Abstract

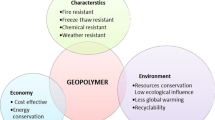

This research aims to study the behavior of silica based geopolymeric material (22–28%Si) from granitic waste. Granitic waste in powder form was used as main precursor in combination of activating alkaline-solution (18% Na2SiO3, 7% NaOH and 75% distilled water). The ratio between Na2SiO3 and NaOH was kept constant (2.57) in all experiments to achieve appropriate geopolymerization but solid to liquid ratio was varied. Five different compositions of geopolymeric material were prepared with varying proportions of granite waste in the range of 70–78%, combined-alkaline-solution in range of 28–20% and 2% water. Curing of the samples was done in a heating oven at 70 °C for 24 h. After that samples were de-moulded and placed in a heating furnace for further curing at 220 °C for 2 h. After curing, compressive strength, density (bulk, apparent and true) and porosity (open, close and total) were measured. Phase analysis, degree of geopolymerization and microstructural analysis were evaluated by XRF (X-ray Fluorescence), FTIR (Fourier Transform Infrared Spectroscopy) and SEM (Scanning Electron Microscopy), respectively. XRF analysis revealed 28.38% Si and 5.96% Al which are the main constituents for the synthesis of geopolymer. Maximum achieved compressive strength was 22 MPa with minimum porosity of 19.487% in 78% granite based geopolymer. Minimum bulk density of 1.441 g/cm3 was achieved using 70% granite waste. FTIR results confirmed geopolymerization and optimized composition in the resultant samples which is 78% granite and 20% combined-alkaline-solution. Further, SEM results revealed most homogenous and dense structure in the same composition. The durability of the geopolymeric samples was evaluated by water absorption index. Maximum water absorption index of 3.09 was found in 72% granite based sample having 26.79% Si while minimum 2.018 in 78% granite based geopolymeric material having 22.97% Si. Positive compositional effect on various construction properties has been achieved in this study.

Similar content being viewed by others

Data Availability

All data and information related to current study is only available in this manuscript. There is no other source to access the data of this research.

References

Pacheco-Torgal F, Labrincha JA (2013) The future of construction materials research and the seventh UN millennium development goal: a few insights. Constr Build Mater 40:729–737

Karim MR, Zain MFM, Jamil M, Lai FC, Islam MN (2011) Use of wastes in construction industries as an energy saving approach. Energy Procedia 12:915–919

Rashid M, Haq EU, Yousaf S, Javed M, Nadeem M, Aziz U, Abbas AQ (2020) Light weight low thermal conductive fly ash foams through microwave irradiation for insulative, agricultural and self-healing purposes, mater, today Proc

Haq EU, Majeed MU, Nadeem M, Ahmed F, Zain-Ul-Abdein M, Mughal K, Abbas AQ, Hayat Q (2020) Reinforcement of silica particles in bentonite clay based porous Geopolymeric material, silicon. https://doi.org/10.1007/s12633-020-00633-9

Nadeem M, Zain-ul-abdein M, Ahmed F, Haq EU, Khan WA, Shamsah SMI (n.d.) Experimental and theoretical investigation of thermal properties of natural soil based geopolymer composites, pp 1024–1037

Nadeem M, Haq EU, Ahmed F, Rafiq MA, Awan GH, Zain-ul-abdein M (2020) Effect of microwave curing on the construction properties of natural soil based geopolymer foam. Constr Build Mater 230:117074. https://doi.org/10.1016/j.conbuildmat.2019.117074

Fine LJ, Rosenstock L (2005) Cardiovascular disorders, in: Textb. Clin. Occup. Environ. Med., Elsevier, pp 549–563

Zaidi SFA, Haq EU, Nur K, Ejaz N, Anis-ur-Rehman M, Zubair M, Naveed M (2017) Synthesis & characterization of natural soil based inorganic polymer foam for thermal insulations. Constr Build Mater 157:994–1000. https://doi.org/10.1016/j.conbuildmat.2017.09.112

Silva G, Kim S, Aguilar R, Nakamatsu J (2020) Natural fibers as reinforcement additives for geopolymers--a review of potential eco-friendly applications to the construction industry. Sustain Mater Technol 23:e00132

Korniejenko K, Lin W-T, Šimonová H (2020) Mechanical properties of short polymer fiber-reinforced geopolymer composites. J Compos Sci 4:128

Bumanis G, Vitola L, Pundiene I, Sinka M, Bajare D (2020) Gypsum, Geopolymers, and starch—alternative binders for bio-based building materials: a review and life-cycle assessment. Sustainability. 12:5666

M.R.A. Karim, E.U. Haq, M.A. Hussain, K.I. Khan, M. Nadeem, M. Atif, A.U. Haq, M. Naveed, M.M. Alam, Experimental evaluation of sustainable geopolymer mortars developed from loam natural soil, J Asian Archit Build Eng 0 (2020) 1–10. https://doi.org/10.1080/13467581.2020.1773829, 19

Djobo JNY, Elimbi A, Tchakouté HK, Kumar S (2016) Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr Build Mater 124:606–614

E. ul Haq, Padmanabhan SK, Licciulli A (2014) Synthesis and characteristics of fly ash and bottom ash based geopolymers–a comparative study. Ceram Int 40:2965–2971. https://doi.org/10.1016/j.ceramint.2013.10.012

Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M (2018) One-part alkali-activated materials: a review. Cem Concr Res 103:21–34. https://doi.org/10.1016/j.cemconres.2017.10.001

Davidovits J (1987) Ancient and modern concretes: what is the real difference? Concr Int 9:23–29

Zhang H, Ji T, Lin X (2019) Pullout behavior of steel fibers with different shapes from ultra-high performance concrete (UHPC) prepared with granite powder under different curing conditions. Constr Build Mater 211:688–702

Singh S, Nagar R, Agrawal V (2016) A review on properties of sustainable concrete using granite dust as replacement for river sand. J Clean Prod 126:74–87

Tchadjié LN, Djobo JNY, Ranjbar N, Tchakouté HK, Kenne BBD, Elimbi A, Njopwouo D (2016) Potential of using granite waste as raw material for geopolymer synthesis. Ceram Int 42:3046–3055

Sharma NK, Kumar P, Kumar S, Thomas BS, Gupta RC (2017) Properties of concrete containing polished granite waste as partial substitution of coarse aggregate. Constr Build Mater 151:158–163

Li H, Huang F, Cheng G, Xie Y, Tan Y, Li L, Yi Z (2016) Effect of granite dust on mechanical and some durability properties of manufactured sand concrete. Constr Build Mater 109:41–46

Akbulut H, Gürer C, Çetin S, Elmaci A (2012) Investigation of using granite sludge as filler in bituminous hot mixtures. Constr Build Mater 36:430–436

Medina G, del Bosque IFS, Frias M, de Rojas MIS, Medina C (2018) Durability of new recycled granite quarry dust-bearing cements. Constr Build Mater 187:414–425

Ramos T, Matos AM, Schmidt B, Rio J, Sousa-Coutinho J (2013) Granitic quarry sludge waste in mortar: effect on strength and durability. Constr Build Mater 47:1001–1009

Hojamberdiev M, Eminov A, Xu Y (2011) Utilization of muscovite granite waste in the manufacture of ceramic tiles. Ceram Int 37:871–876

Hlaváček P, Šmilauer V, Škvára F, Kopecký L, Šulc R (2015) Inorganic foams made from alkali-activated fly ash: mechanical, chemical and physical properties. J Eur Ceram Soc 35:703–709. https://doi.org/10.1016/j.jeurceramsoc.2014.08.024

Zha X, Dassekpo JBM (2018) Green synthesis and structural characterization of completely decomposed granite (CDG) based geopolymer. AIP Conf Proc 2030. https://doi.org/10.1063/1.5066829

Eroshkina N, Korovkin M (2016) The effect of the mixture composition and curing conditions on the properties of the Geopolymer binder based on dust crushing of the granite. Procedia Eng 150:1605–1609. https://doi.org/10.1016/j.proeng.2016.07.137

Dassekpo J-BM, Zha X, Zhan J (2017) Compressive strength performance of geopolymer paste derived from completely decomposed granite (CDG) and partial fly ash replacement. Constr Build Mater 138:195–203

Frey B, Rieder SR, Brunner I, Plötze M, Koetzsch S, Lapanje A, Brandl H, Furrer G (2010) Weathering-associated bacteria from the Damma glacier forefield: physiological capabilities and impact on granite dissolution. Appl Environ Microbiol 76:4788–4796

Weng KSÆL (2007) Dissolution processes , hydrolysis and condensation reactions during geopolymer synthesis: part II . High Si / Al ratio systems, pp 3007–3014. https://doi.org/10.1007/s10853-006-0818-9

Nyale SM, Babajide OO, Birch GD, Böke N, Petrik LF (2013) Synthesis and characterization of coal Fly ash-based foamed Geopolymer. Procedia Environ, Sci. https://doi.org/10.1016/j.proenv.2013.04.098

Ducman V, Korat L (2016) Characterization of geopolymer fly-ash based foams obtained with the addition of Al powder or H2O2 as foaming agents. Mater Charact 113:207–213. https://doi.org/10.1016/j.matchar.2016.01.019

Abdullah MMAB, Kamarudin H, Binhussain M, Nizar K, Yahya Z, Razak R (2012) Fly ash-based Geopolymer lightweight concrete using foaming agent. Int J Mol Sci 13:7186–7198

Haq EU, Padmanabhan SK, Zubair M, Ali L, Licciulli A (2016) Intumescence behaviour of bottom ash based geopolymer mortar through microwave irradiation – as affected by alkali activation. Constr Build Mater 126:951–956. https://doi.org/10.1016/j.conbuildmat.2016.08.135

Bai C, Franchin G, Elsayed H, Conte A, Colombo P (2016) High strength metakaolin-based geopolymer foams with variable macroporous structure. J Eur Ceram Soc 36:4243–4249. https://doi.org/10.1016/j.jeurceramsoc.2016.06.045

He P, Wang M, Fu S, Jia D, Yan S, Yuan J, Xu J, Wang P, Zhou Y (2016) Effects of Si/Al ratio on the structure and properties of metakaolin based geopolymer. Ceram Int 42:14416–14422. https://doi.org/10.1016/j.ceramint.2016.06.033

Kränzlein E, Pöllmann H, Krcmar W (2018) Metal powders as foaming agents in fly ash based geopolymer synthesis and their impact on the structure depending on the Na/Al ratio. Cem Concr Compos 90:161–168

Lee B, Kim G, Kim R, Cho B, Lee S, Chon C-M (2017) Strength development properties of geopolymer paste and mortar with respect to amorphous Si/Al ratio of fly ash. Constr Build Mater 151:512–519

Prud’homme E, Michaud P, Joussein E, Peyratout C, Smith A, Rossignol S (2011) In situ inorganic foams prepared from various clays at low temperature. Appl Clay Sci 51:15–22. https://doi.org/10.1016/j.clay.2010.10.016

Haq EU, Padmanabhan SK, Licciulli A (2014) In-situ carbonation of alkali activated fly ash geopolymer. Constr Build Mater 66:781–786

Haq EU, Padmanabhan SK, Licciulli A (2013) Synthesis and characteristics of fl y ash and bottom ash based geopolymers – a comparative study. Ceram Int 40:2965–2971. https://doi.org/10.1016/j.ceramint.2013.10.012

Kubba Z, Huseien GF, Sam ARM, Shah KW, Asaad MA, Ismail M, Tahir MM, Mirza J (2018) Impact of curing temperatures and alkaline activators on compressive strength and porosity of ternary blended geopolymer mortars. Case Stud Constr Mater 9:e00205

Izquierdo M, Querol X, Phillipart C, Antenucci D, Towler M (2010) The role of open and closed curing conditions on the leaching properties of fly ash-slag-based geopolymers. J Hazard Mater 176:623–628

Abdollahnejad Z, Pacheco-Torgal F, Félix T, Tahri W, Barroso Aguiar J (2015) Mix design, properties and cost analysis of fly ash-based geopolymer foam. Constr Build Mater 80:18–30. https://doi.org/10.1016/j.conbuildmat.2015.01.063

Mermerdas K, Manguri S, Nassani DE, Oleiwi SM (2017) Effect of aggregate properties on the mechanical and absorption characteristics of geopolymer mortar. Eng Sci Technol an Int J 20:1642–1652

Gingos GS (2011) Effect of PFA on strength and water absorption of mortar. J Civ Eng Sci Technol 2:7–11

Zhang M, Zhao M, Zhang G, Sietins JM, Granados-Focil S, Pepi MS, Xu Y, Tao M (2018) Reaction kinetics of red mud-fly ash based geopolymers: effects of curing temperature on chemical bonding, porosity, and mechanical strength. Cem Concr Compos 93:175–185

Duxson P, Fernández-Jiménez A, Provis JL, Lukey GC, Palomo A, van Deventer JSJ (2007) Geopolymer technology: the current state of the art. J Mater Sci 42:2917–2933. https://doi.org/10.1007/s10853-006-0637-z

Acknowledgements

All the authors of this work acknowledge MME (Metallurgical and Materials Engineering) department of University of Engineering and Technology (UET) Lahore, Pakistan for providing all basic facilities to complete this research.

Author information

Authors and Affiliations

Contributions

All authors have participated in conception and design, analysis and interpretation of the data.

Muhammad Nadeem: Data curation, writing original draft, Software, Conceptualization, Validation.

Samina ilyas: Conceptualization, Methodology, Software, Writing.

Ehsan Ul Haq: Supervision, Visualization, Investigation.

Furqan Ahmed: Result analysis, Review & editing.

Muhammad Zain-ul-Abdein: Review & editing.

Muhammad Ramzan Abdul Karim: Characterization, testing.

Syed Farrukh Alam Zaidi: Review & editing.

Corresponding authors

Ethics declarations

Declaration of Competing Interest

The authors have no affiliation with any organization with a direct or indirect financial interest in the subject matter discussed in the manuscript.

Consent to Participate

Not Applicable.

Consent for Publication

Not Applicable.

Conflict of Interest

There is no conflict of interest of any author.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nadeem, M., Ilyas, S., Haq, E.U. et al. Improved Water Retention and Positive Behavior of Silica Based Geopolymer Utilizing Granite Powder. Silicon 14, 2337–2349 (2022). https://doi.org/10.1007/s12633-021-01047-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01047-x