Abstract

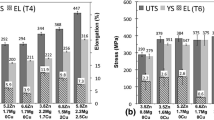

The microstructure and mechanical properties of as-cast A356 (Al–Si) alloy castings were investigated. A356 alloy was cast into three different molds composed of sand, ferrochrome (Fe–Cr) slag, and a mixture of sand and Fe–Cr. A sodium silicate–CO2 process was used to make the necessary molds. Cylindrical-shaped castings were prepared. Cast products with no porosity and a good surface finish were achieved in all of the molds. These castings were evaluated for their metallography, secondary dendrite arm spacing (SDAS), and mechanical properties, including hardness, compression, tensile, and impact properties. Furthermore, the tensile and impact samples were analyzed by fractography. The results show that faster heat transfer in the Fe–Cr slag molds than in either the silica sand or mixed molds led to lower SDAS values with a refined microstructure in the products cast in Fe–Cr slag molds. Consistent and enhanced mechanical properties were observed in the slag mold products than in the castings obtained from either sand or mixed molds. The fracture surface of the slag mold castings shows a dimple fracture morphology with a transgranular fracture nature. However, the fracture surfaces of the sand mold castings display brittle fracture. In conclusion, products cast in Fe–Cr slag molds exhibit an improved surface finish and enhanced mechanical properties compared to those of products cast in sand and mixed molds.

Similar content being viewed by others

References

M. Mansour, Develop a strategic forecast of silica sand based on supply chain decomposition, Int. J. Eng., 9(2015), No. 1, p. 9.

Ziauddin and A. Joshi, Foundry project planning—some pitfalls, Indian Foundry J., 60(2014), No. 2, p. 40.

D.R. Bhimani, J. Pitroda, and J.J. Bhavsar, A study on foundry sand: opportunities for sustainable and economical concrete, Global Res. Anal., 2(2013), No. 1, p. 60.

B.B. Lind, A.M Fällman, and L.B. Larsson, Environmental impact of ferrochrome slag in road construction, Waste Manage., 21(2001), No. 3, p. 255.

K. Kubo and R.D. Pehlke, Thermal properties of molding sands, Trans. Am. Foundrymen's Soc., 93(1985), p. 405.

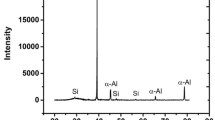

I.N. Murthy and J.B. Rao, Investigations on physical and chemical properties of high silica sand, Fe–Cr slag and blast furnace slag for foundry applications, Procedia Environ. Sci., 35(2016), p. 583.

I.N. Murthy, N.A. Babu, and J.B. Rao, High carbon ferro chrome slag—alternative mould material for foundry industry, Procedia Environ. Sci., 35(2016), p. 597.

W.M. Jiang, Z.T. Fan, D.J. Liu, D.F. Liao, X.P. Dong, and X.M. Zong, Correlation of microstructure with mechanical properties and fracture behavior of A356-T6 aluminum alloy fabricated by expendable pattern shell casting with vacuum and low-pressure, gravity casting and lost foam casting, Mater. Sci. Eng. A, 560(2013), p. 396.

M. Merlin and G.L. Garagnani, Mechanical and microstructural characterization of A356 castings realised with full and empty cores, Metall. Sci. Technol., 27(2009), No. 1, p. 21.

G.K. Sigworth, Fundamentals of solidification in aluminum castings, Int. J. Metalcast., 8(2014), No. 1, p. 7

F. Grosselle, G. Timelli, F. Bonollo, and R. Molina, Correlation between microstructure and mechanical properties of Al–Si diecast engine blocks, Metall. Sci. Technol., 27 (2009), No. 2, p. 2.

Q.G. Wang, Microstructural effects on the tensile and fracture behavior of aluminum casting alloys A356/357, Metall. Mater. Trans. A, 34(2003), No. 12, p. 2887.

W.M. Jiang, Z.T. Fan, and D.J. Liu, Microstructure, tensile properties and fractography of A356 alloy under as-cast and T6 obtained with expendable pattern shell casting process, Trans. Nonferrous Met. Soc. China, 22(2012), Suppl. 1, p. s7.

H. Mae, X. Teng, Y. Bai, and T. Wierzbicki, Comparison of ductile fracture properties of aluminium castings: Sand mold vs. metal mold, Int. J. Solids Struct., 45(2008), No. 5, p. 1430.

Acknowledgments

Authors would thank the DST–Fly Ash unit, New Delhi, India for their financial support (Grant Ref No. FAU/DST/600(52)/2012-13). Thanks to Advance Analytical laboratory, Andhra University, India for the support in SEM–EDS studies. Special thanks to M/s. Jindal Steel & Ferro Alloys Ltd. Kothavalasa, Visakhapatnam, India for the supply of Ferro chrome slag for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Narasimha Murthy, I., Babu Rao, J. Evaluation of the microstructure, secondary dendrite arm spacing, and mechanical properties of Al–Si alloy castings made in sand and Fe–Cr slag molds. Int J Miner Metall Mater 24, 784–793 (2017). https://doi.org/10.1007/s12613-017-1462-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1462-x