considering local forestry reformation: a case study of Tanegashima, Japan. Appl. Energy (2017). https://doi.org/10.1016/j.apenergy.2017.04.021

Imamura, E., Iuchi, M., Bando, S.: Comprehensive assessment of life cycle CO2 emissions from power generation technologies in Japan, Report No. Y06 (2016)

Funding

Part of this study was financially supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI (Young Scientists A) [Grant Number 16H06126], and the Environment Research and Technology Development Fund [Grant Number 2-1910]. Activities of the Presidential Endowed Chair for “Platinum Society” at the University of Tokyo are supported by the KAITEKI Institute Incorporated, Mitsui Fudosan Corporation, Shin-Etsu Chemical Co., ORIX Corporation, Sekisui House, Ltd., the East Japan Railway Company, and Toyota Tsusho Corporation.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript. Conceptualization: Disni Gamaralalage, Yuichiro Kanematsu, Yasunori Kikuchi, Denny Ng. Methodology: Disni Gamaralalage, Yuichiro Kanematsu, Yasunori Kikuchi. Formal analysis and investigation: Disni Gamaralalage, Yuichiro Kanematsu. Writing—original draft preparation: Disni Gamaralalage, Yasunori Kikuchi. Writing—review and editing: Disni Gamaralalage, Dominic Foo, Viknesh Andiappan, Denny Ng, Yuichiro Kanematsu, Yasunori Kikuchi. Funding acquisition: Yasunori Kikuchi. Resources: Viknesh Andiappan, Denny Ng, Yasunori Kikuchi, Steve Foong. Supervision: Yasunori Kikuchi.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Research Involving Humans and/or Animals Participants

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gamaralalage, D., Kanematsu, Y., Ng, D.K.S. et al. Life Cycle Assessment of International Biomass Utilization: A Case Study of Malaysian Palm Kernel Shells for Biomass Power Generation in Japan. Waste Biomass Valor 13, 2717–2733 (2022). https://doi.org/10.1007/s12649-021-01643-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01643-3