Abstract

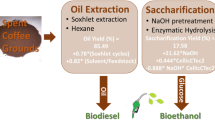

This work aims to explore the production of biodiesel from oil extracted from spent coffee grounds (SCG) via enzymatic catalysis with the Lipozymes RM IM, TL 100L and CALB L, in the presence of a co-solvent, and to optimize the reaction conditions. A three factors design of experiments was performed to evaluate the influence on the reaction performance of ethanol/oil molar ratio, enzyme concentration and reaction temperature. Oil was extracted from air dried SCG with hexane in a pilot solid/liquid extractor, resulting in 6.4% (m/m oil) in dry SCG. The coffee oil was characterized for its kinematic viscosity (38.04 mm2/s), density (0.903 g/cm3), heating value (38 MJ/kg), iodine value (63 g I2/100 g oil), water content (0.1458%), acid value (44.78 mg KOH/g oil), flash point (>120 °C) and triglyceride content (82.8%). Based on the design of experiments, the best conditions for the transesterification reaction are 5:1 molar ratio of ethanol/oil, 4.5% (m/m oil) of enzyme and 45 °C of temperature, resulting in an experimental yield of 96.7%, with 87.6% (m/m) of esters content. Additionally, it was studied the effect of water in the transesterification reaction, using ethanol at 92, 85 and 75% (v/v). Results show that the best reaction yield (97.2%) and esters content (92.1%) were obtained using ethanol 92%. Although the esters content of the biodiesel obtained from coffee oil does not accomplish the EN 14214:2009 requirements, it is promising as there is the possibility to blend the coffee oil with oil from other sources in order to meet the standard requirements.

Similar content being viewed by others

References

MEI, Ministry of Economy and Innovation.: Renewable Energy in Portugal, pp. 38–45 (2007)

e2p, Energias Endógenas de Portugal.: Wind Farms in Portugal, pp. 10–12 (2015)

Mata, T.M., Sousa, I.R.B.G., Vieira, S.S., Caetano, N.S.: Biodiesel production from corn oil via enzymatic catalysis with ethanol. Energy Fuels. 26(5), 3034–3041 (2012)

EurObserv’ER.: Biofuels-Barometer. http://www.eurobserv-er.org/biofuels-barometer-2015/ (2015). Accessed 6 Sept 2015

Chesterfield, D.M., Rogers, P.L., Al-Zaini, E.O., Adesina, A.A.: Production of biodiesel via ethanolysis of waste cooking oil using immobilised lipase. Chem. Eng. J. 207–208, 701–710 (2012)

Nitièma-Yefanova, S., Coniglio, L., Schneider, R., Nébié, R.H.C., Bonzi-Coulibaly, Y.L.: Ethyl biodiesel production from non-edible oils of Balanites aegyptiaca, Azadirachta indica, and Jatropha curcas seeds—Laboratory scale development. Renew. Energy 96 A, 881–890 (2016)

Demirbas, A.: Biodiesel production from vegetable oils via catalytic and noncatalytic supercritical methanol transesterification methods. Prog. Energy Combust. Sci. 31, 466–487 (2005)

Mata T.M., Cardoso N., Ornelas M., Neves S., Caetano N.S.: Sustainable production of biodiesel from tallow, lard and poultry and its quality evaluation. Chem. Eng. Trans. 19, 13–18. (2010)

Mata, T.M., Cardoso, N., Ornelas, M., Neves, S., Caetano, N.S.: Evaluation of two purification methods of biodiesel from beef tallow, pork lard, and chicken fat. Energy Fuels 25(10), 4756–4762 (2011)

Moser, B.: Biodiesel production, properties, and feedstocks. In Vitro Cell. Dev. Biol. Plant 45(3), 229–266 (2009)

Caetano, N.S., Silva, V.F.M., Mata, T.M.: Valorization of coffee grounds for biodiesel production. Chem. Eng.Trans. 26, 267–272 (2012)

AICC.: Origins & History. http://www.aicc.pt/origem_historia.html (2011). Accessed 8 Sept 2015

ECF.: Coffee Consumption in Europe. http://www.ecf-coffee.org/about-coffee/coffee-consumption-in-europe (2014). Accessed 6 Sept 2015

Ferreira, A.: Influence of SCG in the growth and the chemical and biological properties of lettuce plants (Lactuca sativa L.) [in Portuguese]. Master Thesis in Quality and Food Safety, Instituto Politécnico de Bragança (2011)

Mussatto, S.I., Machado, E. M. S., Martins, S., Teixeira, J. A.: Production, composition, and application of coffee and its industrial residues. Food and Bioprocess Technol. 4(5), 661–672 (2011)

Mussatto, S.I., Carneiro, L.M., Silva, J.P.A., Roberto, I.C., Teixeira, J.A.: A study on chemical constituents and sugars extraction from spent coffee grounds. Carbohydr. Polym. 83(2), 368–374 (2011)

Machado, E.M.S., Rodriguez-Jasso, R.M., Teixeira, J.A., Mussatto, S.I.: Growth of fungal strains on coffee industry residues with removal of polyphenolic compounds. Biochem. Eng. J. 60, 87–90 (2012)

ChartsBin statistics collector team 2011.: Current Worldwide Annual Coffee Consumption per capita, ChartsBin.com. http://chartsbin.com/view/581 (2016). Accessed 14 Oct 2016

Deligiannis, A., Papazafeiropoulou, A., Anastopoulos, G., Zannikos, F.: Waste coffee grounds as an energy feedstock. Proceedings of the 3rd International CEMEPE & SECOTOX Conference, Laboratory of Fuel Technology and Lubricants, School of Chemical Engineering, National Technical University of Athens, 617–622 (2011)

Park, J., Kim, B., Lee, J.W.: In-situ transesterification of wet spent coffee grounds for sustainable biodiesel production. Bioresour. Technol. 221, 55–60 (2016)

Caetano, N. S., Silva, V. F. M., Melo, A. C., Martins, A. A., Mata, T. M.: Spent coffee grounds for biodiesel production and other applications. Clean Technol. Environ. Policy 16(7), 1423–1430 (2014)

Al-Hamamre, Z., Foerster, S., Hartmann, F., Kröger, M., Kaltschmitt, M.: Oil extracted from spent coffee grounds as a renewable source for fatty acid methyl ester manufacturing. Fuel 96, 70–76 (2012)

Jenkins, R.W., Stageman, N.E., Fortune, C.M., Chuck, C.J.: Effect of the type of bean, processing, and geographical location on the biodiesel produced from waste coffee grounds. Energy Fuels 28(2), 1166–1174 (2014)

Caetano, N.S., Teixeira, J.M.I., Mata, T.M.: Enzymatic catalysis of vegetable oil with ethanol in the presence of co-solvents. Chem. Eng. Trans. 26, 81–86 (2012)

Mata, T.M., Sousa, I.R.B.G., Caetano, N.S.: Transgenic corn oil for biodiesel production via enzymatic catalysis with ethanol. Chem. Eng. Trans. 27, 19–24 (2012)

Marchetti, J.M., Miguel, V.U., Errazu, A.F.: Possible methods for biodiesel production. Renew. Sustain. Energy Rev. 11, 1300–1311 (2007)

Soumanou, M.M., Bornscheuer, U.T.: Improvement in lipase-catalyzed synthesis of fatty acid methyl esters from sunflower oil. Enzyme Microb. Technol. 33(1), 97–103 (2003)

Bajaj, A., Lohan, P., Jha, P.N., Mehrotra, R.: Biodiesel production through lipase catalyzed transesterification: an overview. J. Mol. Catal. B Enzym. 62(1), 9–14 (2010)

Ribeiro, L.A., da Silva, P.P., Mata, T.M., Martins, A.A.: Prospects of using microalgae for biofuels production: results of a Delphi study. Renew. Energy 75, 799–804 (2015)

Mata, T.M., Tavares, T.F., Meireles, S., Caetano, N.S. Bioethanol from brewers’ spent grain: pentose fermentation. Chem. Eng. Trans. 43, 241–246 (2015)

Caetano, N.S., Moura, R.F., Meireles, S., Mendes, A.M., Mata, T.M., Bioethanol from brewer’s spent grains: Acid pretreatment optimization. Chem. Eng. Trans. 35, 1021–1026 (2013)

Alves, B., Nascimento, E., Aquino, F., Chang, R., Morais, S.: Chemical composition of roasted coffee from the Cerrado and South Minas Gerais [Composição química de cafés torrados do Cerrado e do Sul de Minas Gerais] (in Portuguese). Ciênc. Eng. 16(1/2), 9–15 (2007)

APHA.: Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association, Washington, DC (1999)

Vinod, K., Firdaus, J., Saxena, R.K.: Efficient production methodology for biodiesel from non-edible karanja oil and its fuel characterization study. Int. J. Ext. Res. 1, 36–40 (2014)

Li, X., Strezov, V., Kan, T.: Energy recovery potential analysis of spent coffee grounds pyrolysis products. J. Anal. Appl. Pyrolysis. 110, 79–87 (2014)

Caldeira, D.: Valorization of SCG: optimization of biodiesel production by enzymatic catalysis. [in Portuguese] Master Thesis in Chemical Engineering, ISEP (2015)

López-Barrera, D.M., Vázquez-Sánchez, K., Loarca-Piña, M.G.F., Campos-Vega, R.: Spent coffee grounds, an innovative source of colonic fermentable compounds, inhibit inflammatory mediators in vitro. Food. Chem. 212, 282–290 (2016)

Haile, M.: Integrated valorization of spent coffee grounds to biofuels. Biofuel Res. J. 2, 65–69 (2014)

Wagner, M.: Enzyme kinetics, behavior and analysis of rapid equilibrium and steady-state enzyme systems (Segel, Irwin H.). J. Chem. Educ. 53(11), A472 (1976)

Rocha, M.V.P., Matos, L.J.B.L., Lima, L.P., Figueiredo, P.M.S., Lucena, I.L., Fernandes, F.A.N., Gonçalves, L.R.B: Ultrasound-assisted production of biodiesel and ethanol from spent coffee grounds. Bioresour. Technol. 167, 343–348 (2014)

Vardon, D.R., Moser, B.R., Zheng, W., Witkin, K., Evangelista, R.L., Strathmann, T.J., Rajagopalan, K., Sharma, B.K.: Complete utilization of spent coffee grounds to produce biodiesel, bio-oil, and biochar. ACS Sustain. Chem. Eng. 1(10), 1286–1294 (2013)

Kwon, E.E., Yi, H., Jeon, Y.J.: Sequential co-production of biodiesel and bioethanol with spent coffee grounds. Bioresour. Technol. 136, 475–480 (2013)

Döhlert, P., Weidauer, M., Enthaler, S.: Spent coffee ground as source for hydrocarbon fuels. J. Energy Chem. 25(1), 146–152 (2016)

Hernández-Martín, E., Otero, C.: Different enzyme requirements for the synthesis of biodiesel: Novozym® 435 and Lipozyme® TL IM. Bioresour. Technol. 99(2), 277–286 (2008)

Barton, J.S.: Denaturation at the optimum temperature. Biochem. Educ. 7(1), 13–14 (1979)

Acknowledgements

This work was financially supported by: Project FCT UID/EQU/00305/2013 and Project POCI-01-0145-FEDER-006939 (Laboratory for Process Engineering, Environment, Biotechnology and Energy—LEPABE) funded by FEDER funds through COMPETE2020—Programa Operacional Competitividade e Internacionalização (POCI)—and by national funds through FCT—Fundação para a Ciência e a Tecnologia; T. Mata and A. Martins would like to thank FCT—Fundação para a Ciência e a Tecnologia for their support through provision of research grants with references respectively, IF/01093/2014 and SFRH/BPD/112003/2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Caetano, N.S., Caldeira, D., Martins, A.A. et al. Valorisation of Spent Coffee Grounds: Production of Biodiesel via Enzymatic Catalysis with Ethanol and a Co-solvent. Waste Biomass Valor 8, 1981–1994 (2017). https://doi.org/10.1007/s12649-016-9790-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9790-z