Abstract

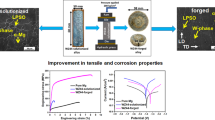

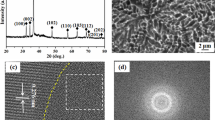

In this work, the powder metallurgy method has been used to synthesis nano-sized B4C and SiC reinforcement AA2024 matrix hybrid nanocomposite. The effect of B4C and SiC reinforcement content on mechanical and corrosion behavior of AA2024-B4C/SiC hybrid nanocomposite was examined. The corrosion test results show that corrosion current density (3.17 A/cm2 × 10−6) of AA20240-4 wt% B4C/SiC hybrid nanocomposite sample was 46.12 A/cm2 × 10−6 (lower than current density of AA2024 sample). The corrosion current rate of AA2024 alloy was almost 14 times higher than AA2024-4 wt% of B4C/SiC hybrid nanocomposites. Mechanical tests showed that the hardness value of hybrid nanocomposites increases as increased reinforcement content and AA2024-5 wt% B4C/SiC hybrid nanocomposite has a maximum hardness of 179.4 HB.

Similar content being viewed by others

Data Availability

All data obtained in the conduct of this study are presented in the results section of the article. No other data is available.

Code Availability

Not applicable.

References

Alwahib AA, Muttlak WH, Mahdi BS, Mohammed AZ (2020) Corrosion resistance enhancement by laser and reduced graphene oxide-based nano-silver for 1050 aluminum alloy. Surf Interfaces 20:100557. https://doi.org/10.1016/j.surfin.2020.100557

Çevik ZA, Karabacak AH, Kök M, et al (2021) The effect of machining processes on the physical and surface characteristics of AA2024-B4C-SiC hybrid nanocomposites fabricated by hot pressing method. J Compos Mater 55:2657–2671. https://doi.org/10.1177/0021998321996419

Varol T, Canakci A (2015) The effect of type and ratio of reinforcement on the synthesis and characterization Cu-based nanocomposites by flake powder metallurgy. J Alloys Compd 649:1066–1074. https://doi.org/10.1016/j.jallcom.2015.07.008

Teng X, Chen W, Huo D, et al (2018) Comparison of cutting mechanism when machining micro and nano-particles reinforced SiC/Al metal matrix composites. Compos Struct 203:636–647. https://doi.org/10.1016/j.compstruct.2018.07.076

Shaat M, Fathy A, Wagih A (2020) Correlation between grain boundary evolution and mechanical properties of ultrafine-grained metals. Mech Mater 143:103321. https://doi.org/10.1016/j.mechmat.2020.103321

Mohammadi S, Montazeri A, Urbassek HM (2020) Geometrical aspects of nanofillers influence the tribological performance of Al-based nanocomposites. Wear 444–445:203117. https://doi.org/10.1016/j.wear.2019.203117

Carreno-Gallardo C, Mendoza-Duarte JM, Lopez-Melendez C et al (2015) Evaluation of mechanical properties of aluminum alloy (Al-2024) reinforced with carbon-coated silver nanoparticles (AgCNP) metal matrix composites. Microsc Microanal 21:1041–1042. https://doi.org/10.1017/s1431927615006005

Khdair AI, Fathy A (2020) Enhanced strength and ductility of Al-SiC nanocomposites synthesized by accumulative roll bonding. J Mater Res Technol 9:478–489. https://doi.org/10.1016/j.jmrt.2019.10.077

Wagih A, Fathy A (2018) Improving compressibility and thermal properties of Al–Al2O3 nanocomposites using Mg particles. J Mater Sci 53:11393–11402. https://doi.org/10.1007/s10853-018-2422-1

Nosko M, Štepánek M, Zifčák P, et al (2019) Solid-state joining of powder metallurgy Al-Al 2 O 3 nanocomposites via friction-stir welding: Effects of powder particle size on the weldability, microstructure, and mechanical property. Mater Sci Eng A 754:190–204. https://doi.org/10.1016/j.msea.2019.03.074

Wagih A, Fathy A (2016) Experimental investigation and FE simulation of nano-indentation on Al-Al2O3 nanocomposites. Adv Powder Technol 27:403–410. https://doi.org/10.1016/j.apt.2016.01.021

Zhang L, Wang Z, Li Q, et al (2018) Microtopography and mechanical properties of vacuum hot pressing Al/B4C composites. Ceram Int 44:3048–3055. https://doi.org/10.1016/j.ceramint.2017.11.065

Xie Y, Huang Y, Wang F, et al (2020) Deformation-driven metallurgy of SiC nanoparticle reinforced aluminum matrix nanocomposites. J Alloys Compd 823:153741. https://doi.org/10.1016/j.jallcom.2020.153741

Pang X, Xian Y, Wang W, Zhang P (2018) Tensile properties and strengthening effects of 6061Al/12 wt%B4C composites reinforced with nano-Al2O3 particles. J Alloys Compd 768:476–484. https://doi.org/10.1016/j.jallcom.2018.07.072

Reddy MP, Himyan MA, Ubaid F, et al (2018) Enhancing thermal and mechanical response of aluminum using nanolength scale TiC ceramic reinforcement. Ceram Int 44:9247–9254. https://doi.org/10.1016/j.ceramint.2018.02.135

Huang H, Fan G, Tan Z, et al (2017) Superplastic behavior of carbon nanotube reinforced aluminum composites fabricated by flake powder metallurgy. Mater Sci Eng A 699:55–61. https://doi.org/10.1016/j.msea.2017.05.074

Karabacak AH, Çanakçı A, Erdemir F, et al (2020) Effect of different reinforcement on the microstructure and mechanical properties of AA2024-based metal matrix nanocomposites. Int J Mater Res 111:416–423. https://doi.org/10.3139/146.111901

Sadoun AM, Mohammed MM, Fathy A, El-Kady OA (2020) Effect of Al2O3 addition on hardness and wear behavior of Cu-Al2O3 electro-less coated Ag nanocomposite. J Mater Res Technol 9:5024–5033. https://doi.org/10.1016/j.jmrt.2020.03.020

Zhang W, Yamashita S, Kita H (2021) A study of B4C-SiC composite for self-lubrication. J Am Ceram Soc 104:2325–2336. https://doi.org/10.1111/JACE.17584

Seetharam R, Subbu SK, Davidson MJ (2017) Hot workability and densification behavior of sintered powder metallurgy Al-B4C preforms during upsetting. J Manuf Process 28:309–318. https://doi.org/10.1016/j.jmapro.2017.06.012

Kumar SS, Erdemir F, Varol T, et al (2020) Investigation of WEDM process parameters of Al–SiC–B4C composites using response surface methodology. Int J Light Mater Manuf 3:127–135. https://doi.org/10.1016/j.ijlmm.2019.09.003

Bahmani E, Abouei V, Shajari Y et al (2018) Investigation on microstructure, wear behavior and microhardness of Al–Si/SiC nanocomposite. Surf Eng Appl Electrochem 54:350–358. https://doi.org/10.3103/S1068375518040038

Singh J, Chauhan A (2016) Characterization of hybrid aluminum matrix composites for advanced applications - A review. J Mater Res Technol 5:159–169

Toptan F, Alves AC, Kerti I, et al (2013) Corrosion and tribocorrosion behaviour of Al-Si-Cu-Mg alloy and its composites reinforced with B4C particles in 0.05 M NaCl solution. Wear 306:27–35. https://doi.org/10.1016/j.wear.2013.06.026

Katkar VA, Gunasekaran G, Rao AG, Koli PM (2011) Effect of the reinforced boron carbide particulate content of AA6061 alloy on formation of the passive film in seawater. Corros Sci 53:2700–2712. https://doi.org/10.1016/j.corsci.2011.04.023

Li YL, Wang WX, Chen HS et al (2016) Corrosion behavior of B4C/6061Al neutron absorber composite in different H3BO3 concentration solutions. Acta Metall Sin (Eng Lett) 29:1037–1046. https://doi.org/10.1007/s40195-016-0474-2

Ghavidel N, Allahkaram SR, Naderi R et al (2020) Corrosion and wear behavior of an electroless Ni-P/nano-SiC coating on AZ31 Mg alloy obtained through environmentally-friendly conversion coating. Surf Coat Technol 382:125156. https://doi.org/10.1016/j.surfcoat.2019.125156

Canakcı A, Ozkaya S, Erdemir F, et al (2020) Effects of Fe–Al intermetallic compounds on the wear and corrosion performances of AA2024/316L SS metal/metal composites. J Alloys Compd 845:156236. https://doi.org/10.1016/j.jallcom.2020.156236

Güler O, Cuvalci H, Canakci A, Celebi M (2017) The effect of nano graphite particle content on the wear behaviour of ZA27 based hybrid composites. Adv Compos Lett 26:30–36. https://doi.org/10.1177/096369351702600201

Dalmis R, Cuvalci H, Canakci A, Guler O (2017) Effect of nano-sized B4C addition on the mechanical properties of ZA27 composites. J Wuhan Univ Technol Mater Sci Ed 32:747–752. https://doi.org/10.1007/s11595-017-1662-2

Raj R, Thakur DG (2016) Qualitative and quantitative assessment of microstructure in Al-B4C metal matrix composite processed by modified stir casting technique. Arch Civ Mech Eng 16:949–960. https://doi.org/10.1016/j.acme.2016.07.004

Bhatt J, Balachander N, Shekher S, et al (2012) Synthesis of nanostructured Al-Mg-SiO2 metal matrix composites using high energy ball milling and spark plasma sintering. J Alloys Compd 536:S35–S40. https://doi.org/10.1016/j.jallcom.2011.12.062

Yalçın ED, Çanakçı A, Erdemir F et al (2019) Enhancement of wear and corrosion resistance of ZA27/nanographene composites produced by powder metallurgy. Arab J Sci Eng 44:1437–1445. https://doi.org/10.1007/s13369-018-3582-7

Canakci A, Varol T, Cuvalci H, et al (2015) Development and characterization of bronze-Cr-Ni composites produced by powder metallurgy. Sci Eng Compos Mater 22:425–432. https://doi.org/10.1515/secm-2013-0262

Sadoun AM, Fathy A, Abu-Oqail A, et al (2020) Structural, mechanical and tribological properties of Cu–ZrO2/GNPs hybrid nanocomposites. Ceram Int 46:7586–7594. https://doi.org/10.1016/j.ceramint.2019.11.258

Abd-Elwahed MS, Meselhy AF (2020) Experimental investigation on the mechanical, structural and thermal properties of Cu–ZrO2 nanocomposites hybridized by graphene nanoplatelets. Ceram Int 46:9198–9206. https://doi.org/10.1016/j.ceramint.2019.12.172

Abu-Oqail A, Wagih A, Fathy A, et al (2019) Effect of high energy ball milling on strengthening of Cu-ZrO2 nanocomposites. Ceram Int 45:5866–5875. https://doi.org/10.1016/j.ceramint.2018.12.053

Fathy A, Wagih A, Abu-Oqail A (2019) Effect of ZrO2 content on properties of Cu-ZrO2 nanocomposites synthesized by optimized high energy ball milling. Ceram Int 45:2319–2329. https://doi.org/10.1016/j.ceramint.2018.10.147

Wagih A, Fathy A, Kabeel AM (2018) Optimum milling parameters for production of highly uniform metal-matrix nanocomposites with improved mechanical properties. Adv Powder Technol 29:2527–2537. https://doi.org/10.1016/j.apt.2018.07.004

Ramezanalizadeh H (2020) Fabrication and characterization of an Al-based nanocomposite with high specific strength and good elongation using large amount CMA nanoparticles. J Alloys Compd 822:153667. https://doi.org/10.1016/j.jallcom.2020.153667

Dhar S, Jena A, Patnaik SC, et al (2020) A study on microstructure and mechanical properties of aluminium matrix composites with micro-sized iron fillers produced by powder metallurgy route. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.03.733

Charan Nayak K, Kumar Pandey A, Date PP (2020) Mechanical and physical characterization of powder metallurgy based aluminium metal matrix hybrid composite. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.03.134

Sadoun AM, Fathy A (2019) Experimental study on tribological properties of Cu–Al2O3 nanocomposite hybridized by graphene nanoplatelets. Ceram Int 45:24784–24792. https://doi.org/10.1016/j.ceramint.2019.08.220

Baradeswaran A, Elaya Perumal A (2014) Study on mechanical and wear properties of Al 7075/Al2O 3/graphite hybrid composites. Compos Part B Eng 56:464–471. https://doi.org/10.1016/j.compositesb.2013.08.013

Jin Y, Xia N, Gerhardt RA (2016) Enhanced dielectric properties of polymer matrix composites with BaTiO3 and MWCNT hybrid fillers using simple phase separation. Nano Energy 30:407–416. https://doi.org/10.1016/j.nanoen.2016.10.033

Nasr Isfahani MJ, Payami F, Asadabad MA, Shokri AA (2019) Investigation of the effect of boron carbide nanoparticles on the structural, electrical and mechanical properties of Al-B4C nanocomposites. J Alloys Compd 797:1348–1358. https://doi.org/10.1016/j.jallcom.2019.05.188

Sadoun AM, Mohammed MM, Elsayed EM, et al (2020) Effect of nano Al2O3 coated Ag addition on the corrosion resistance and electrochemical behavior of Cu-Al2O3 nanocomposites. J Mater Res Technol 9:4485–4493. https://doi.org/10.1016/j.jmrt.2020.02.076

Halil K, Ismail OI, Sibel D, Ramazan Çi (2019) Wear and mechanical properties of Al6061/SiC/B4C hybrid composites produced with powder metallurgy. J Mater Res Technol 8:5348–5361. https://doi.org/10.1016/j.jmrt.2019.09.002

Wu S, Nakae H (1999) Nucleation effect of alumina in Al-Si/Al2O3 composites. J Mater Sci Lett 18:321–323. https://doi.org/10.1023/A:1006643609938

Aravind M, Yu P, Yau MY, Ng DHL (2004) Formation of Al2Cu and AlCu intermetallics in Al(Cu) alloy matrix composites by reaction sintering. Mater Sci Eng A 380:384–393. https://doi.org/10.1016/j.msea.2004.04.013

Gao Z, Yang H, Feng J, et al (2020) Flux-free diffusion joining of SiCp/6063 al matrix composites using liquid gallium with nano-copper particles in atmosphere environment. Nanomaterials 10. https://doi.org/10.3390/NANO10030437/NANOMATERIALS_10_00437_PDF.PDF

Chen J, Lai YS, Wang YW, Kao CR (2011) Investigation of growth behavior of Al-Cu intermetallic compounds in Cu wire bonding. Microelectron Reliab 51:125–129. https://doi.org/10.1016/j.microrel.2010.09.034

Arab M, Azadi M, mirzaee O (2020) Effects of manufacturing parameters on the corrosion behavior of Al–B4C nanocomposites. Mater Chem Phys 253:123259. https://doi.org/10.1016/J.MATCHEMPHYS.2020.123259

Baradeswaran A, Vettivel SC, Elaya Perumal A, et al (2014) Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater Des 63:620–632. https://doi.org/10.1016/j.matdes.2014.06.054

Liu ZY, Xiao BL, Wang WG, Ma ZY (2017) Modelling of carbon nanotube dispersion and strengthening mechanisms in Al matrix composites prepared by high energy ball milling-powder metallurgy method. Compos Part A Appl Sci Manuf 94:189–198. https://doi.org/10.1016/j.compositesa.2016.11.029

Rajkumar K, Aravindan S (2011) Tribological performance of microwave sintered copperTiCgraphite hybrid composites. Tribol Int 44:347–358. https://doi.org/10.1016/j.triboint.2010.11.008

Rahimian M, Parvin N, Ehsani N (2010) Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy. Mater Sci Eng A 527:1031–1038. https://doi.org/10.1016/j.msea.2009.09.034

Dinaharan I, Balakrishnan M, David Raja Selvam J, Akinlabi ET (2019) Microstructural characterization and tensile behavior of friction stir processed AA6061/Al2Cu cast aluminum matrix composites. J Alloys Compd 781:270–279. https://doi.org/10.1016/j.jallcom.2018.12.091

Mishra AK, Balasubramaniam R, Tiwari S (2007) Corrosion inhibition of 6061-SiC by rare earth chlorides. Anti-Corros Methods Mater 54:37–46. https://doi.org/10.1108/00035590710717384

Güler O, Çelebı M, Dalmış R, et al (2020) Novel ZA27/B4C/graphite hybrid nanocomposite-bearing materials with enhanced wear and corrosion resistance. Metall Mater Trans A: 1–15. https://doi.org/10.1007/s11661-020-05863-5

Erdemir F, Canakci A, Varol T, Ozkaya S (2015) Corrosion and wear behavior of functionally graded Al2024/SiC composites produced by hot pressing and consolidation. J Alloys Compd 644:589–596. https://doi.org/10.1016/j.jallcom.2015.04.216

Author information

Authors and Affiliations

Contributions

Abdullah Hasan Karabacak: İnvestigation, Writing – original draft, software. Aykut Çanakçı: Supervisor, Writing. Fatih Erdemir: Writing. Serdar Özkaya: İnvestigation. Müslim Çelebi: İnvestigation.

Corresponding author

Ethics declarations

Conflicts of Interest/Competing interests

All the authors of the present article declare that they have no conflict of interest.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karabacak, A.H., Çanakçı, A., Erdemir, F. et al. Corrosion and Mechanical Properties of Novel AA2024 Matrix Hybrid Nanocomposites Reinforced with B4C and SiC Particles. Silicon 14, 8567–8579 (2022). https://doi.org/10.1007/s12633-021-01582-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01582-7