Abstract

Purpose

The pyrolysis thermal treatment of several waste such as polymers (PE, PVC, PS), sewage sludge, tyres, waste wood as spruce sawdust and the successive stabilization of the pyrolysis residue has been investigated on analytical and energetic point of view. This thermal process has been considered as it allows the reduction of the waste mass with the recovery of its energy content, through the exploitation of the produced gas phase as fuel.

Methods

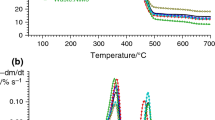

Analyzed plastics are pure polymers: Polyethylene “Riblene FF22” and polystyrene “Edistir 1910” furnished by Enichem, while polyvinylchloride has been a K57 PVC furnished by EVC. The sewage sludge sample derives from the urban wastewater treatment plant of Trento, while the waste tyre is a SMR 10 Marangoni tyre. Spruce sawdust has been furnished by a neighbouring sawmill. The pyrolysis of the above indicated solid waste was studied by thermogravimetry coupled to mass spectrometry, TG-MS and TG-GC–MS. This analytical approach was followed by pyrplysis tests, carried out on a selection of the waste materials, by using a pyrolysis bench scale reactor.

Result

The pyrolysis of all the wastes takes place in the range of 400–600°C and leads the reduction of the 90% of the mass for plastics, 50% for sludge, and ca. 60% for tyres, with production of a fuel gas phase particularly rich in hydrocarbons, with a estimated LHV from 15 to 32.8 MJ/kg for sewage sludge and plastics, respectively. A schematic energetic analysis is proposed implementing the pyrolysis stage with a vitrification process in order to obtain, in particular for sewage sludge residue, a product environmental friendly to use as raw material in industry.

Conclusions

The promising perspective of a two steps pyrolysis–vitrification process has been investigated to exploit the heating power of the resulting gas phase and to solve the environmental impact of heavy metals. The proposed analytical and energetic analysis looks promising for future improvements of this type of processes.

Similar content being viewed by others

References

Shen, L., Zhang, D.: An experimental study of oil recovery from sewage sludge by low-temperature pyrolysis in a fluidised-bed. Fuel 82, 465–472 (2003)

Fullana, A., Conesa, J.A., Font, R., Martín-Gullón, I.: Pyrolysis of sewage sludge: nitrogenated compounds and pretreatment effects. J. Anal. Appl. Pyrolysis 68–69, 561–575 (2003)

Karaduman, A., Şimşek, E.H., Çiçek, B., Bilgesü, A.Y.: Flash pyrolysis of polystyrene wastes in a free-fall reactor under vacuum. J. Anal. Appl. Pyrolysis 60, 179–186 (2001)

Gao, Z., Amasaki, I., Nakada, M.: A thermogravimetric study on thermal degradation of polyethylene. J. Anal. Appl. Pyrolysis 67, 1–9 (2003)

Colombo, P., Brusatin, G., Bernardo, E., Scarinci, G.: Inertization and reuse of waste materials by vitrification and fabrication of glass-based products. Curr. Opin. Solid State Mater. Sci. 7, 225–239 (2003)

Ragazzi, M., Rada, E.C., Ischia, M., Dal Maschio, R.: Recycling of slag and fly-ash from MSW incineration for a zero-ing landfilling strategies. In: Proceedings of ISEST 2009: International Symposium on Environmental Science and Technology, pp. 2197–2205, 2–5 June, Shanghai, China (2009)

Campostrini, R., Ischia, M., Palmisano, L.: Pyrolysis study of sol–gel derived TiO2 powders. Part 1: TiO2-anatase prepared by reacting Titanium(IV) isopropoxide with formic acid. J. Therm. Anal. Calorim. 71, 997–1009 (2003)

Baggio, P., Barattieri, M., Fiori, L., Grigiante, M., Avi, D., Tosi, P.: Experimental and modeling analysis of a batch gasification/pyrolysis reactor. Energy Convers. Manage. 50, 1426–1435 (2009)

Ischia, M., Perazzolli, C., Dal Maschio, R., Campostrini, R.: Pyrolysis study of sewage sludge by TG-MS and TG-GC-MS coupled analyses. J. Therm. Anal. Cal. 87, 567–574 (2007)

Ischia, M., Perazzolli, C., Dal Maschio, R., Tognana, L., Ragazzi, M., Rada, E.C.: TG-MS/TG-GC-MS for the pyrolysis characterization of sewage and refinery sludge. In: Proceedings of “Chania 2008: 1st International Conference on Hazardous Waste Mangement,” Chania-Crete, Greece, 1–3 October 2008

Arenillas, A., Rubiera, F., Pis, J.J.: Simultaneous thermogravimetric-mass spectrometric study on the pyrolysis behaviour of different rank coals. J. Anal. Appl. Pyrolysis 50, 31–46 (1999)

Otero, M., Díez, C., Calvo, L.F., García, A.I., Morán, A.: Analysis of the co-combustion of sewage sludge and coal by TG-MS. Biomass Bioenergy 22, 319–329 (2002)

Bockhorn, H., Hornung, A., Hornung, U., Schawaller, D.: Kinetic study on the thermal degradation of polypropylene and polyethylene. J. Anal. Appl. Pyrolysis 48, 93–109 (1999)

Faravelli, T., Bozzano, G., Scassa, C., Perego, M., Fabini, S., Ranzi, E., Dente, M.: Gas product ditribution from polyethylene pyrolysis. J. Anal. Appl. Pyrolysis 52, 87–103 (1999)

Swistek, M., Nguyen, G., Nicole, D.: Contribution to the modelling of pre-depolymerisation of polystyrene. J. Anal. Appl. Pyrolysis 37, 15–26 (1996)

Faravelli, T., Pinciroli, M., Pisano, F., Bozzano, G., Dente, M., Ranzi, E.: Thermal degradation of polystyrene. J. Anal. Appl. Pyrolysis 60, 103–121 (2001)

Dadvand, N., Lehrle, R.S., Parsons, I.W., Rollinson, M.: Use of pyrolysis-g.c.-m.s. to asses the thermal degradation behaviour of polymers containing chlorine I. The limits of detection and measurement of HCl, deduced from a study of PVC pyrolysis. Polym. Degrad. Stab. 66, 247–255 (1999)

Sun, Q., Shi, X., Lin, Y., Zhu, H., Wang, X., Cheng, C., Liu, J.: Thermogravimetric-mass spectrometric study of the pyrolysis behavior of PVC. J. China Univ. Mining Technol. 17(2), 242–245 (2007)

Ragazzi, M., Ischia, M., Perazzolli, C., Dal Maschio, R., Tognana, L., Rada, E.C.: Pyrolysis study of worn-out tyres. In: Proceedings of “Venice 2008 Second International Symposium on Energy from Biomass and Waste,” Venice, Italy 17–20 November 2008

Berrueco, C., Esperanza, E., Mastral, F.J., Ceamanos, J., García-Bacaicoa, P.: Pyrolysis of waste tyres in an atmospheric static-bed batch reactor: analysis of the gases obtained. J. Anal. Appl. Pyrolysis 74, 245–253 (2005)

Boxiong, S., Chunfei, W., Wang, R., Guo, B., Liang, C.: Pyrolysis of scrap tyres with zeolite USY. J. Hazard. Mater. B137, 1065–1073 (2006)

Chagqing, D., Yongping, Y., Baosheng, J., Masayuki, H.: The pyrolysis of sawdust and polyethylene in TG and U-shape tube reactor. Waste Manage. 27, 1557–1561 (2007)

Ulloa, C.A., Gordon, A.L., García, X.A.: Thermogravimetric study of interactions in the pyrolysis of blends of coal with radiata pine sawdust. Fuel Process. Technol. 90, 583–590 (2009)

Falcone, R., Hreglich, S., Profilo, B., Vallotto, M.: Inertizzazione di miscele di ceneri e scorie da RSU mediante vetrificazione e valorizzazione del vetro prodotto. Rivista della Stazione Sperimentale del Vetro 4, 25–29 (2003)

Pisciella, P., Crisucci, S., Karamanov, A., Pelino, M.: Chemical durability of glasses obtained by vitrification of industrial wastes. Waste Manage. 21, 1–9 (2001)

Baratieri, M., Baggio, P., Fiori, L., Grigiante, M.: Biomass as an energy source: thermodynamic constraints on the performance of the conversion process. Bioresour. Technol. 99, 7063–7073 (2008)

Schuster, G., Löffler, G., Weigl, K., Hofbauer, H.: Biomass steam gasification–an extensive parametric modeling study. Bioresour. Technol. 77, 71–79 (2001)

Altafini, C.R., Wander, P.R., Barreto, R.M.: Prediction of the working parameters of a wood waste gasifier through an equilibrium model. Energy Convers. Manage. 44, 2763–2777 (2003)

Goodwin, D.: Cantera: object oriented software for reacting flows. California Institute for Technology (Caltech). http://www.cantera.org (2006)

Smith, W.R., Missen, R.W.: Chemical Reaction Equilibrium Analysis: Theory and Algorithm. Wiley Interscience, New York (1982)

McBride, B.J., Gordon, S., Reno, M.A.: Coefficients for calculating thermodynamic and transport properties of individual specie, NASA Report TM-4513 (1993)

Smith, G.P., Golden, D.M., Frenklach, M., Moriarty, N.W., Eiteneer, B., Goldenberg, M., Bowman, C.T., Hanson, R.K., Song, S., Gardiner, W.C. Jr., Lissianski, V.V., Qin, Z.: GRI-Mech 3.0. http://www.me.berkeley.edu/gri_mech (2007)

Tenti, R., Camiciola, P.: Termovalorizzazione dei rifiuti tramite pirolisi e impianto a ciclo combinato per la produzione di energia elettrica e calore. In: Morselli, L. (ed.) Ecomondo 22/25 ottobre 2003 Rimini. Atti dei Seminari, pp. 163–173. Maggioli, Rimini (2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grigiante, M., Ischia, M., Baratieri, M. et al. Pyrolysis Analysis and Solid Residue Stabilization of Polymers, Waste Tyres, Spruce Sawdust and Sewage Sludge. Waste Biomass Valor 1, 381–393 (2010). https://doi.org/10.1007/s12649-010-9038-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-010-9038-2