Abstract

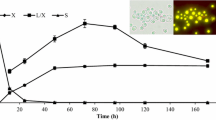

By-products streams from a sunflower-based biodiesel plant were utilised for the production of fermentation media that can be used for the production of polyhydroxyalkanoates (PHA). Sunflower meal was utilised as substrate for the production of crude enzyme consortia through solid state fermentation (SSF) with the fungal strain Aspergillus oryzae. Fermented solids were subsequently mixed with unprocessed sunflower meal aiming at the production of a nutrient-rich fermentation feedstock. The highest free amino nitrogen (FAN) and inorganic phosphorus concentrations achieved were 1.5 g L−1 and 246 mg L−1, respectively, when an initial proteolytic activity of 6.4 U mL−1 was used. The FAN concentration was increased to 2.3 g L−1 when the initial proteolytic activity was increased to 16 U mL−1. Sunflower meal hydrolysates were mixed with crude glycerol to provide fermentation media that were evaluated for the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (P(3HB-co-3HV)) using Cupriavidus necator DSM 545. The P(3HB-co-3HV) (9.9 g l−1) produced contained 3HB and 3HV units with 97 and 3 mol %, respectively. Integrating PHA production in existing 1st generation biodiesel production plants through valorisation of by-product streams could improve their sustainability.

Similar content being viewed by others

References

Lamers, P.: International biodiesel markets. Developments in production and trade. Published http://www.ecofys.com/en/publication/international-biodiesel-markets/ (2012)

Krawczyk, T.: Biodiesel—alternative fuel makes inroads but hurdles remain. INFORM 7, 801–829 (1996)

Ma, F., Hanna, M.A.: Biodiesel production: a review. Bioresour. Technol. 70, 1–15 (1999)

Dorado, M.P., Ballesteros, E., Arnal, J.M., Gómez, J., López-Giménez, F.J.: Testing waste olive oil methyl ester as a fuel in a diesel engine. Energ. Fuel 17(6), 1560–1565 (2003)

Panoutsou, C., Namatov, I., Lychnaras, V., Nikolaou, A.: Biodiesel options in Greece. Biomass Bioenerg. 32, 473–481 (2008)

United States Department of Agriculture. Foreign Agricultural Service. Production, Supply and Distribution Online. Accessed 21 Sep 2012. http://www.fas.usda.gov/psdonline/psdquery.aspx

Papanikolaou, S., Muniglia, L., Aggelis, G., Marc, I.: Yarrowia lipolytica as a potential producer of citric acid from raw glycerol. J. Appl. Microbiol. 92(4), 737–744 (2002)

Da Silva, G.P., Mack, M., Contiero, J.: Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol. Adv. 27, 30–39 (2009)

Chatzifragkou, A., Papanikolaou, S., Dietz, D., Doulgeraki, A.I., Nychas, G.J., Zeng, A.P.: Production of 1,3-propanediol by Clostridium butyricum growing on biodiesel-derived crude glycerol through a non-sterilised fermentation process. Appl. Microbiol. Biotechnol. 91(1), 101–112 (2011)

Lee, P.C., Lee, W.G., Chang, H.N.: Succinic acid production with reduced by-product formation in the fermentation of Anaerobiospirillum succiniciproducens using glycerol as a carbon source. Biotechnol. Bioenerg. 72(1), 41–48 (2001)

Ito, T., Nakashimada, Y., Senba, K., Matsui, T., Nishio, N.: Hydrogen and ethanol production from glycerol-containing wastes discharged after biodiesel manufacturing process. J. Biosci. Bioeng. 100(3), 260–265 (2005)

Ashby, R.D., Solaiman, D.K.Y., Foglia, T.A.: Bacterial poly(hydroxyalkanoate) polymer production from the biodiesel co-product stream. J. Polym. Environ. 12(3), 105–112 (2004)

Solaiman, D.K.Y., Ashby, R.D., Foglia, T.A., Marmer, W.N.: Conversion of agricultural feedstock and co-products into poly(hydroxyalkanoates). Appl. Microbiol. Biotechnol. 71, 783–789 (2006)

National Sunflower Association. Meal/Wholeseed feeding. Accessed 19 Sep 2012. http://www.sunflowernsa.com/wholeseed/sunflower-as-a-feed/

Lomascolo, A., Uzan-Boukhris, E., Sigoillot, J.C., Fine, F.: Rapeseed and sunflower meal: a review on biotechnology status and challenges. Appl. Microbiol. Biotechnol. (2012). doi:10.1007/s00253-012-4250-6

Sircar, A., Sridhar, P., Das, P.K.: Optimization of solid state medium for the production of clavulanic acid by Streptomyces clavuligerus. Process Biochem. 33(3), 283–289 (1998)

Sarada, I., Sridhar, P.: Nutritional improvement for cephamycin C fermentation using a superior strain of Streptomyces clavuligerus. Process Biochem. 33(3), 317–322 (1998)

Jacobs, A., Botha, A., Reddy, J.K., Van Zyl, W.H.: Sunflower press cake as a substrate for eicosipentaenoic acid production by representatives of the genus Mortierella. Bioresources 5(2), 1232–1243 (2010)

Jadhav, M., Kagalkar, A., Jadhav, S., Govindwar, S.: Isolation, characterization, and antifungal application of a biosurfactant produced by Enterobacter sp. MS16. Eur. J. Lipid Sci. Tech. 113(11), 1347–1356 (2011)

Rajoka, M.I., Huma, T., Khalid, A.M., Latif, F.: Kinetics of enhanced substrate consumption and endo-β-xylanase production by a mutant derivative of Humicola lanuginose in solid-state-fermentation. World J. Microb. Biot. 21(6–7), 869–876 (2005)

Ashby, R., Solaiman, D.K.Y., Strahan, G.D.: Efficient utilization of crude glycerol as fermentation substrate in the synthesis of poly(3-hydroxybutyrate) biopolymers. J. Am. Oil Chem. Soc. 88(7), 949–959 (2011)

Cavalheiro, J.M.B.T., de Almeida, M.C.M.D., Grandfils, C., da Fonseca, M.M.R.: Poly(3-hydroxybutyrate) production by Cupriavidus necator using waste glycerol. Proc. Biochem. 44(5), 509–515 (2009)

Cavalheiro, J.M.B.T., Raposo, R.S., de Almeida, M.C.M.D., Cesário, M.T., Sevrin, C., Grandfils, C., da Fonseca, M.M.R.: Effect of cultivation parameters on the production of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxybutyrate-4-hydroxybutyrate-3-hydroxyvalerate) by Cupriavidus necator using waste glycerol. Bioresour. Technol. 111, 391–397 (2012)

Mothes, G., Schnorpfeil, C., Ackermann, J.-U.: Production of PHB from crude glycerol. Eng. Life Sci. 7, 475–479 (2007)

Wang, R., Law, R.C.S., Webb, C.: Protease production and conidiation by Aspergillus oryzae in flour fermentation. Proc. Biochem. 40, 217–227 (2005)

American Association of Cereal Chemists Inc (AACC): Approved Methods of the American Association of Cereal Chemists. 8th ed., St. Paul, MN, USA (1983)

Riis, V., Mai, W.: Gas chromatographic determination of poly-b-hydroxybutyric acid in microbial biomass after hydrochloric acid propanolysis. J. Chromatogr. A445, 285–289 (1988)

Lie, S.: The EBC-ninhydrin method for determination of free alpha amino nitrogen. J. Inst. Brew. 79, 37–41 (1973)

Harland, B.F., Harland, J.: Fermentative reduction of phytate in rye, white and whole wheat breads. Cereal Chem. 57, 226–229 (1980)

Parrado, J., Millan, F., Hernandez-Pinzh, I., Bautista, J., Machado, A.: Characterization of enzymatic sunflower protein hydrolysates. J. Agric. Food Chem. 41, 1821–1825 (1993)

Bautista, J., Parrado, J., Machado, A.: Composition and fractionation of sunflower meal: use of the lignocellulosic fraction as substrate in solid state fermentation. Biol. Waste 32(3), 225–233 (1990)

Salunkhe, D.K., Chavan, J.K., Adsule, R.N., Kadam, S.S.: Sunflower. In: Salunkhe, D.K., Adsule, R.N., Chavan, J.K., Kadam, S.S. (eds.) World Oilseeds: Chemistry, Technology and Utilization, pp. 97–139. Van Nostrand Reinhold, New York (1992)

Gassmann, B.: Preparation and application of vegetable proteins, especially proteins from sunflower seed, for human consumption. App. Die Nahrung 27, 351–369 (1983)

Bhatty, R.S., Sosulski, F.W., Wu, K.K.: Protein and nonprotein nitrogen contents of some oilseeds and peas. Can. J. Plant Sci. 53, 651–657 (1973)

Villanueva, A., Vioque, J., Sánchez-Vioque, R., Clemente, A., Bautista, J., Millán, F.: Production of an extensive sunflower protein hydrolysate by sequential hydrolysis with endo- and exo-proteases. Grasas Aceites 50(6), 472–476 (1999)

Kiran, E.U., Salakkam, A., Trzcinski, A.P., Bakir, U., Webb, C.: Enhancing the value of nitrogen from rapeseed meal for microbial oil production. Enz. Microb. Technol. 50, 337–342 (2012)

Wang, R., Shaarani, S., Md Godoy, L.C., Melikoglu, M., Vergara, C.S., Koutinas, A., Webb, C.: Bioconversion of rapeseed meal for the production of a generic microbial feedstock. Enz. Microb. Technol. 47, 77–83 (2010)

Whitaker, J.R.: Enzyme-catalyzed reactions experimental factors that affect rates. In: Whitaker, J.R., Voragen, A.G.J., Wong, D.W.S. (eds.) Handbook of Food Enzymology, pp. 43–48. Marcel Dekker Inc., New York (2000)

Wang, R., Godoy, L.C., Shaarani, S., Melikoglu, M., Koutinas, A., Webb, C.: Improving wheat flour hydrolysis by an enzyme mixture from solid state fungal fermentation. Enz. Microb. Technol. 44, 223–228 (2009)

Koutinas, A., Wang, R.H., Webb, C.: Development of a process for the production of nutrient supplements for fermentations based on fungal autolysis. Enz. Microb. Technol. 36, 629–638 (2005)

Koutinas, A.A., Xu, Y., Wang, R., Webb, C.: Polyhydroxybutyrate production from a novel feedstock derived from a wheat-based biorefinery. Enz. Microb. Technol. 40, 1035–1044 (2007)

Xu, Y., Wang, R.H., Koutinas, A., Webb, C.: Microbial biodegradable plastic production from a wheat-based biorefining strategy. Proc. Biochem. 45, 153–163 (2010)

Steinbüchel, A., Lütke-Eversloh, T.: Metabolic engineering and pathway construction for biotechnological production of relevant polyhydroxyalkanaotes in microorganisms. Biochem. Eng. J. 16, 81–96 (2003)

Geneau-Sbartai, C., Leyris, J., Silvestre, F., Rigal, L.: Sunflower cake as a natural composite: composition and plastic properties. J. Agric. Food Chem. 56, 11198–11208 (2008)

Acknowledgments

This work is part of the “BIOREF” project (09SYN-81-715), implemented within the National Strategic Reference Framework (NSRF) 2007–2013 and co-financed by National (Greek Ministry—General Secretariat of Research and Technology) and Community Funds (E.U.-European Social Fund).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kachrimanidou, V., Kopsahelis, N., Chatzifragkou, A. et al. Utilisation of By-Products from Sunflower-Based Biodiesel Production Processes for the Production of Fermentation Feedstock. Waste Biomass Valor 4, 529–537 (2013). https://doi.org/10.1007/s12649-012-9191-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-012-9191-x