Abstract

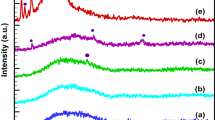

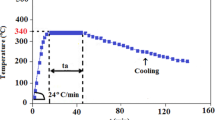

In the present work, Cu-doped indium sulfide thin films (In2S3:Cu) have been produced by chemical bath deposition (CBD) method on the glass substrates. The deposited films have been post-annealed at 300 °C temperature for about one hour. The morphological properties of produced thin films have been investigated analytically before and after the Cu doping process. To this end, the atomic force microscopy analysis has been used to study the height fluctuations of these rough thin films. By the monofractal analysis, the height distribution, and the higher-order moments (skewness and kurtosis) of the surface height have been studied. The deviation from the Gaussian distribution has been shown by the results. Also, the correlation function and therefore the correlation length of the produced surfaces have been investigated. The numerical calculations revealed that the morphology and the statistical properties of thin films depend on the growth method. The power spectral density has been evaluated, and the achieved results of higher-order moments of the surface height have been confirmed. The skewness values of thin films heights are nonzero; moreover, the obtained kurtosis values illustrate the mild peak respect to Gaussian distribution. The Hurst exponent and thus the fractal dimensions of surfaces have been estimated.

Similar content being viewed by others

References

J Feng, Z Yang, S He, X Niu, T Zhang, A Ding and X Liang Hand Feng Chemosphere 212 114 (2018)

F Aslan, G Adam, P Stadler and A Goktas Sol. Energy 108 230 (2014)

A Y Kim, T S Senthil, B S Kwak and M Kang Mater. Chem. Phys. 149–150 302 (2015)

A Beaurain, D Luxembourg, C Dufour, V Koncar, B Capoen and M Bouazaoui Thin Solid Films 516 4102 (2008)

R Souissi and A Bouguila Nand Labidi Sensors Actuators B 261 522 (2018)

A Timoumi, H Bouzouita, M Kanzari and B Rezig Thin Solid Films 480–481 124 (2005)

O Pobncelet, R Kotipalli, B Vermang, A Macleod, L A Francis and D Flandre Sol. Energy 146 443 (2017)

W Rehwald and G Harbeke J. Phys. Chem. Solids 26 1309 (1965)

K Kambas, J Spyridelis and M Balkanski Phys. Status Solidi B 105 291 (1981)

M C Sosa-Muñiz, M Sanchez Tizapa, R CastañedaValderrama, M A Carreón Álvarez, A Suárez Gómez, J P Morán Lázaro, O HernándezCristobal and M FloresMartínez Thin Solid Films 616 388 (2016)

T Sall, B M Soucase, M Mollar, B Hartitti and M Fahoume J. Phys. Chem. Solids 76 100 (2015)

Z Li, X Tao, Z Wu, P Zhang and Z Zhang Ultrason. Sonochem. 16 221 (2009)

N A Allsop, A Scho¨nmann, H J Muffler, M Bar, M C Lux-Steiner and Ch-H Fisher Prog. Photovolt. Res. Appl. 13 607 (2005)

W Lee, S Baek, R S Mane, V V Todkar, O Egorova, W S Chae, S Lee and S H Han Curr. Appl. Phys. 9 62 (2009)

N Barreau, A Mokrani, F Couzinie´-Devy and J Kessler Thin Solid Films 517 2316 (2009)

P Esmaili, H Kangarlou, H Savaloni and M Ghorannevis Result Phys. https://doi.org/10.1016/j.rinp.2017.08.062

N Kammoun, S Belgacem, M Amlouk, R Bennaceur, J Bonnet, F Touhari, M Nouaoura and L Lassabatere J. Appl. Phys. 29 2766 (2001)

T Nakada and M Mizutani Jpn. J. Appl. Phys. 41 165 (2002)

M Gossla, H E Mahnke and H Metzner Thin Solid Films 361 56 (2000)

A Katerski, M Danilson, A Mere and M Krunks Thin Solid Films 2 103 (2009)

S Shirakata, T Murakami, T Kariya and S Isomura Jpn. J. Appl. Phys. 35 191 (1996)

M C Zougi, T Ben Nasvallah, S Marsillac, J C Bernede and S Belgacem Thin Solid Films 382 39 (2001)

L S Parshina, O D Khramova, O A Novodvorsky, A A Lotin, I A Petukhov, F N Putilin and K D Shcherbachev Semiconductors 51 407 (2017)

S M Bazarchi, P Esmaili and S Asgary Eur. Phys. J. Appl. Phys. 92 30301 (2020)

M Krunks, O Bijakina, T Varema, V Mikli and E Mellikov Thin Solid Films 362 61 (1991)

S M Pawar, B S Pawar, J H Kim, O S Joo and C D Lokhande Curr. Appl. Phys. 11 117 (2011)

M Nasiri Sarvi, P Esmaili and S Asgary Indian J. Phys. https://doi.org/10.1007/s12648-019-01601-9

J A Ogilvy and J R Foster J. Phys. D Appl. Phys 22 1243 (1989)

D G Chetwynd, J A Greenwood and E Mainsah Metrology and Properties of Engineering Surfaces (2001)

R P Yadav, S Dwivedib, A K Mittala, M Kumar and A C Pandey Appl. Surf. Sci. 261 547(2012)

A L Barabasi and H E Stanley Fractal Concepts in Surface Growth (New York: Cambridge University Press) (1995)

W Z Wang, H Chen and Y Z Hu Tribol. Int. 39 522 (2006)

B N J Persson Tribol. Lett. 54 99 (2014)

R Hübler Surf. Coat. Technol. 116 1111 (1999)

R P Yadav, T Kumar and A K Mittal Appl. Surf. Sci. 347 706 (2015)

G Palasantzas, J. Barnasa and Th M. De Hosson J. Appl. Phys. 88 927 (2000)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ebrahiminejad, Z., Asgary, S. & Esmaili, P. Surface characterization of Cu-doped indium sulfide thin films. Indian J Phys 96, 1315–1319 (2022). https://doi.org/10.1007/s12648-021-02044-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-021-02044-x