Abstract

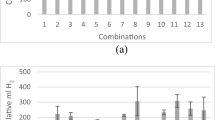

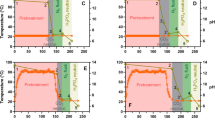

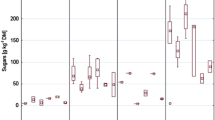

The Colombian agroindustry has high diversity and availability of residual biomass year after year. These wastes are susceptible to being recovered through biological processes to reducing production costs of some raw materials and the pollutant load to the environment. This study identified the value-added by-products during the use of pig manure (PM), coffee mucilage (CM), and cocoa (CoM) through a dark fermentation process in a battery of batch reactors (200 ml bottles). The organic load (2, 5, and 8 gCOD/l), the C/N ratio (25, 35, and 45), and the ratio of the CM: CoM (3:1, 1:1, and 1:3) were evaluated. The highest hydrogen production yield of 271.3 ml H2/gCOD was associated with the experimental conditions of mixture 2 (2 gCOD/l, 35 C/N ratio, and CM: CoM 1: 3). Acetate, propionate, butyrate, and lactate fermentations were associated with the metabolic pathways of the process and participated in the soluble COD with 29, 12, 46, and 13%, respectively. It was identified that the acetate-butyrate pathway was the main metabolic pathway, and the acetate/butyrate ratio was in the range of 1:1–5.9:1. The microbial population found in the co-digestion processes worked on was dominated by the genera Clostridium, Bacillus, and Tisierella. The complex substrates used in this co-digestion process can produce value-added by-products and energy in a range of theoretical stoichiometry.

Graphic Abstract

Similar content being viewed by others

References

Yin, J., Yu, X., Wang, K., Shen, D.: Acidogenic fermentation of the main substrates of food waste to produce volatile fatty acids. Int. J. Hydrog. Energy 41, 21713–21720 (2016). https://doi.org/10.1016/j.ijhydene.2016.07.094

Banerjee, J., Singh, R., Vijayaraghavan, R., MacFarlane, D., Patti, A.F., Arora, A.: Bioactives from fruit processing wastes: green approaches to valuable chemicals. Food Chem. 225, 10–22 (2017). https://doi.org/10.1016/j.foodchem.2016.12.093

Mohan, S.V., Nikhil, G.N., Chiranjeevi, P., Reddy, C.N., Rohit, M.V., Kumar, A.N., Sarkar, O.: Waste biorefinery models towards sustainable circular bioeconomy: critical review and future perspectives. Bioresour. Technol. 215, 2–12 (2016). https://doi.org/10.1016/j.biortech.2016.03.130

Kapdan, I.K., Kargi, F.: Bio-hydrogen production from waste materials. Enzyme Microb. Technol. 38, 569–582 (2006). https://doi.org/10.1016/j.enzmictec.2005.09.015

de Sá, L.R.V., Cammarota, M.C., de Oliveira, T.C., Oliveira, E.M.M., Matos, A., Ferreira-Leitão, V.S.: Pentoses, hexoses and glycerin as substrates for biohydrogen production: an approach for Brazilian biofuel integration. Int. J. Hydrog. Energy 38, 2986–2997 (2013). https://doi.org/10.1016/j.ijhydene.2012.12.103

Mohan, S.V., Mohanakrishna, G., Goud, R.K., Sarma, P.N.: Acidogenic fermentation of vegetable based market waste to harness biohydrogen with simultaneous stabilization. Bioresour. Technol. 100, 3061–3068 (2009). https://doi.org/10.1016/j.biortech.2008.12.059

Saady, N.M.C.: Homoacetogenesis during hydrogen production by mixed cultures dark fermentation: unresolved challenge. Int. J. Hydrog. Energy 38, 13172–13191 (2013). https://doi.org/10.1016/j.ijhydene.2013.07.122

Sawatdeenarunat, C., Nguyen, D., Surendra, K.C., Shrestha, S., Rajendran, K., Oechsner, H., Xie, L., Khanal, S.K.: Anaerobic biorefinery: current status, challenges, and opportunities. Bioresour. Technol. 215, 304–313 (2016). https://doi.org/10.1016/j.biortech.2016.03.074

Urbaniec, K., Bakker, R.R.: Biomass residues as raw material for dark hydrogen fermentation—a review. Int. J. Hydrog. Energy 40, 3648–3658 (2015). https://doi.org/10.1016/j.ijhydene.2015.01.073

Zhou, M., Yan, B., Wong, J.W.C., Zhang, Y.: Enhanced volatile fatty acids production from anaerobic fermentation of food waste: a mini-review focusing on acidogenic metabolic pathways. Bioresour. Technol. 248, 68–78 (2018). https://doi.org/10.1016/j.biortech.2017.06.121

Cieślik, B., Konieczka, P.: A review of phosphorus recovery methods at various steps of wastewater treatment and sewage sludge management. The concept of “no solid waste generation” and analytical methods. J. Clean. Prod. 142, 1728–1740 (2017). https://doi.org/10.1016/j.jclepro.2016.11.116

Fei, Q., Fu, R., Shang, L., Brigham, C.J., Chang, H.N.: Lipid production by microalgae Chlorella protothecoides with volatile fatty acids (VFAs) as carbon sources in heterotrophic cultivation and its economic assessment. Bioprocess Biosyst. Eng. 38, 691–700 (2015). https://doi.org/10.1007/s00449-014-1308-0

Harmsen, P.F.H., Hackmann, M.M., Bos, H.L.: Green building blocks for bio-based plastics. Biofuels Bioprod. Biorefining 8, 306–324 (2014). https://doi.org/10.1002/bbb.1468

Singhania, R.R., Patel, A.K., Christophe, G., Fontanille, P., Larroche, C.: Biological upgrading of volatile fatty acids, key intermediates for the valorization of biowaste through dark anaerobic fermentation. Bioresour. Technol. 145, 166–174 (2013). https://doi.org/10.1016/j.biortech.2012.12.137

Calt, E.A.: Products produced from organic waste using managed ecosystem fermentation. J. Sustain. Dev. 8, 43 (2015). https://doi.org/10.5539/jsd.v8n3p43

Soares, J.F., Confortin, T.C., Todero, I., Mayer, F.D., Mazutti, M.A.: Dark fermentative biohydrogen production from lignocellulosic biomass: technological challenges and future prospects. Renew. Sustain. Energy Rev. 117, (2020). https://doi.org/10.1016/j.rser.2019.109484

Oleskowicz-Popiel, P., Kádár, Z., Heiske, S., Klein-Marcuschamer, D., Simmons, B.A., Blanch, H.W., Schmidt, J.E.: Co-production of ethanol, biogas, protein fodder and natural fertilizer in organic farming—evaluation of a concept for a farm-scale biorefinery. Bioresour. Technol. 104, 440–446 (2012). https://doi.org/10.1016/j.biortech.2011.11.060

Shen, D., Yin, J., Yu, X., Wang, M., Long, Y., Shentu, J., Chen, T.: Acidogenic fermentation characteristics of different types of protein-rich substrates in food waste to produce volatile fatty acids. Bioresour. Technol. 227, 125–132 (2017). https://doi.org/10.1016/j.biortech.2016.12.048

Han, W., Wang, X., Ye, L., Huang, J., Tang, J., Li, Y., Ren, N.: Fermentative hydrogen production using wheat flour hydrolysate by mixed culture. Int. J. Hydrog. Energy 40, 4474–4480 (2015). https://doi.org/10.1016/j.ijhydene.2015.02.016

Khanal, S.K., Chen, W.-H., Li, L., Sung, S.: Biological hydrogen production: effects of pH and intermediate products. Int. J. Hydrog. Energy 29, 1123–1131 (2004). https://doi.org/10.1016/j.ijhydene.2003.11.002

Ye, J., Li, D., Sun, Y., Wang, G., Yuan, Z., Zhen, F., Wang, Y.: Improved biogas production from rice straw by co-digestion with kitchen waste and pig manure. Waste Manag. 33, 2653–2658 (2013). https://doi.org/10.1016/j.wasman.2013.05.014

Zhou, J., Zhang, R., Liu, F., Yong, X., Wu, X., Zheng, T., Jiang, M., Jia, H.: Biogas production and microbial community shift through neutral pH control during the anaerobic digestion of pig manure. Bioresour. Technol. 217, 44–49 (2016). https://doi.org/10.1016/j.biortech.2016.02.077

Dahiya, S., Sarkar, O., Swamy, Y.V., Mohan, S.V.: Acidogenic fermentation of food waste for volatile fatty acid production with co-generation of biohydrogen. Bioresour. Technol. 182, 103–113 (2015). https://doi.org/10.1016/j.biortech.2015.01.007

Liu, H., Wang, J., Liu, X., Fu, B., Chen, J., Yu, H.-Q.: Acidogenic fermentation of proteinaceous sewage sludge: effect of pH. Water Res. 46, 799–807 (2012). https://doi.org/10.1016/j.watres.2011.11.047

Khongkliang, P., Jehlee, A., Kongjan, P., Reungsang, A., O-Thong, S.: High efficient biohydrogen production from palm oil mill effluent by two-stage dark fermentation and microbial electrolysis under thermophilic condition. Int. J. Hydrog. Energy. 44, 31841–31852 (2019). https://doi.org/10.1016/j.ijhydene.2019.10.022

Martinez-Burgos, W.J., Sydney, E.B., de Paula, D.R., Medeiros, A.B.P., de Carvalho, J.C., Soccol, V.T., de Souza Vandenberghe, L.P., Woiciechowski, A.L., Soccol, C.R.: Biohydrogen production in cassava processing wastewater using microbial consortia: process optimization and kinetic analysis of the microbial community. Bioresour. Technol. 309, (2020). https://doi.org/10.1016/j.biortech.2020.123331

Guo, X.M., Trably, E., Latrille, E., Carrere, H., Steyer, J.-P.: Predictive and explicative models of fermentative hydrogen production from solid organic waste: role of butyrate and lactate pathways. Int. J. Hydrog. Energy 39, 7476–7485 (2014). https://doi.org/10.1016/j.ijhydene.2013.08.079

Lopez-Hidalgo, A.M., Alvarado-Cuevas, Z.D., De Leon-Rodriguez, A.: Biohydrogen production from mixtures of agro-industrial wastes: chemometric analysis, optimization and scaling up. Energy 159, 2–41 (2018). https://doi.org/10.1016/j.energy.2018.06.124

Montoya, A.C.V., da Silva Mazareli, R.C., Delforno, T.P., Centurion, V.B., Sakamoto, I.K., de Oliveira, V.M., Silva, E.L., Varesche, M.B.A.: Hydrogen, alcohols and volatile fatty acids from the co-digestion of coffee waste (coffee pulp, husk, and processing wastewater) by applying autochthonous microorganisms. Int. J. Hydrog. Energy 44, 21434–21450 (2019). https://doi.org/10.1016/j.ijhydene.2019.06.115

Hernández, M.A., Susa, M.R., Andres, Y.: Use of coffee mucilage as a new substrate for hydrogen production in anaerobic co-digestion with swine manure. Bioresour. Technol. 168, 112–118 (2014). https://doi.org/10.1016/j.biortech.2014.02.101

Tenca, A., Schievano, A., Perazzolo, F., Adani, F., Oberti, R.: Biohydrogen from thermophilic co-fermentation of swine manure with fruit and vegetable waste: maximizing stable production without pH control. Bioresour. Technol. 102, 8582–8588 (2011). https://doi.org/10.1016/j.biortech.2011.03.102

Ramsay, I.R., Pullammanappallil, P.C.: Protein degradation during anaerobic wastewater treatment: derivation of stoichiometry. Biodegradation 12, 247–257 (2001). https://doi.org/10.1023/A:1013116728817

Mäkinen, A.E., Nissilä, M.E., Puhakka, J.A.: Dark fermentative hydrogen production from xylose by a hot spring enrichment culture. Int. J. Hydrog. Energy 37, 12234–12240 (2012). https://doi.org/10.1016/j.ijhydene.2012.05.158

APHA: Standard Methods for the Examination of Water and Wastewater. APHA, Washington (2005)

Keegan, K.P., Glass, E.M., Meyer, F.: Microbial environmental genomics. Microb. Ecol. 53, 367–368 (2007). https://doi.org/10.1007/s00248-007-9214-5

Huson, D.H., Beier, S., Flade, I., Górska, A., El-Hadidi, M., Mitra, S., Ruscheweyh, H.J., Tappu, R.: MEGAN community edition—interactive exploration and analysis of large-scale microbiome sequencing data. PLoS Comput. Biol. 12, 1–12 (2016). https://doi.org/10.1371/journal.pcbi.1004957

Parks, D.H., Tyson, G.W., Hugenholtz, P., Beiko, R.G.: STAMP: statistical analysis of taxonomic and functional profiles. Bioinformatics 30, 3123–3124 (2014). https://doi.org/10.1093/bioinformatics/btu494

Marone, A., Ayala-Campos, O.R., Trably, E., Carmona-Martínez, A.A., Moscoviz, R., Latrille, E., Steyer, J.-P., Alcaraz-Gonzalez, V., Bernet, N.: Coupling dark fermentation and microbial electrolysis to enhance bio-hydrogen production from agro-industrial wastewaters and by-products in a bio-refinery framework. Int. J. Hydrog. Energy 42, 1609–1621 (2017). https://doi.org/10.1016/j.ijhydene.2016.09.166

Argun, H., Dao, S.: Hydrogen gas production from waste peach pulp by natural microflora. Waste Biomass Valoriz. 9, 2117–2124 (2018). https://doi.org/10.1007/s12649-017-9990-1

Crognale, S., Tonanzi, B., Valentino, F., Majone, M., Rossetti, S.: Microbiome dynamics and phaC synthase genes selected in a pilot plant producing polyhydroxyalkanoate from the organic fraction of urban waste. Sci. Total Environ. 689, 765–773 (2019)

Bolaji, I.O., Dionisi, D.: Acidogenic fermentation of vegetable and salad waste for chemicals production: effect of pH buffer and retention time. J. Environ. Chem. Eng. 5, 5933–5943 (2017)

Oceguera-Contreras, E., Aguilar-Juárez, O., Oseguera-Galindo, D., Macías-Barragán, J., Bolaños-Rosales, R., Mena-Enríquez, M., Arias-García, A., Montoya-Buelna, M., Graciano-Machuca, O., De León-Rodríguez, A.: Biohydrogen production by vermihumus-associated microorganisms using agro industrial wastes as substrate. Int. J. Hydrog. Energy. 44, 9856–9865 (2019). https://doi.org/10.1016/j.ijhydene.2018.10.236

Soltan, M., Elsamadony, M., Tawfik, A.: Biological hydrogen promotion via integrated fermentation of complex agro-industrial wastes. Appl. Energy 185, 929–938 (2017). https://doi.org/10.1016/j.apenergy.2016.10.002

Chatellard, L., Trably, E., Carrère, H.: The type of carbohydrates specifically selects microbial community structures and fermentation patterns. Bioresour. Technol. 221, 541–549 (2016). https://doi.org/10.1016/j.biortech.2016.09.084

Strazzera, G., Battista, F., Garcia, N.H., Frison, N., Bolzonella, D.: Volatile fatty acids production from food wastes for biorefinery platforms: a review. J. Environ. Manag. 226, 278–288 (2018). https://doi.org/10.1016/j.jenvman.2018.08.039

Yuan, H., Chen, Y., Zhang, H., Jiang, S., Zhou, Q., Gu, G.: Improved bioproduction of short-chain fatty acids (SCFAs) from excess sludge under alkaline conditions. Environ. Sci. Technol. 40, 2025–2029 (2006). https://doi.org/10.1021/es052252b

Kim, I.S., Hwang, M.H., Jang, N.J., Hyun, S.H., Lee, S.T.: Effect of low pH on the activity of hydrogen utilizing methanogen in bio-hydrogen process. Int. J. Hydrog. Energy 29, 1133–1140 (2004). https://doi.org/10.1016/j.ijhydene.2003.08.017

Mockaitis, G., Bruant, G., Guiot, S.R., Peixoto, G., Foresti, E., Zaiat, M.: Acidic and thermal pre-treatments for anaerobic digestion inoculum to improve hydrogen and volatile fatty acid production using xylose as the substrate. Renew. Energy 145, 1388–1398 (2020). https://doi.org/10.1016/j.renene.2019.06.134

Banu, J.R., Kavitha, S., Kannah, R.Y., Bhosale, R.R., Kumar, G.: Industrial wastewater to biohydrogen: possibilities towards successful biorefinery route. Bioresour. Technol. (2019). https://doi.org/10.1016/j.biortech.2019.122378

Cavinato, C., Da Ros, C., Pavan, P., Bolzonella, D.: Influence of temperature and hydraulic retention on the production of volatile fatty acids during anaerobic fermentation of cow manure and maize silage. Bioresour. Technol. 223, 59–64 (2017). https://doi.org/10.1016/j.biortech.2016.10.041

Kumar, G., Ponnusamy, V.K., Bhosale, R.R., Shobana, S., Yoon, J.-J., Bhatia, S.K., Banu, J.R., Kim, S.-H.: A review on the conversion of volatile fatty acids to polyhydroxyalkanoates using dark fermentative effluents from hydrogen production. Bioresour. Technol. 287, (2019). https://doi.org/10.1016/j.biortech.2019.121427

Chen, Y., Li, X., Zheng, X., Wang, D.: Enhancement of propionic acid fraction in volatile fatty acids produced from sludge fermentation by the use of food waste and Propionibacterium acidipropionici. Water Res. 47, 615–622 (2013). https://doi.org/10.1016/j.watres.2012.10.035

Li, X., Zhang, W., Ma, L., Lai, S., Zhao, S., Chen, Y., Liu, Y.: Improved production of propionic acid driven by hydrolyzed liquid containing high concentration of l-lactic acid from co-fermentation of food waste and sludge. Bioresour. Technol. 220, 523–529 (2016). https://doi.org/10.1016/j.biortech.2016.08.066

Liang, S., McDonald, A.G., Coats, E.R.: Lactic acid production with undefined mixed culture fermentation of potato peel waste. Waste Manag. 34, 2022–2027 (2014). https://doi.org/10.1016/j.wasman.2014.07.009

Shi, E., Li, J., Zhang, M.: Application of IWA Anaerobic Digestion Model No. 1 to simulate butyric acid, propionic acid, mixed acid, and ethanol type fermentative systems using a variable acidogenic stoichiometric approach. Water Res. 161, 242–250 (2019). https://doi.org/10.1016/j.watres.2019.05.094

Zhou, M., Zhou, J., Tan, M., Du, J., Yan, B., Wong, J.W.C., Zhang, Y.: Enhanced carboxylic acids production by decreasing hydrogen partial pressure during acidogenic fermentation of glucose. Bioresour. Technol. 245, 44–51 (2017). https://doi.org/10.1016/J.BIORTECH.2017.08.152

Tang, J., Wang, X.C., Hu, Y., Zhang, Y., Li, Y.: Effect of pH on lactic acid production from acidogenic fermentation of food waste with different types of inocula. Bioresour. Technol. 224, 544–552 (2017). https://doi.org/10.1016/j.biortech.2016.11.111

Hussain, A., Filiatrault, M., Guiot, S.R.: Acidogenic digestion of food waste in a thermophilic leach bed reactor: effect of pH and leachate recirculation rate on hydrolysis and volatile fatty acid production. Bioresour. Technol. 245, 1–9 (2017). https://doi.org/10.1016/j.biortech.2017.08.130

Feng, K., Li, H., Zheng, C.: Shifting product spectrum by pH adjustment during long-term continuous anaerobic fermentation of food waste. Bioresour. Technol. 270, 180–188 (2018). https://doi.org/10.1016/j.biortech.2018.09.035

Łukajtis, R., Hołowacz, I., Kucharska, K., Glinka, M., Rybarczyk, P., Przyjazny, A., Kamiński, M.: Hydrogen production from biomass using dark fermentation. Renew. Sustain. Energy Rev. 91, 665–694 (2018). https://doi.org/10.1016/J.RSER.2018.04.043

Akutsu, Y., Lee, D.-Y., Li, Y.-Y., Noike, T.: Hydrogen production potentials and fermentative characteristics of various substrates with different heat-pretreated natural microflora. Int. J. Hydrog. Energy 34, 5365–5372 (2009). https://doi.org/10.1016/j.ijhydene.2009.04.052

Quéméneur, M., Hamelin, J., Benomar, S., Guidici-Orticoni, M.-T., Latrille, E., Steyer, J.-P., Trably, E.: Changes in hydrogenase genetic diversity and proteomic patterns in mixed-culture dark fermentation of mono-, di- and tri-saccharides. Int. J. Hydrog. Energy 36, 11654–11665 (2011). https://doi.org/10.1016/j.ijhydene.2011.06.010

Cheng, J., Su, H., Zhou, J., Song, W., Cen, K.: Microwave-assisted alkali pretreatment of rice straw to promote enzymatic hydrolysis and hydrogen production in dark- and photo-fermentation. Int. J. Hydrog. Energy 36, 2093–2101 (2011). https://doi.org/10.1016/j.ijhydene.2010.11.021

Hu, B., Chen, S.: Pretreatment of methanogenic granules for immobilized hydrogen fermentation. Int. J. Hydrog. Energy 32, 3266–3273 (2007). https://doi.org/10.1016/j.ijhydene.2007.03.005

Sołowski, G., Shalaby, M.S., Abdallah, H., Shaban, A.M., Cenian, A.: Production of hydrogen from biomass and its separation using membrane technology. Renew. Sustain. Energy Rev. 82, 3152–3167 (2018). https://doi.org/10.1016/j.rser.2017.10.027

Ghimire, A., Frunzo, L., Pirozzi, F., Trably, E., Escudie, R., Lens, P.N.L., Esposito, G.: A review on dark fermentative biohydrogen production from organic biomass: process parameters and use of by-products. Appl. Energy 144, 73–95 (2015). https://doi.org/10.1016/j.apenergy.2015.01.045

Jiang, L., Fu, H., Yang, H.K., Xu, W., Wang, J., Yang, S.-T.: Butyric acid: applications and recent advances in its bioproduction. Biotechnol. Adv. 36, 2101–2117 (2018)

Chen, H., Meng, H., Nie, Z., Zhang, M.: Polyhydroxyalkanoate production from fermented volatile fatty acids: effect of pH and feeding regimes. Bioresour. Technol. 128, 533–538 (2013). https://doi.org/10.1016/j.biortech.2012.10.121

Mendez, D., Cabeza, I., Moreno, N., Riascos, C.: Mathematical modelling and scale-up of batch fermentation with burkholderia cepacia B27 using vegetal oil as carbon source to produce polyhydroxyalkanoates. Chem. Eng. Trans. 49, 277–282 (2016)

Bozell, J.J., Petersen, G.R.: Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem. 12, 539–554 (2010)

de Jong, E., Higson, A., Walsh, P., Wellisch, M.: Bio-based chemicals value added products from biorefineries, IEA Bioenergy. Task42 Biorefinery 34 (2012)

Choi, S., Song, C.W., Shin, J.H., Lee, S.Y.: Biorefineries for the production of top building block chemicals and their derivatives. Metab. Eng. 28, 223–239 (2015). https://doi.org/10.1016/j.ymben.2014.12.007

Acknowledgements

The authors acknowledge financial support from MinCiencias (Ministry of Science, Technology, and Innovation) - Project Number FP44842-38-2017 – contract 038-2017.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ochoa, C., Hernández, M.A., Bayona, O.L. et al. Value-Added By-Products During Dark Fermentation of Agro-Industrial Residual Biomass: Metabolic Pathway Analysis. Waste Biomass Valor 12, 5937–5948 (2021). https://doi.org/10.1007/s12649-021-01421-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01421-1