Abstract

Aqueous batteries and seawater desalination have received considerable attention in recent years due to their merits as high safety, environmental friendliness and cost-effectiveness. However, the scarcity of highly match electrode materials hinders their development. The exploration of high performance and low cost electrode materials is crucial for their potential applications. Bismuth (Bi), with high energy density and low redox potential, shows perspective in the field of aqueous batteries and seawater desalination, and significant progress has been achieved in the past decades. In this review, the unique properties and synthetic methods of Bi-based electrodes, as well as their applications are comprehensively summarized and discussed. The commonly used preparation methods of Bi-based electrodes, including hydrothermal method, electrodeposition method, etc., are introduced. Then, the applications of the Bi-based composites in aqueous batteries, such as Ni//Bi batteries and water desalination, are summarized. Finally, the challenges and future research direction of Bi-based materials are proposed.

Graphic Abstract

摘要

近年来,水系电池和海水淡化由于其高安全性, 环保性和成本效益而受到广泛关注。然而,缺少高度匹配的电极材料阻碍了它们的发展。因此,探索高性能和低成本的电极材料对于这些设备的潜在应用至关重要。铋 (Bi) 具有较高的能量密度和相对较低的氧化还原电位电压范围,在水性电池和海水淡化领域显示出巨大的潜力,并在过去几十年取得了重大进展。在这篇综述中,全面地总结和讨论了铋基电极的独特性能和合成方法及其近年来的应用。综述中首先介绍了常用的铋基电极制备方法,包括水热法, 电沉积法等。然后,对铋基复合材料水系电池中的应用进行了总结,如 Ni//Bi 电池和海水淡化。在文章的最后,对于铋基材料未来研究方向提出了挑战和展望。

a Synthetic route of yolk-shell Bi@C nanospheres. Reproduced with permission from Ref. [52]. Copyright 2020, Springer-Verlag GmbH Germany. b Schematic illustration of durian-like Bi0.75Sb0.25 pyramid arrays. Reproduced with permission from Ref. [30]. Copyright 2020, American Chemical Society. c Illustration of topotactic transformation from BiOCl to T-BiNS and crystal structure transformation process of BiOCl to Bi. Reproduced with permission from Ref. [59]. Copyright 2020, The Royal Society of Chemistry. d Schematic illustration of synthesis procedure for P-Bi-C sample on carbon cloth. Reproduced with permission from Ref. [60]. Copyright 2018, WILEY-VCH

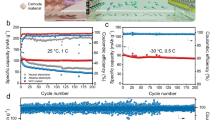

a Specific capacity of NiCo2O4//Bi battery during bending process and (inset) digital photos of NiCo2O4//Bi battery under normal and bending conditions. Reproduced with permission from Ref. [56]. Copyright 2016, WILEY-VCH. b Capacity comparison of P-Bi-C electrode with previous studies considering mass loading. Reproduced with permission from Ref. [60]. Copyright 2018, WILEY-VCH. c Cycling performance of Bi and A-Bi electrodes tested in a three-electrode system at 100 mV·s−1 using cyclic voltammetry (CV) measurements for 20,000 cycles. Reproduced with permission from Ref. [74]. Copyright 2018, The Royal Society of Chemistry. d Schematic illustration for synthesis of Bi@C nanospheres. Reproduced with permission from Ref. [76]. Copyright 2020, The Royal Society of Chemistry. e Cycling durability of TL-Bi electrode after press treatment at 40 mV·s−1 for 14,000 cycles and without pressure at 40 mV·s−1 for 2800 cycles, and (inset) CV curves of TL-Bi electrode with press treatment before and after cycling test. Reproduced with permission from Ref. [75]. Copyright 2020, Elsevier B.V

a Bi electrodes capacity in LiOH, NaOH and KOH electrolytes. Reproduced with permission from Ref. [77]. Copyright 2015, MDPI. b Rreal specific capacity of L-Bi2O3 and H-Bi2O3 electrodes at different current densities. Reproduced with permission from Ref. [80]. Copyright 2017, The Royal Society of Chemistry. c CV curves at a scan of 10 mV·s−1 of Bi2O3 and Bi2O3-x. Reproduced with permission from Ref. [81]. Copyright 2019, Elsevier B.V. d Discharge polarization curve of Al-CO2 with scrap Al as electrode. Reproduced with permission from Ref. [89]. Copyright 2020, The Royal Society of Chemistry

a Pourbaix diagrams for Bi in 0.6 mol·L−1 Cl− solution at 25 °C; b linear sweep voltammetry (LSV) curves for reduction of BiOCl in a 0.6 mol·L−1 NaCl solution (pH 6.4, red line), and a 70 mmol·L−1 HCl solution (pH 1.15, blue line) recorded at a scan rate of 5 mV·s−1, where equilibrium reduction potential of BiOCl to Bi is marked by dashed line. Reproduced with permission from Ref. [37]. Copyright 2017, American Chemical Society. c Process flow diagram of batch testing, where with electric current varying in positive and negative applied, salt goes through desorption and adsorption process; d electrochemical salt removal/release capacity and electric charge efficiency during cycling. Reproduced with permission from Ref. [100]. Copyright 2017, The Royal Society of Chemistry. e Ion remove capacity during ions capturing step in 3 and 10 mmol·L−1 mixture. Reproduced with permission from Ref. [101]. Copyright 2020, Elsevier B.V. f Ion removal capacity of Cl− and SO42− by Bi electrode in a mixed NaCl and Na2SO4 solution with different mole ratio (MR) of Cl−/SO42− at voltage of 1.2 V. Reproduced with permission from Ref. [102]. Copyright 2020, Elsevier B.V

a Scanning electron microscope (SEM) image of bismuth-carbon nanotexture composites; b discharge and charge curves and c cycling performance of AgCl/Bi battery under the current density of 1200 mA·g−1. Reproduced with permission from Ref. [51]. Copyright 2020, Springer-Verlag GmbH Germany. d Specific capacitance of BiOCl-CNF-1, BiOCl-CNF-2 and BiOCl-CNF-3 and pristine BiOCl in 1 mol·L−1 NaCl solution; e-g SEM images of BiOCl-CNF-1, BiOCl-CNF-2 and BiOCl-CNF-3; h comparison of desalination rate and desalination capacity plots of RCDI system assembled with BiOCl-CNF-2 electrodes and other systems from literatures; i desalination capacities and charge efficiencies of BiOCl-CNF-2-based RCDI system at various currents. Reproduced with permission from Ref. [103]. Copyright 2021, Elsevier B.V

Similar content being viewed by others

References

Nayak PK, Yang L, Brehm W, Adelhelm P. From lithium-ion to sodium-ion batteries: advantages, challenges, and surprises. Angew Chem Int Ed. 2018;57(1):102.

Liu WX, Yin RL, Xu XL, Zhang L, Shi WH, Cao XH. Structural engineering of low-dimensional metal-organic frameworks: synthesis, properties, and applications. Adv Sci. 2019;6(12):1802373.

Liu WX, Zheng D, Deng TQ, Chen QL, Zhu CZ, Pei CJ, Li H, Wu FF, Shi WH, Yang SW, Zhu YH, Cao XH. Boosting electrocatalytic activity of 3D-block metal (hydro)oxides by ligand-induced conversion. Angew Chem Int Ed. 2021;60(19):10614.

Cai ZL, Peng ZL, Wang MQ, Wu JY, Fan HS, Zhang YF. High-pseudocapacitance of porous and square NiO@NC nanosheets for high-performance lithium-ion batteries. Rare Met. 2021;40(6):1451.

Wang F, Liu Y, Wei HJ, Li TF, Xiong XH, Wei SZ, Ren FZ, Volinsky AA. Recent advances and perspective in metal coordination materials-based electrode materials for potassium-ion batteries. Rare Met. 2021;40(2):448.

Cheng XB, Zhang R, Zhao CZ, Zhang Q. Toward safe lithium metal anode in rechargeable batteries: a review. Chem Rev. 2017;117(15):10403.

Fu J, Cano ZP, Park MG, Yu A, Fowler M, Chen ZW. Electrically rechargeable zinc-air batteries: progress, challenges, and perspectives. Adv Mater. 2017;29(7):1604685.

Zhang R, Chen XR, Chen X, Cheng XB, Zhang XQ, Yan C, Zhang Q. Lithiophilic sites in doped graphene guide uniform lithium nucleation for dendrite-free lithium metal anodes. Angew Chem Int Ed. 2017;56(27):7764.

Feng JX, Zheng D, Gao XL, Que WB, Shi WH, Liu WX, Wu FF, Cao XH. Three-dimensional ordered porous carbon for energy conversion and storage applications. Front Energy Res. 2020;8:210.

Xu XL, Shi WH, Liu WX, Ye SF, Yin RL, Zhang L, Xu LX, Chen MH, Zhong MQ, Cao XH. Preparation of two-dimensional assembled Ni-Mn-C ternary composites for high-performance all-solid-state flexible supercapacitors. J Mater Chem A. 2018;6(47):24086.

Yang M, Zhou Z. Recent breakthroughs in supercapacitors boosted by nitrogen-rich porous carbon materials. Adv Sci. 2017;4(8):1600408.

Choi C, Ashby DS, Butts DM, DeBlock RH, Wei QL, Lau J, Dunn B. Achieving high energy density and high power density with pseudocapacitive materials. Nat Rev Mater. 2019;5(1):5.

Xu BL, Qi SH, He PB, Ma JM. Antimony- and bismuth-based chalcogenides for sodium-ion batteries. Chem-Asian J. 2019;14(17):2925.

Zeng K, Zhang DK. Recent progress in alkaline water electrolysis for hydrogen production and applications. Prog Energy Combus. 2010;36(3):307.

Liu WX, Zheng D, Zhang L, Yin RL, Xu XL, Shi WH, Wu FF, Cao XH, Lu XH. Bioinspired interfacial engineering of a CoSe2 decorated carbon framework cathode towards temperature-tolerant and flexible Zn-air batteries. Nanoscale. 2021;13(5):3019.

Yang Q, Liu WX, Wang BQ, Zhang WN, Zeng XQ, Zhang C, Qin YJ, Sun XM, Wu TP, Liu JF, Huo FW, Lu J. Regulating the spatial distribution of metal nanoparticles within metal-organic frameworks to enhance catalytic efficiency. Nat Commun. 2017;8:14429.

Wu X, Chen Y, Xing Z, Lam CWK, Pang SS, Zhang W, Ju Z. Advanced carbon-based anodes for potassium-ion batteries. Adv Energy Mater. 2019;9(21):1900343.

Yoo HD, Liang YL, Dong H, Lin JH, Wang H, Liu YS, Ma L, Wu TP, Li YF, Ru Q, Jing Y, An QY, Zhou W, Guo JH, Lu J, Pantelides ST, Qian XF, Yao Y. Fast kinetics of magnesium monochloride cations in interlayer-expanded titanium disulfide for magnesium rechargeable batteries. Nat Commun. 2017;8(1):339.

Yang H, Xu R, Yao Y, Ye SF, Zhou XF, Yu Y. Multicore-shell Bi@N-doped carbon nanospheres for high power density and long cycle life sodium- and potassium-ion anodes. Adv Funct Mater. 2019;29(13):1809195.

Fiordiponti P, Pistoia G, Temperoni C. Behavior of Bi2O3 as a cathode for lithium cells. J Electrochem Soc. 1978;125(1):14.

Wang XM, Tatsuo N, Isamu U. Lithium alloy formation at bismuth thin layer electrode and its kinetics in propylene carbonate electrolyte. J Power Sources. 2002;104(1):90.

Huang M, Xi BJ, Shi NX, Feng JK, Qian YT, Xue DF, Xiong SL. Quantum-matter Bi/TiO2 heterostructure embedded in N-doped porous carbon nanosheets for enhanced sodium storage. Small Struct. 2020;2(4):2000085.

Shen KX, Zhang ZS, Wang SF, Ru Q, Zhao LZ, Sun LF, Hou XH, Chen FM. Cucumber-shaped construction combining bismuth nanoparticles with carbon nanofiber networks as a binder-free and freestanding anode for Li-ion batteries. Energy Fuel. 2020;34(7):8987.

Wang XX, Wu Y, Huang P, Chen P, Wang ZY, Xu XW, Xie J, Yan J, Li SG, Tu J, Ding YL. A multi-layered composite assembly of Bi nanospheres anchored on nitrogen-doped carbon nanosheets for ultrastable sodium storage. Nanoscale. 2020;12(46):23682.

Yang H, Chen LW, He FX, Zhang JQ, Feng YZ, Zhao LK, Wang B, He LX, Zhang QB, Yu Y. Optimizing the void size of yolk-shell Bi@void@C nanospheres for high-power-density sodium-ion batteries. Nano Lett. 2020;20(1):758.

Hu CJ, Zhu YS, Ma GY, Tian F, Zhou YL, Yang J, Qian YT. Sandwich-structured dual carbon modified bismuth nanosphere composites as long-cycle and high-rate anode materials for sodium-ion batteries. Electrochim Acta. 2021;365:137379.

Zuo WH, Zhu WH, Zhao DF, Sun YF, Li YY, Liu JP, Lou XW. Bismuth oxide: a versatile high-capacity electrode material for rechargeable aqueous metal-ion batteries. Energy Environ Sci. 2016;9(9):2881.

Huang YZ, Hu X, Li JW, Zhang JS, Cai DP, Sa BS, Zhan HB, Wen ZH. Rational construction of heterostructured core-shell Bi2S3@Co9S8 complex hollow particles toward high-performance Li- and Na-ion storage. Energy Storage Mater. 2020;29:121.

Liu WX, Huang JJ, Yang Q, Wang SJ, Sun XM, Zhang WN, Liu JF, Huo FW. Multi-shelled hollow metal-organic frameworks. Angew Chem Int Ed. 2017;56(20):5512.

Ni JF, Li XY, Sun ML, Yuan YF, Liu TC, Li L, Lu J. Durian-inspired design of bismuth-antimony alloy arrays for robust sodium storage. ACS Nano. 2020;14(7):9117.

Shi WH, Mao J, Xu XL, Liu WX, Zhang L, Cao XH, Lu XH. An ultra-dense NiS2/reduced graphene oxide composite cathode for high-volumetric/gravimetric energy density nickel-zinc batteries. J Mater Chem A. 2019;7(26):15654.

Liu JL, Xu CH, Chen Z, Ni SB, Shen ZX. Progress in aqueous rechargeable batteries. Green Energy Environ. 2018;3(1):20.

Wu FF, Gao XB, Xu XL, Jiang YN, Gao XL, Yin RL, Shi WH, Liu WX, Lu G, Cao XH. MnO2 nanosheet-assembled hollow polyhedron grown on carbon cloth for flexible aqueous zinc-ion batteries. Chemsuschem. 2020;13(6):1537.

Shi XD, Xu ZM, Han C, Shi RZ, Wu XW, Lu B, Zhou J, Liang SQ. Highly dispersed cobalt nanoparticles embedded in nitrogen-doped graphitized carbon for fast and durable potassium storage. Nano-Micro Lett. 2021;13(1):21.

Wang HW, Xu DM, Qiu RY, Tang SS, Li S, Wang R, He BB, Gong YS, Fan HJ. Aligned arrays of Na2Ti3O7 nanobelts and nanowires on carbon nanofiber as high-rate and long-cycling anodes for sodium-ion hybrid capacitors. Small Struct. 2020;2(2):2000073.

Gong DC, Wei CY, Liang ZW, Tang YB. Recent advances on sodium-ion batteries and sodium dual-ion batteries: state-of-the-art Na+ host anode materials. Small Sci. 2021. https://doi.org/10.1002/smsc.202100014.

Nam DH, Choi KS. Bismuth as a new chloride-storage electrode enabling the construction of a practical high capacity desalination battery. J Am Chem Soc. 2017;139(32):11055.

Devi N, Ray SS. Performance of bismuth-based materials for supercapacitor applications: A review. Mater Today Commun. 2020;25:101691.

Liu XH, Zhang SL, Guo SY, Cai B, Yang SYA, Shan FK, Pumera M, Zeng HB. Advances of 2D bismuth in energy sciences. Chem Soc Rev. 2020;49(1):263.

Wang AN, Hong WW, Yang L, Tian Y, Qiu XJ, Zou GQ, Hou HS, Ji XB. Bi-based electrode materials for alkali metal-ion batteries. Small. 2020;16(48):2004022.

Xu K, Wang L, Xu X, Dou SX, Hao WC, Du Y. Two dimensional bismuth-based layered materials for energy-related applications. Energy Storage Mater. 2019;19:446.

Yang FH, Yu F, Zhang ZA, Zhang K, Lai YQ, Li J. Bismuth nanoparticles embedded in carbon spheres as anode materials for sodium/lithium-ion batteries. Chem. 2016;22(7):2333.

Yin H, Li QW, Cao ML, Zhang W, Zhao H, Li C, Huo KF, Zhu MQ. Nanosized-bismuth-embedded 1D carbon nanofibers as high-performance anodes for lithium-ion and sodium-ion batteries. Nano Res. 2017;10(6):2156.

Li XY, Qu JK, Yin HY. Electrolytic alloy-type anodes for metal-ion batteries. Rare Met. 2020;40(2):329.

Sun JG, Li MC, Oh JAS, Zeng KY, Lu L. Recent advances of bismuth based anode materials for sodium-ion batteries. Mater Technol. 2018;33(8):563.

Wang CC, Wang LB, Li FJ, Cheng FY, Chen J. Bulk bismuth as a high-capacity and ultralong cycle-life anode for sodium-ion batteries by coupling with glyme-based electrolytes. Adv Mater. 2017;29(35):1702212.

Kravchyk KV, Piveteau L, Caputo R, He M, Stadie NP, Bodnarchuk MI, Lechner RT, Kovalenko MV. Colloidal bismuth nanocrystals as a model anode material for rechargeable Mg-ion batteries: atomistic and mesoscale insights. ACS Nano. 2018;12(8):8297.

Huang JQ, Lin XY, Tan H, Zhang B. Bismuth microparticles as advanced anodes for potassium-ion battery. Adv Energy Mater. 2018;8(19):1703496.

Wu MG, Xu BL, Zhang YF, Qi SH, Ni W, Hu J, Ma JM. Perspectives in emerging bismuth electrochemistry. Chem Eng J. 2020;381(1):122558.

Li XQ, Xiao D. Modification of corroded metal (Ni or Fe) foam for high-performance rechargeable alkaline Ni/Fe batteries. ChemElectroChem. 2020;7(14):3098.

Zhang ZS, Shen KX, Zhou Y, Hou XH, Ru Q, He QY, Su CY, Sun LF, Aung SH, Chen FM. The composite electrode of Bi@carbon-texture derived from metal-organic frameworks for aqueous chloride ion battery. Ionics. 2019;26(5):2395.

Xu XJ, Zhang DC, Wang ZS, Zuo SY, Shen JD, Liu ZB, Liu J. Facile synthesis of yolk-shell Bi@C nanospheres with superior Li-ion storage performances. Acta Metall Sin. 2020;34(3):347.

Liu YL, Li MQ, Wang GG, Dang LY, Li F, Pam ME, Zhang HY, Han JC, Yang HY. Bismuth oxide selenium/graphene oxide composites: toward high-performance electrodes for aqueous alkaline battery. Energy Environ Mater. 2020. https://doi.org/10.1002/eem2.12130.

Xu JL, Wei W, Zhang X, Liang L, Xu MT. Lotus-stalk Bi4Ge3O12 as binder-free anode for lithium and sodium ion batteries. Chinese Chem Lett. 2019;30(6):1341.

Zhu YT, Liu J, Liao YH, Lv W, Ma LL, Wang CG. Degradation of vanillin during lignin valorization under alkaline oxidation. Top Curr Chem. 2018;376(4):29.

Zeng YX, Lin ZQ, Meng Y, Wang YC, Yu MH, Lu XH, Tong YX. Flexible ultrafast aqueous rechargeable Ni//Bi battery based on highly durable single-crystalline bismuth nanostructured anode. Adv Mater. 2016;28(41):9188.

Wang MY, Xie SL, Tang CQ, Zhao Y, Liao M, Ye L, Wang BJ, Peng HS. Making fiber-shaped Ni//Bi battery simultaneously with high energy density, power density, and safety. Adv Funct Mater. 2019;30(3):1905971.

Meng CX, Das P, Shi XY, Fu Q, Müllen K, Wu ZS. In situ and operando characterizations of 2D materials in electrochemical energy storage devices. Small Sci. 2021;1(4):2000076.

Zhu QC, Cheng MY, Yang XF, Zhang B, Wan ZZ, Xiao Q, Yu Y. Self-supported ultrathin bismuth nanosheets acquired by in situ topotactic transformation of BiOCl as a high performance aqueous anode material. J Mater Chem A. 2019;7(12):6784.

Zeng YX, Lin ZQ, Wang ZF, Wu MM, Tong YX, Lu XH. In situ activation of 3D porous Bi/carbon architectures: toward high-energy and stable nickel-bismuth batteries. Adv Mater. 2018;30(18):1707290.

Sun JF, Li ZP, Wang JQ, Hong W, Gong PW, Wen P, Wang ZF, Yang SR. Ni/Bi battery based on Ni(OH)2 nanoparticles/graphene sheets and Bi2O3 rods/graphene sheets with high performance. J Alloy Compd. 2015;643:231.

Demir E, Hayat Soytas S, Demir C. Bismuth oxide nanoparticles embedded carbon nanofibers as self-standing anode material for Na-ion batteries. Solid State Ionics. 2019;342:115066.

Li W, Dahn JR, Wainwright DS. Rechargeable lithium batteries with aqueous electrolytes. Science. 1994;264(5162):1115.

Hu R, Fang Yz, Liu X, Zhu K, Cao D, Yi J, Wang G. Synthesis of SnS2 ultrathin nanosheets as anode materials for potassium ion batteries. Chem Res Chinese U. 2021; 37(2):311.

Dong S, Song YL, Fang YZ, Zhu K, Ye K, Gao YY, Yan J, Wang GL, Cao DX. Microwave-assisted synthesis of carbon dots modified graphene for full carbon-based potassium ion capacitors. Carbon. 2021;178:1.

Ma NY, Wu PJ, Wu YX, Jiang DH, Lei GT. Progress and perspective of aqueous zinc-ion battery. Funct Mater Lett. 2019;12(5):1930003.

Shan LT, Wang YR, Liang SQ, Tang BY, Yang YQ, Wang ZQ, Lu B, Zhou J. Interfacial adsorption-insertion mechanism induced by phase boundary toward better aqueous Zn-ion battery. InfoMat. 2021. https://doi.org/10.1002/inf2.12223.

Huang JT, Zhou J, Liang SQ. Guest pre-intercalation strategy to boost the electrochemical performance of aqueous Zinc-ion battery cathodes. Acta Phys-Chim Sin. 2021;37(3):2005020.

Xiao ZH, Wang Y, Huang YC, Wei ZX, Dong CL, Ma JM, Shen SH, Li YF, Wang SY. Filling the oxygen vacancies in Co3O4 with phosphorus: an ultra-efficient electrocatalyst for overall water splitting. Energy Environ Sci. 2017;10(12):2563.

Li SS, Hao XG, Abudula A, Guan GQ. Nanostructured Co-based bifunctional electrocatalysts for energy conversion and storage: current status and perspectives. J Mater Chem A. 2019;7(32):18674.

Sun JF, Wang JQ, Li ZP, Niu LY, Hong W, Yang SR. Assembly and electrochemical properties of novel alkaline rechargeable Ni/Bi battery using Ni(OH)2 and (BiO) −4 CO3(OH)2 microspheres as electrode materials. J Power Sources. 2015;274:1070.

Li X, Guan C, Hu YT, Wang J. Nanoflakes of Ni-Co LDH and Bi2O3 assembled in 3D carbon fiber network for high-performance aqueous rechargeable Ni/Bi battery. ACS Appl Mater Interfaces. 2017;9(31):26008.

Zan GT, Wu T, Hu P, Zhou YH, Zhao SL, Xu SM, Chen J, Cui Y, Wu QS. An approaching-theoretical-capacity anode material for aqueous battery: hollow hexagonal prism Bi2O3 assembled by nanoparticles. Energy Storage Mater. 2020;28:82.

Zhang P, Zeng YX, Wang MY, Xu W, Liu Y, Lu XH. A highly crystalline bismuth superstructure for ultrastable and high-performance flexible aqueous nickel-bismuth batteries. J Mater Chem A. 2018;6(19):8895.

Liang XY, Xiang B, Zou XF, Chen F, Hao JY, Hu Q, Li WP. Construction of three-dimensional ordered structure of crystalline bismuth for long life aqueous nickel-bismuth batteries. Appl Surf Sci. 2020;515:145977.

Yao JJ, Li LP, Li N, Jiang J, Wang YL, Zhu JH. Fast-response/stable Ni-Bi cells achieved using hollowed-out Bi@carbon nanospheres: a preferred electricity storage choice to couple with clean energy harvesting. Mater Chem Front. 2020;4(4):1249.

Zuo WH, Xu P, Li YY, Liu JP. Direct growth of bismuth film as anode for aqueous rechargeable batteries in LiOH, NaOH and KOH electrolytes. Nanomaterials. 2015;5(4):1756.

Pan JQ, Wang Q, Sun YZ, Wang ZH. Analysis of electrochemical mechanism of coprecipitated nano-Ag4Bi2O5 as super high charge-discharge rate cathode materials for aqueous rechargeable battery. Electrochim Acta. 2012;59:515.

Ni JF, Bi XX, Jiang Y, Li L, Lu J. Bismuth chalcogenide compounds Bi2X3 (X=O, S, Se): applications in electrochemical energy storage. Nano Energy. 2017;34:356.

Zheng HB, Li HD, Yu MH, Zhang M, Tong YX, Cheng FL, Lu XH. Vertical bismuth oxide nanosheets with enhanced crystallinity: promising stable anodes for rechargeable alkaline batteries. J Mater Chem A. 2017;5(48):25539.

Zheng HB, Zeng YX, Zhang HZ, Zhao XY, Chen MH, Liu J, Lu XH. Oxygen vacancy activated Bi2O3 nanoflowers as a high-performance anode for rechargeable alkaline battery. J Power Sources. 2019;433:126684.

Alireza A, E WR, Leily M, Mohammad A, Amir C, R JJ, Sina R, Zahra H, Baharak S, S AR, Badri N, Pedram A, C RP, Anh N, Marton V, Jeffrey G, Robert K, A CL, Amin SK. A long-cycle-life lithium-CO2 battery with carbon neutrality. Adv Mater. 2019; 31 (40):e1902518.

Zhang WC, Hu CG, Guo ZP, Dai LM. High-performance K-CO2 batteries based on metal-free carbon electrocatalysts. Angew Chem Int Ed. 2020;59(9):3470.

Hu XF, Sun JC, Li ZF, Zhao Q, Chen CC, Chen J. Rechargeable room-temperature Na-CO2 batteries. Angew Chem Int Ed. 2016;55(22):6482.

Ling YF, Ma QL, Yu YF, Zhang B. Optimization strategies for selective CO2 electroreduction to fuels. T Tianjin U. 2021;27(3):180.

Liu JP, Peng WC, Li Y, Zhang FB, Fan XB. 2D MXene-based materials for electrocatalysis. T Tianjin U. 2020;26(3):149.

Chen Y, Guo RJ, Peng XY, Wang XQ, Liu XJ, Ren JQ, He J, Zhuo LC, Sun JQ, Liu YF, Wu YE, Luo J. Highly productive electrosynthesis of ammonia by admolecule-targeting single Ag sites. ACS Nano. 2020;14(6):6938.

Lü F, Bao HH, Mi YY, Liu YF, Sun JQ, Peng XY, Qiu Y, Zhuo LC, Liu XJ, Luo J. Electrochemical CO2 reduction: from nanoclusters to single atom catalysts. Sustain Energy Fuels. 2020;4(3):1012.

Ding P, Zhang J, Han N, Zhou Y, Jia L, Li YG. Simultaneous power generation and CO2 valorization by aqueous Al-CO2 batteries using nanostructured Bi2S3 as the cathode electrocatalyst. J Mater Chem A. 2020;8(25):12385.

Xu CJ, Li BH, Du HD, Kang FY. Energetic zinc ion chemistry: the rechargeable zinc ion battery. Angew Chem Int Ed. 2012;51(4):933.

Xu WW, Wang Y. Recent progress on zinc-ion rechargeable batteries. Nano-Micro Lett. 2019;11(1):90.

Xiong T, Wang YM, Yin BS, Shi W, Lee WSV, Xue JM. Bi2S3 for aqueous Zn ion battery with enhanced cycle stability. Nano-Micro Lett. 2019;12(1):8.

Shi WH, Liu XY, Deng TQ, Huang SZ, Ding M, Miao XH, Zhu CZ, Zhu YH, Liu WX, Wu FF, Gao CJ, Yang SW, Yang HY, Shen JN, Cao XH. Enabling superior sodium capture for efficient water desalination by a tubular polyaniline decorated with prussian blue nanocrystals. Adv Mater. 2020;32(33):1907404.

Ali A, Tufa RA, Macedonio F, Curcio E, Drioli E. Membrane technology in renewable-energy-driven desalination. Renew Sust Energy Rev. 2018;81:1.

Jones E, Qadir M, van Vliet MTH, Smakhtin V, Kang SM. The state of desalination and brine production: a global outlook. Sci Total Environ. 2019;657:1343.

Ding GC, Zhu LM, Yang Q, Xie LL, Cao XY, Wang YL, Liu JP, Yang XL. NaV3O8/poly (3,4-ethylenedioxythiophene) composites as high-rate and long-lifespan cathode materials for reversible sodium storage. Rare Met. 2020;39(8):865.

Wang D, Cai P, Zou GQ, Hou HS, Ji XB, Tian Y, Long Z. Ultra-stable carbon-coated sodium vanadium phosphate as cathode material for sodium-ion battery. Rare Met. 2021. https://doi.org/10.1007/s12598-021-01743-y.

Nam DH, Lumley MA, Choi KS. A desalination battery combining Cu3[Fe(CN)6]2 as a Na-storage electrode and Bi as a Cl-storage electrode enabling membrane-free desalination. Chem Mater. 2019;31(4):1460.

Nam D, Choi K. Electrochemical desalination using Bi/BiOCl electrodialysis cells. ACS Sustain Chem Eng. 2018;6(11):15455.

Chen F, Huang Y, Guo L, Sun L, Wang Y, Yang HY. Dual-ions electrochemical deionization: a desalination generator. Energy Environ Sci. 2017;10(10):2081.

Min XB, Zhu MF, He YJ, Wang YY, Deng HY, Wang S, Jin LF, Wang HY, Zhang LY, Chai LY. Selective removal of Cl- and F- from complex solution via electrochemistry deionization with bismuth/reduced graphene oxide composite electrode. Chemosphere. 2020;251:126319.

Chang JJ, Li YP, Duan F, Su CL, Li YJ, Cao HB. Selective removal of chloride ions by bismuth electrode in capacitive deionization. Sep Purif Technol. 2020;240:116600.

Liu Y, Gao X, Wang ZP, Wang K, Dou XY, Zhu HG, Yuan X, Pan LK. Controlled synthesis of bismuth oxychloride-carbon nanofiber hybrid materials as highly efficient electrodes for rocking-chair capacitive deionization. Chem Eng J. 2021;403:126326.

Qin TT, Chu XF, Deng T, Wang BR, Zhang XY, Dong TW, Li ZM, Fan XF, Ge X, Wang ZZ, Wang P, Zhang W, Zheng WT. Reinventing the mechanism of high-performance Bi anode in aqueous K+ rechargeable batteries. J Energy Chem. 2020;48:21.

Cheng SM, Cheng WL, Gu XJ, Yu H, Wang ZF, Wang HX, Wang LF. Discharge properties of low-alloyed Mg-Bi-Ca alloys as anode materials for Mg-air batteries: influence of Ca alloying. J Alloy Compd. 2020;823:153779.

Kang W, Kong X, Li J, Wang P, Sun Y, Zhang X, Yang H, Lin B. Novel aqueous rechargeable nickel-bismuth batteries based on porous Bi2MoO6 microspheres and CoxNi1-xMoO4@NiCo-layered double hydroxide heterostructure nanoarrays. Mater Today Energy. 2020;18:100549.

Chen WB, Zhang LN, Ji ZJ, Zheng YD, Yuan S, Wang Q. Self-supported Bi2MoO6 nanosheet arrays as advanced integrated electrodes for Li-ion batteries with super high capacity and long cycle life. Nano. 2018;13(6):1850066.

Liang BD, Yuan LY, Fei SY, Ping GZ, Ping LJ. Directly grown nanostructured electrodes for high-power and high-stability alkaline nickel/bismuth batteries. Sci China Mater. 2018;62(4):487.

Bruck AM, Kim MA, Ma L, Ehrlich SN, Okasinski JS, Gallaway JW. Bismuth enables the formation of disordered birnessite in rechargeable alkaline batteries. J Electrochem Soc. 2020;167(11):110514.

Kim M, Ju H, Kim J. Highly efficient bifunctional catalytic activity of bismuth rhodium oxide pyrochlore through tuning the covalent character for rechargeable aqueous Na-air batteries. J Mater Chem A. 2018;18:8523.

Shin J, You JM, Lee JZ, Kumar R, Yin L, Wang J, Meng YS. Deposition of ZnO on bismuth species towards a rechargeable Zn-based aqueous battery. Phys Chem Chem Phys. 2016;18(38):26376.

Acknowledgements

This study was financially supported by the Leading Innovative and Entrepreneur Team Introduction Program of Zhejiang (No. 2020R01002), the National Natural Science Foundation of China (Nos. 51972286, 21905246 and 22005268), the Natural Science Foundation of Zhejiang Province (Nos. LR19E020003, LZ21E020003, LQ21E020004 and LQ20B010011) and the Fundamental Research Funds for the Provincial Universities of Zhejiang (No. RF-B-2020004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dai, XJ., Niu, XX., Fu, WQ. et al. Bismuth-based materials for rechargeable aqueous batteries and water desalination. Rare Met. 41, 287–303 (2022). https://doi.org/10.1007/s12598-021-01853-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01853-7