Abstract

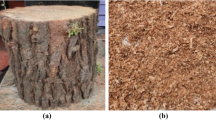

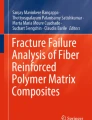

Over the past decades the need for eco-friendly, non-toxic and biodegradable material is growing significantly. Natural fiber polymer composites have become the prior choice for many applications, as the natural fiber polymer composites are economical and eco-friendly materials in contrast with synthetic fiber reinforced composites. In the current study arhar fiber is used as a reinforcing material. Arhar fiber epoxy composites are fabricated using the hand lay-up technique. The materials were tested for weight gain in different environments (saline water, mineral water and subzero temperature condition). The composite samples immersed in the different environments were tested for tensile strength. It is observed that weight gain is more in mineral water and saline water, minimum weight gain is observed in subzero condition. Maximum tensile strength is observed in 10%fiber content samples. Strength depreciation ismore in samples immersed in the saline water environment.

Similar content being viewed by others

References

Seki Y et al (2010) Effect of the low and radio frequency oxygen plasma treatment of jute fiber on mechanical properties of jute fiber/polyester composite. Fibers Polym 11(8):1159–1164

Khanam P. N et al (2011) Tensile, flexural and chemical resistance properties of sisal fiber reinforced polymer composites: Effect of fiber surface treatment. J Polym Environ 19(1):115–119

Zhang Z. et al (2014) Erratum to: mechanical and thermal properties of short-coir-fiber-reinforced natural rubber/polyethylene composites. Mech Compos Mater 50(4):543–543

Yuan FP et al (2013) Reinforcing effects of modified Kevlarfiber on the mechanical properties of wood-flour/polypropylene composites. J For Res 24(1):149–153

Song Y et al (2013) Mechanical properties of poly (lactic acid)/hemp fiber composite prepared by a novel method. J Polym Environ 21(4):1117–1127

Liu H et al (2009) Preparation and properties of banana fiber-reinforced composites based on high-density polyethylene (HDPE)/Nylon-6 blends. Bio Res Technol 100(23):6088– 6097

Malkapuram et al (2008) Recent development in natural fiber reinforced polypropylene composites. J Reinf Plast Compos 28(10):1169–1189

Wambua et al (2003) Natural fibers: can they replace glass in fiber reinforced plastics?. Compos Sci Technol 63:1259–1264

Ilanko A. K., Vijayaraghavan S (2016) Wear behavior of asbestos-free eco-friendly composites for automobile brake materials. Friction 4(2):144–152

Satapathy et al (2009) A study on processing, characterization and erosion behavior of fish (Labeo-rohita) scale filled epoxy matrix composites. Mater Des 30(7):2359–2371

Ku H et al (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B: Eng 42(4):856–873

Joseph K et al (1995) Effect of aging on the physical and mechanical properties of sisal-fiber-reinforced polyethylene composites. Compos Sci Technol 53(1):99–110

Gu H et al (2009) Tensile behaviors of the coir fiber and related composites after NaOH treatment. Mater Des 30(9):3931–3934

Xie Y et al (2010) Saline coupling agents used for natural fiber/polymer composites: A review. Compos Part A: Appl Sci Manuf 41(7):806–819

Keener TJ et al (2004) Maleated coupling agents for natural fiber composites. Appl Sci Manuf 35(3):357–362

Ku H et al (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos Part B: Eng 42(4):856–873

Mathew A. et al (2011) Moisture absorption behavior and its impact on the mechanical properties of cellulose whiskers-based poly vinyl acetate Nano composites. Polym Eng Sci 51(11):2136–2142

Raghavendra G et al (2015) Moisture absorption behavior and its effect on the mechanical properties of jute-reinforced epoxy composite. Polymer Composites. doi:10.1002/pc.23610: 1-7

Patel B. et al (2012) Environmental effect of water absorption and flexural strength of red mud filled jute fiber/polymer composite. Int J Eng Sci Technol 4(4):49–59

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prakash, M.O., Raghavendra, G., Panchal, M. et al. Influence of Distinct Environment on the Mechanical Characteristics of Arhar Fiber Polymer Composites. Silicon 10, 825–830 (2018). https://doi.org/10.1007/s12633-016-9536-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-016-9536-3