Abstract

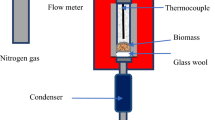

Energy valorization of empty fruit bunches (EFB), via torrefaction, was investigated to stablish the best process conditions and the energy balance of an integrated plant. Differential scanning calorimetry was used, for the first time, as a new and more accurate method to determine the heat involved in the torrefaction process. This technique showed that the torrefaction of EFB is an endothermal process. A new response variable energy gain (EG) was introduced as an alternative to the customarily used variable energy yield (EY). EG was definitely a better response variable because it makes a compromise between a high mass yield and a high heating values of the solid product. On the contrary, EY has a very strong and direct (lineal) correlation with the mass yield that overshadows the effect of the heating value. Results show that torrefaction is a promising technology for the sustainable valorization of EFB because it solves the disposal problem and gives a solid and renewable biofuel that can replace coal. Besides, an important amount of electricity can be co-produced. Energy balances showed that energy self-sufficiency can be achieved by tuning the torrefaction conditions as to obtain a gaseous by-product that is used as fuel to provide the energy required in the drying and torrefaction stages. Processing 100 ton/day of EFB (dry basis), at 300 °C and 60 min, produces 37 ton/day of bio-coal (similar to sub-bituminous coal) and 0.36 MW electricity that can be exported because the process is energy self- sufficient.

Similar content being viewed by others

Abbreviations

- EFB:

-

Oil palm empty fruit bunches

- KS:

-

Kernel shell

- MF:

-

Mesocarp fiber

- FFB:

-

Oil palm fresh fruit bunches

- MY:

-

Mass yield

- EY:

-

Energy yield

- EG:

-

Energy gain

- Fe:

-

Free of extractives

References

Castiblanco, C., Etter, A., Aide, T.M.: Oil palm plantations in Colombia: a model of future expansion. Environ. Sci. Policy 27, 172–183 (2013). https://doi.org/10.1016/j.envsci.2013.01.003

Indexmundi: Palm oil production by country. http://www.indexmundi.com/agriculture/?commodity=palm-oil. Accessed 2 Feb 2018

Fedepalma: Evolución histórica anual de Fruto Procesado en Colombia. http://sispa.fedepalma.org/sispaweb/default.aspx?Control=Pages/produccion. Accessed 2 Feb 2018

Ramírez, N., Arévalo, A., Garcia-Nunez, J.A.: Inventario de la biomasa disponible en plantas de beneficio para su aprovechamiento y caracterización fisicoquímica de la tusa en Colombia. Palmas 36, 41–54 (2015)

Dominghetti, T.F., de Barros S., Soares Cleber Oliveira, A.T.M., Cancado, P.H.D.: Stomoxys calcitrans (Diptera: Muscidae) outbreaks: current situation and future outlook with emphasis on Brazil. Braz. J. Vet. Parasitol. 24, 387–395 (2015). https://doi.org/10.1590/S1984-29612015079

Basu, P.: Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory. Elsevier Inc., London (2013)

Sabil, K.M., Aziz, M.a., Lal, B., Uemura, Y.: Effects of torrefaction on the physiochemical properties of oil palm empty fruit bunches, mesocarp fiber and kernel shell. Biomass Bioenergy 56, 351–360 (2013). https://doi.org/10.1016/j.biombioe.2013.05.015

Pimchuai, A., Dutta, A., Basu, P.: Torrefaction of agriculture residue to enhance combustible properties. Energy Fuels 24, 4638–4645 (2010). https://doi.org/10.1021/ef901168f

Ramírez, N.E., Silva, A.S., Garzón, E.M., Yáñez, E.E.: Caracterización y manejo de subproductos del beneficio del fruto de palma de aceite. Boletín Técnico No. 30 30, 1–46 (2011). https://doi.org/10.5897/AJB11.3582

Sukiran, M.A., Abnisa, F., Wan Daud, W.M.A., Abu Bakar, N., Loh, S.K.: A review of torrefaction of oil palm solid wastes for biofuel production. Energy Convers. Manag. 149, 101–120 (2017). https://doi.org/10.1016/j.enconman.2017.07.011

Nhuchhen, D., Basu, P., Acharya, B.: A comprehensive review on biomass torrefaction. Int. J. Renew. Energy Biofuels 2014, 1–56 (2014). https://doi.org/10.5171/2014.506376

Briceño, I., Valencia, J., Posso, M.: Potencial de generación de energía de la agroindustria de la palma de aceite en Colombia. PALMAS 36, 43–53 (2015)

Agar, D., Wihersaari, M.: Bio-coal, torrefied lignocellulosic resources—key properties for its use in co-firing with fossil coal—their status. Biomass Bioenergy 44, 107–111 (2012). https://doi.org/10.1016/j.biombioe.2012.05.004

Arteaga-Pérez, L.E., Segura, C., Bustamante-García, V., Cápiro, O.G., Jiménez, R.: Torrefaction of wood and bark from Eucalyptus globulus and Eucalyptus nitens: focus on volatile evolution vs feasible temperatures. Energy 93, 1731–1741 (2015). https://doi.org/10.1016/j.energy.2015.10.007

Felfli, F.F., Luengo, C.A., Suárez, J.A., Beatón, P.A.: Wood briquette torrefaction. Energy Sustain. Dev. 9, 19–22 (2005). https://doi.org/10.1016/S0973-0826(08)60519-0

Prins, M.J., Ptasinski, K.J., Janssen, F.J.J.G.: Torrefaction of wood. Part 1. Weight loss kinetics. J. Anal. Appl. Pyrolysis 77, 28–34 (2006). https://doi.org/10.1016/j.jaap.2006.01.002

Nam, S.B., Park, Y.S., Kim, D.J., Gu, J.H.: Torrefaction reaction characteristic of various biomass waste on pilot scale of torrefaction reaction system. Procedia Environ. Sci. 35, 890–894 (2016). https://doi.org/10.1016/j.proenv.2016.07.044

Bridgeman, T.G., Jones, J.M., Shield, I., Williams, P.T.: Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 87, 844–856 (2008). https://doi.org/10.1016/j.fuel.2007.05.041

Aziz, M., Sabil, K., Uemura, Y., Ismail, L.: A study on torrefaction of oil palm biomass. J. Appl. Sci. 12, 1130–1135 (2012). https://doi.org/10.3923/jas.2012.1130.1135

Bergman, P., Veringa, H.J.: Combined torrefaction and pelletisation, The TOP process. Report ECN-C–05–073 (2005)

Yan, W., Hastings, J.T., Acharjee, T.C., Coronella, C.J., Vásquez, V.R.: Mass and energy balances of wet torrefaction of lignocellulosic biomass. Energy Fuels 24, 4738–4742 (2010). https://doi.org/10.1021/ef901273n

Nanou, P., Carbo, M.C., Kiel, J.H.A.: Detailed mapping of the mass and energy balance of a continuous biomass torrefaction plant. Biomass Bioenergy 89, 67–77 (2015). https://doi.org/10.1016/j.biombioe.2016.02.012

Bates, R.B., Ghoniem, A.F.: Biomass torrefaction: modeling of reaction thermochemistry. Bioresour. Technol. 134, 331–340 (2013). https://doi.org/10.1016/j.biortech.2013.01.158

Granados, D.A., Velasquez, H.I., Chejne, F.: Energetic and exergetic evaluation of residual biomass in a torrefaction process. Energy 74, 181–189 (2014). https://doi.org/10.1016/j.energy.2014.05.046

Ohliger, A., Förster, M., Kneer, R.: Torrefaction of beechwood: a parametric study including heat of reaction and grindability. Fuel 104, 607–613 (2013). https://doi.org/10.1016/j.fuel.2012.06.112

Rath, J., Wolfinger, M.G., Steiner, G., Krammer, G., Barontini, F., Cozzani, V.: Heat of wood pyrolysis. Fuel 82, 81–91 (2003). https://doi.org/10.1016/S0016-2361(02)00138-2

Sulaiman, M.H., Uemura, Y., Azizan, M.T.: Torrefaction of empty fruit bunches in inert condition at various temperature and time. Procedia Eng. 148, 573–579 (2016). https://doi.org/10.1016/j.proeng.2016.06.514

Loh, S.K.: The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. 141, 285–298 (2017). https://doi.org/10.1016/j.enconman.2016.08.081

Uemura, Y., Sellappah, V., Hoai Thanh, T., Hassan, S., Tanoue, K.: Torrefaction of empty fruit bunches under biomass combustion gas atmosphere. Bioresour. Technol. (2017). https://doi.org/10.1016/j.biortech.2017.06.057

Chin, K.L., H’ng, P.S., Go, W.Z., Wong, W.Z., Lim, T.W., Maminski, M., Paridah, M.T., Luqman, A.C.: Optimization of torrefaction conditions for high energy density solid biofuel from oil palm biomass and fast growing species available in Malaysia. Ind. Crops Prod. 49, 768–774 (2013). https://doi.org/10.1016/j.indcrop.2013.06.007

Uemura, Y., Omar, W.N., Tsutsui, T., Yusup, S.B.: Torrefaction of oil palm wastes. Fuel. 90, 2585–2591 (2011). https://doi.org/10.1016/j.fuel.2011.03.021

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D.: Determination of ash in biomass laboratory analytical procedure (LAP) issue date: 7/17/2005. p. 14 (2008)

Sluiter, A., Hames, B., Ruiz, R.O., Scarlata, C., Sluiter, J., Templeton, D., Crocker D.: Determination of Structural Carbohydrates and Lignin in Biomass. Golden, National Renewable Energy Laboratory (2004)

Ghose, T.K.: Measurement of cellulase activities. Pure Appl. Chem. 59, 257–268 (1987). https://doi.org/10.1351/pac198759020257

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426 (1959)

Gallego, L.J., Escobar, A., Peñuela, M., Peña, J.D., Rios, L.A.: King grass: a promising material for the production of second-generation butanol. Fuel 143, 399–403 (2015). https://doi.org/10.1016/j.fuel.2014.11.077

Bridgeman, T.G., Jones, J.M.: Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 87, 844–856 (2008). https://doi.org/10.1016/j.fuel.2007.05.041

Nyakuma, B., Ahmad, A., Johari, A., Abdullah, T.A., Oladokun, O.: Torrefaction of pelletized oil palm empty fruit bunches. In: The 21st international symposium on alcohol fuels—21st ISAF. pp. 15–19 (2015)

Smith, A.M., Ross, A.B.: Production of bio-coal, bio-methane and fertilizer from seaweed via hydrothermal carbonisation. Algal Res. 16, 1–11 (2016). https://doi.org/10.1016/j.algal.2016.02.026

Li, J., Brzdekiewicz, A., Yang, W., Blasiak, W.: Co-firing based on biomass torrefaction in a pulverized coal boiler with aim of 100% fuel switching. Appl. Energy. 99, 344–354 (2012). https://doi.org/10.1016/j.apenergy.2012.05.046

Chang, S., Zhao, Z., Zheng, A., He, F., Huang, Z., Li, H.: Characterization of products from torrefaction of sprucewood and bagasse in an auger reactor. Energy Fuels 26, 7009–7017 (2012). https://doi.org/10.1021/ef301048a

Chen, W.H., Liu, S.H., Juang, T.T., Tsai, C.M., Zhuang, Y.Q.: Characterization of solid and liquid products from bamboo torrefaction. Appl. Energy 160, 829–835 (2015). https://doi.org/10.1016/j.apenergy.2015.03.022

Arteaga-Pérez, L.E., Grandón, H., Flores, M., Segura, C., Kelley, S.S.: Steam torrefaction of Eucalyptus globulus for producing black pellets: a pilot-scale experience. Bioresour. Technol. 238, 194–204 (2017). https://doi.org/10.1016/j.biortech.2017.04.037

Prins, M.J., Ptasinski, K.J., Janssen, F.J.J.G.: Torrefaction of wood. Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 77, 35–40 (2006). https://doi.org/10.1016/j.jaap.2006.01.001

Faleeva, J.M., Sinelshchikov, V.A., Sytchev, G.A., Zaichenko, V.M.: Exothermic effect during torrefaction. J. Phys. Conf. Ser. (2018). https://doi.org/10.1088/1742-6596/946/1/012033

European Biomass Association (AEBIOM): Report on conversion efficiency of biomass, version #2. (2015). http://www.basisbioenergy.eu/fileadmin/BASIS/D3.5_Report_on_conversion_efficiency_of_biomass.pdf. Accessed 10 Feb 2018

Shankar Tumuluru, J., Sokhansanj, S., Hess, J.R., Wright, C.T., Boardman, R.D.: REVIEW: a review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 7, 384–401 (2011). https://doi.org/10.1089/ind.2011.7.384

Acknowledgements

The authors thank the financial support provided by “Departamento Administrativo de Ciencia, Tecnología e Innovación-Colciencias”, “Patrimonio Autónomo Fondo Nacional de Financiamiento para la Ciencia, la Tecnología y la Innovación, Francisco José de Caldas”, “Cementos Argos S.A.” and “Comité para el Desarrollo de la Investigación-CODI, Universidad de Antioquia”.

Author information

Authors and Affiliations

Contributions

LJG, SC, EM, LAR contributed equally in both the experiments and writing of this manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Gallego, L.J., Cardona, S., Martínez, E. et al. Valorization of Palm-Oil Residues: Integrated Production of a Good Quality Bio-coal and Electricity via Torrefaction. Waste Biomass Valor 11, 2273–2284 (2020). https://doi.org/10.1007/s12649-018-0459-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0459-7