Abstract

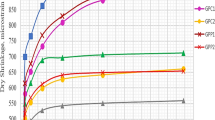

A metakaolin (Mk)-based geopolymer cement from Tunisian Mk mixed with different amounts of silica fume (SiO2/Al2O3 molar ratio varying between 3.61 and 4.09) and sodium hydroxide (10 M) and without any alkali silicate solution, is developed in this work. After the samples were cured at room temperature under air for 28 d, they were analyzed by X-ray diffraction (XRD), Fourier transform infrared (FTIR) spectroscopy, environmental scanning electron microscopy, mercury intrusion porosimetry, 27Al and 29Si nuclear magnetic resonance (NMR) spectroscopy, and compression testing to establish the relationship between microstructure and compressive strength. The XRD, FTIR, and 27Al and 29Si NMR analyses showed that the use of silica fume instead of alkali silicate solutions was feasible for manufacturing geopolymer cement. The Mk-based geopolymer with a silica fume content of 6wt% (compared with those with 2% and 10%), corresponding to an SiO2/Al2O3 molar ratio of 3.84, resulted in the highest compressive strength, which was explained on the basis of its high compactness with the smallest porosity. Silica fume improved the compressive strength by filling interstitial voids of the microstructure because of its fine particle size. In addition, an increase in the SiO2/Al2O3 molar ratio, which is controlled by the addition of silica fume, to 4.09 led to a geopolymer with low compressive strength, accompanied by microstructures with high porosity. This high porosity, which is responsible for weaknesses in the specimen, is related to the amount of unreacted silica fume.

Similar content being viewed by others

References

M. Mustafa, A. Bakri, H. Mohammed, H. Kamarudin, I.K. Niza, and Y. Zarina, Review on fly ash-based geopolymer concrete without Portland Cement, J. Eng. Technol. Res., 3(2011), No. 1, p. 1.

M.A. Villaquirán-caicedo, R.M. de Gutiérrez, S. Sulekar, C. Davis, and J.C. Nino, Thermal properties of novel binary geopolymers based on metakaolin and alternative silica sources, Appl. Clay Sci., 118(2015), p. 276.

J. Davidovits, Properties of geopolymer cements, [in] First International Conference on Alkaline Cements and Concretes, Kiev, 1994, p. 131.

H.T. Huynh, New generation geopolymers, [in] 2nd French Seminar on Geopolymers, Clermont-Ferrand, 2013.

Y.M. Liew, C.Y. Heah, A.B. Mohd Mustafa, and H. Kamarudin, Structure and properties of clay-based geopolymer cements: A review, Prog. Mater. Sci., 83(2016), p. 595.

P. Zhang, Y.X. Zheng, K.J. Wang, and J.P. Zhang, A review on properties of fresh and hardened geopolymer mortar, Composites Part B, 152(2018), p. 79.

C. Dupuy, A. Gharzouni, N. Texier-Mandoki, X. Bourbon, and S. Rossignol, Thermal resistance of argillite-based alkali-activated materials. Part 1: Effect of calcination processes and alkali cation, Mater. Chem. Phys., 217(2018), p. 323.

M.I. Khan, H.U. Khan, K. Azizli, S. Sufian, Z. Man, A.A. Siyal, N. Muhammad, and M.F. ur Rehman, The pyrolysis kinetics of the conversion of Malaysian kaolin to metakaolin, Appl. Clay Sci., 146(2017), p. 152.

J.S. Geng and Q. Sun, Effects of high temperature treatment on physical-thermal properties of clay, Thermochim. Acta, 666(2018), p. 148.

V. Medri, S. Fabbri, J. Dedecek, Z. Sobalik, Z. Tvaruzkova, and A. Vaccari, Role of the morphology and the dehydroxylation of metakaolins on geopolymerization, Appl. Clay Sci., 50(2010), No. 4, p. 538.

Y.M. Liew, H. Kamarudin, A.M. Mustafa Al Bakri, M. Luqman, I. Khairul Nizar, C.M. Ruzaidi, and C.Y. Heah, Processing and characterization of calcined kaolin cement powder, Constr. Build. Mater., 30(2012), p. 794.

Y.M. Liew, H. Kamarudin, A.M. Mustafa Al Bakri, M. Binhussain, M. Luqman, I. Khairul Nizar, C.M. Ruzaidi, and C.Y. Heah, Influence of solids-to-liquid and activator ratios on calcined kaolin cement powder, Phys. Procedia, 22(2011), p. 312.

C.Y. Heah, H. Kamarudin, A.M. Mustafa Al Bakri, M Bnhussain, M. Luqman, I. Khairul Nizar, C.M. Ruzaidi, and Y.M. Liew, Kaolin-based geopolymers with various NaOH concentrations, Int. J. Miner. Metall. Mater., 20(2013), No. 3, p. 313.

P. De Silva, K. Sagoe-Crenstil, and V. Sirivivatnanon, Kinetics of geopolymerization: Role of Al2O3 and SiO2, Cem. Concr. Res., 37(2007), No. 4, p. 512.

F.N. Okoye, J. Durgaprasad, and N.B. Singh, Effect of silica fume on the mechanical properties of fly ash based-geopolymer concrete, Ceram. Int., 42(2015), No. 2, p. 3000.

D. Dutta, S. Thokchom, P. Ghosh, and S. Ghosh, Effect of silica fume additions on porosity of fly ash geopolymers, J. Eng. Appl. Sci., 5(2010), No. 10, p. 74.

C.S. Poon, S.C. Kou, and L. Lam, Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete, Constr. Build. Mater., 20(2006), No. 10, p. 858.

P. Duan, C.J. Yan, and W. Zhou, Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle, Cem. Concr. Compos., 78(2017), p. 108.

M. Uysal, M.M. Al-mashhadani, Y. Aygörmez, and O. Canpolat, Effect of using colemanite waste and silica fume as partial replacement on the performance of metakaolin-based geopolymer mortars, Constr. Build. Mater., 176(2018), p. 271.

B.A. Latella, D.S. Perera, D. Durce, E.G. Mehrtens, and J. Davis, Mechanical properties of metakaolin-based geopolymers with molar ratios of Si/Al ≈ 2 and Na/Al ≈ 1, J. Mater. Sci., 43(2008), No. 8, p. 2693.

M. Rostami and K. Behfarnia, The effect of silica fume on durability of alkali activated slag concrete, Constr. Build. Mater., 134(2017), p. 262.

D. Panias, I.P. Giannopoulou, and T. Perraki, Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers, Colloids Surf. A, 301(2007), No. 1–3, p. 246.

Z.H. Zhang, X. Yao, H.J. Zheng, and C. Yue, Role of water in the synthesis of calcined kaolin-based geopolymer, Appl. Clay Sci., 43(2009), No. 2, p. 218.

J.G.S. van Jaarsveld and J.S.J. van Deventer, Effect of the alkali metal activator on the properties of fly ash based geopolymers, Ind. Eng. Chem. Res., 38(1999), No. 10, p. 3932.

P.N. Lemougna, A.B. Madi, E. Kamseu, U.C. Melo, M.P. Delplancke, and H. Rahier, Influence of the processing temperature on the compressive strength of Na activated lateritic soil for building applications, Constr. Build. Mater., 65(2014), p. 60.

A.M.M. Al Bakri, H. Kamarudin, M. Bnhussain, J. Liyana, and C.M. Ruzaidi Ghazali, Nano geopolymer for sustainable concrete using fly ash synthesized by high energy ball milling, Appl. Mech. Mater., 313–314(2013), p. 169.

S.A. Bernal, E.D. Rodríguez, R. Mejía de Gutiérrez, M. Gordillo, and J.L. Provis, Mechanical and thermal characterisation of geopolymers based on silicate-activated metakaolin/slag blends, J. Mater. Sci., 46(2011), No. 16, p. 5477.

T. Revathi, R. Jeyalakshmi, and N. P. Rajamane, Study on the role of n-SiO2 incorporation in thermo-mechanical and microstructural properties of ambient cured FA-GGBS geopolymer matrix, Appl. Surf. Sci., 449(2018), p. 322.

C. Kuenzel, L.M. Grover, L. Vandeperre, A.R. Boccaccini, and C.R. Cheeseman, Production of nepheline/quartz ceramics from geopolymer mortars, J. Eur. Ceram. Soc., 33(2013), No. 2, p. 251.

G. Kakali, T. Perraki, S. Tsivilis, and E. Badogiannis, Thermal treatment of kaolin: The effect of mineralogy on the pozzolanic activity, Appl. Clay Sci., 20(2001), No. 1–2, p. 73.

S. Ahmari, X. Ren, V. Toufigh, and L.Y. Zhang, Production of geopolymeric binder from blended waste concrete powder and fly ash, Constr. Build. Mater., 35(2012), p. 718.

W.K.W. Lee and J.S.J. van Deventer, Use of infrared spectroscopy to study geopolymerization of heterogeneous amorphous aluminosilicates, Langmuir, 19(2003), No. 21, p. 8726.

Q. Wan, F. Rao, S.X. Song, D.F. Cholico-González, and N.L. Ortiz, Combination formation in the reinforcement of meta-kaolin geopolymers with quartz sand, Cem. Concr. Compos., 80(2017), p. 115.

K. Gao, K.L. Lin, D.Y. Wang, H.S. Shiu, C.L. Hwang, and T.W. Cheng, Effects of nano-SiO2 on setting time and compressive strength of alkali- activated metakaolin-based geopolymer, Open Civ. Eng. J., 7(2013), p. 84.

W.K.W. Lee and J.S.J. van Deventer, Structural reorganisation of class F fly ash in alkaline silicate solutions, Colloids Surf. A, 211(2002), No. 1, p. 49.

T. Bakharev, Geopolymeric materials prepared using Class F fly ash and elevated temperature curing, Cem. Concr. Res., 35(2005), No. 6, p. 1224.

J. Rocha and J. Klinowski, 29Si and 27Al magic-angle-spinning NMR studies of the thermal transformation of kaolinite, Phys. Chem. Miner., 17(1990), No. 2, p. 179.

P.S. Singh, M. Trigg, I. Burgar, and T. Bastow, Geopolymer formation processes at room temperature studied by 29Si and 27Al MAS-NMR, Mater. Sci. Eng. A, 396(2005), No. 1–2, p. 392.

F. Škvára, L. Kopecký, J. Němeček, and Z. Bittnar, Microstructure of geopolymer materials based on fly ash, Ceram. Silik., 50(2006), No. 4, p. 208.

A. Bourlon, Physico-chimie et Rhéologie de Géopolymères Frais Pour la Cimentation des Puits Pétroliers [Dissertation], Pierre et Marie Curie University, Paris, 2010.

M.A. Soleimani, R. Naghizadeh, A.R. Mirhabibi, and F. Golestanifard, Effect of calcination temperature of the kaolin and molar Na2O/SiO2 activator ratio on physical and microstructural properties of metakaolin based geopolymers, Iran. J. Mater. Sci. Eng., 9(2012), No. 4, p. 43.

P. Chindaprasirt, T. Chareerat, and V. Sirivivatnanon, Workability and strength of coarse high calcium fly ash geopolymer, Cem. Concr. Compos., 29(2007), No. 3, p. 224.

Y.S. Zhang, W. Sun, and Z.J. Li, Composition design and microstructural characterization of calcined kaolin-based geopolymer cement, Appl. Clay Sci., 47(2010), No. 3–4, p. 271.

C.K. Ma, A.Z. Awang, and W. Omar, Structural and material performance of geopolymer concrete: A review, Constr. Build. Mater., 186(2018), p. 90.

T. da S. Rocha, D.P. Dias, F.C.C. França, R.R. de S. Guerra, and L.R. da C. de O. Marques, Metakaolin-based geopolymer mortars with different alkaline activators (Na+ and K+), Constr. Build. Mater., 178(2018), p. 453.

P. Duan, Z.G. Shui, W. Chen, and C.H. Shen, Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete, Constr. Build. Mater., 44(2013), p. 1.

Acknowledgement

The authors are pleased to acknowledge the Tunisian Ministry of Higher Education and Scientific Research for its help in financing internships in France.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nmiri, A., Duc, M., Hamdi, N. et al. Replacement of alkali silicate solution with silica fume in metakaolin-based geopolymers. Int J Miner Metall Mater 26, 555–564 (2019). https://doi.org/10.1007/s12613-019-1764-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1764-2