Abstract

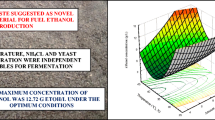

Ethanol production from acid pretreated food waste hydrolysate using immobilized Saccharomyces cerevisiae 74D694 was investigated under different conditions in a batch experiment. Ethanol yield was measured at different time intervals (38, 48, 72, 96 and 105 h) using different immobilized bead ratios (25:100, 30:100, 40:100, 50:100 and 54:100, w/v). Food waste was pretreated using dilute sulphuric acid and the hydrolysate was filtered. The dry food waste had an initial reducing sugar content of 46% (w/w). After dilute acid pretreatment, reducing sugar content increased to 62%. The present study utilized liquid hydrolysate for ethanol production. The process was optimized using central composite design (CCD) a statistical tool used for optimization in response surface methodology (RSM). RSM predicted a maximum ethanol yield of 0.044 g/g of soluble solid in liquid hydrolysate at 40 h fermentation time and immobilized bead ratio of 54:100 (w/v). An experiment was run at the optimal condition and an ethanol yield of 0.047 g/g of soluble solid in liquid hydrolysate was obtained. The predicted result was thus experimentally verified.

Similar content being viewed by others

Abbreviations

- RSM:

-

Response surface methodology

- CCD:

-

Central composite design

- YPD:

-

Yeast peptone dextrose

- ANOVA:

-

Analysis of variance

- FID:

-

Flame ionization detector

- CV:

-

Coefficient of variance

References

Tan, K.T., Lee, K.T., Mohamed, A.R.: Role of energy policy in renewable energy accomplishment: the case of second-generation bioethanol. Energy Policy. 36, 3360–3365 (2008)

Prajapati, V., Trivedi, U., Patel, K.C.: Bioethanol production from the raw corn starch and food waste employing simultaneous saccharification and fermentation approach. Waste Biomass Valoriz. 6, 191–200 (2015)

Liu, B.-F., Xie, G.-J., Wang, R.-Q., Xing, D.-F., Ding, J., Zhou, X., Ren, H.-Y., Ma, C., Ren, N.-Q.: Simultaneous hydrogen and ethanol production from cascade utilization of mono-substrate in integrated dark and photo-fermentative reactor. Biotechnol. Biofuels. 8, 8 (2015)

Matsakas, L., Christakopoulos, P.: Ethanol production from enzymatically treated dried food waste using enzymes produced on-site. Sustain. 7, 1446–1458 (2015)

Silva, V.F.N., Arruda, P. V., Felipe, M.G.A., Gonçalves, A.R., Rocha, G.J.M.: Fermentation of cellulosic hydrolysates obtained by enzymatic saccharification of sugarcane bagasse pretreated by hydrothermal processing. J. Ind. Microbiol. Biotechnol. 38, 809–817 (2011)

Díaz, M.J., Cara, C., Ruiz, E., Romero, I., Moya, M., Castro, E.: Hydrothermal pre-treatment of rapeseed straw. Bioresour. Technol. 101, 2428–2435 (2010)

Pérez, J.A., Ballesteros, I., Ballesteros, M., Sáez, F., Negro, M.J., Manzanares, P.: Optimizing liquid hot water pretreatment conditions to enhance sugar recovery from wheat straw for fuel-ethanol production. Fuel. 87, 3640–3647 (2008)

Pandey, B.K., Vyas, S., Pandey, M., Gaur, A.: Characterisation of municipal solid waste generated from Bhopal, India. Curr. Sci. Perspect. 2, 52–56 (2016)

Barik, S., Paul, K.K.: Potential reuse of kitchen food waste. J. Environ. Chem. Eng. 5, 196–204 (2017)

Srivastava, R., Krishna, V., Sonkar, I.: Characterization and management of municipal solid waste: a case study of Varanasi city, India. Int. J. Curr. Res. Acad. Rev. 2, 10–16 (2014)

Moon, H.C., Song, I.S., Kim, J.C., Shirai, Y., Lee, D.H., Kim, J.K., Chung, S.O., Kim, D.H., Oh, K.K., Cho, Y.S.: Enzymatic hydrolysis of food waste and ethanol fermentation. Int. J. Energy Res. 33, 164–172 (2009)

Alamanou, D.G., Malamis, D., Mamma, D., Kekos, D.: Bioethanol from dried household food waste applying non-isothermal simultaneous saccharification and fermentation at high substrate concentration. Waste Biomass Valoriz. 6, 353–361 (2015)

Han, W., Hu, Y., Li, S., Huang, J., Nie, Q., Zhao, H., Tang, J.: Simultaneous dark fermentative hydrogen and ethanol production from waste bread in a mixed packed tank reactor. J. Clean. Prod. 141, 608–611 (2017)

Han, W., Fang, J., Liu, Z., Tang, J.: Techno-economic evaluation of a combined bioprocess for fermentative hydrogen production from food waste. Bioresour. Technol. 202, 107–112 (2016)

Han, W., Liu, D.N., Shi, Y.W., Tang, J.H., Li, Y.F., Ren, N.Q.: Biohydrogen production from food waste hydrolysate using continuous mixed immobilized sludge reactors. Bioresour. Technol. 180, 54–58 (2015)

Yan, S., Li, J., Chen, X., Wu, J., Wang, P., Ye, J., Yao, J.: Enzymatical hydrolysis of food waste and ethanol production from the hydrolysate. Renew. Energy. 36, 1259–1265 (2011)

Zhang, X., Bury, S., DiBiasio, D., Miller, J.E.: Effects of immobilization on growth, substrate consumption, $β$-galactosidase induction, and byproduct formation in Escherichia coli. J. Ind. Microbiol. Biotechnol. 4, 239–246 (1989)

Gundupalli, M.P., Bhattacharyya, D.: Recovery of reducing sugar from food waste: optimization of pretreatment parameters using response surface methodology. In: Suresh, S., Kumar, A., Shukla, A., Singh, R., Krishna, C.M. (eds.) Biofuels and Bioenergy (BICE2016): International Conference, Bhopal, India, 23–25 February 2016, pp. 161–172. Springer, Cham (2017)

Ma, K., Ruan, Z., Shui, Z., Wang, Y., Hu, G., He, M.: Open fermentative production of fuel ethanol from food waste by an acid-tolerant mutant strain of Zymomonas mobilis. Bioresour. Technol. 203, 295–302 (2016)

Nielsen, S.S.: Food Analysis laboratory manual, 2nd edn. Springer, US

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

Dubois, M., Gilles, K.A., Hamilton, J.K., Rebers, P.A., Smith, F.: Colorimetric method for determination of sugars and related substances. Anal. Chem. 28, 350–356 (1956)

Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D.: Determination of structural carbohydrates and lignin in biomass. Natl. Renew. Energy Lab. Tech. Rep. 1617, 1–16 (2011)

Duarte, J., Rodrigues, J.A., Moran, P.J., Valenca, G., Nunhez, J.: Effect of immobilized cells in calcium alginate beads in alcoholic fermentation. AMB Express. 3, 31 (2013)

Bergman, L.W., Saghbini, M., Hoekstra, D., Gautsch, J.: Growth and maintenance of yeast. Methods Mol. Biol. 177, 9–14 (2001)

Choi, G.W., Um, H.J., Kim, Y., Kang, H.W., Kim, M., Chung, B.W., Kim, Y.H.: Isolation and characterization of two soil derived yeasts for bioethanol production on Cassava starch. Biomass Bioenergy. 34, 1223–1231 (2010)

Laopaiboon, L., Thanonkeo, P., Jaisil, P., Laopaiboon, P.: Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J. Microbiol. Biotechnol. 23, 1497–1501 (2007)

Buzás, Z., Dallmann, K., Szajani, B.: Influenc of pH on the growth and ethanol production of free and immobilized Saccharomyces cerevisiae cells. Biotechnol. Bioeng. 34, 882–884 (1989)

Dutka, M., Ditaranto, M., Løvås, T.: Application of a central composite design for the study of NOx emission performance of a low NOx. Burner. Energies. 8, 3606–3627 (2015)

Montgomery, D.C.: Design and analysis of experiments. Design. 2, 780 ST-design and analysis of experiments. Adva (2001)

Irfan, M., Asghar, U., Nadeem, M., Nelofer, R., Syed, Q., Shakir, H.A., Qazi, J.I.: Statistical optimization of saccharification of alkali pretreated wheat straw for bioethanol production. Waste Biomass Valoriz. 7, 1389–1396 (2016)

Montgomery, D.C., Myers, R.H.: Design and analysis of experiments. In: Meyers, R.H., Montgomery, D.C. (eds.) Response Surface Methodology: Process and Product Optimization Using Designed Experiments. Wiley, Hoboken (1995)

Pandiyan, K., Tiwari, R., Singh, S., Nain, P.K.S., Rana, S., Arora, A., Singh, S.B., Nain, L.: Optimization of enzymatic saccharification of alkali pretreated Parthenium sp. Using response surface methodology. Enzyme Res. 2014 (2014)

Onukwuli, D.O., Emembolu, L.N., Ude, C.N., Aliozo, S.O., Menkiti, M.C.: Optimization of biodiesel production from refined cotton seed oil and its characterization. Egypt. J. Pet. 26, 103–110 (2016)

Selvakumar, S., Manivasagan, R., Chinnappan, K.: Biodegradation and decolourization of textile dye wastewater using Ganoderma lucidum. 3 Biotech. 3, 71–79 (2013)

Walker, K., Vadlani, P., Madl, R., Ugorowski, P., Hohn, K.L.: Ethanol fermentation from food processing waste. Environ. Prog. Sustain. Energy. 32, 1280–1283 (2013)

Kim, J.H., Lee, J.C., Pak, D.: Feasibility of producing ethanol from food waste. Waste Manag. 31, 2121–2125 (2011)

Acknowledgements

This research was funded by Ministry of Human Resource and Development, Government of India, under FAST program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gundupalli, M.P., Bhattacharyya, D. Ethanol Production from Acid Pretreated Food Waste Hydrolysate Using Saccharomyces cerevisiae 74D694 and Optimizing the Process Using Response Surface Methodology. Waste Biomass Valor 10, 701–708 (2019). https://doi.org/10.1007/s12649-017-0077-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0077-9