Abstract

Ultrafine rare-earth oxides (REOs) are widely applied in all fields of daily life, but the conventional preparation methods are limited by a long procedure, low efficiency and severe environmental pollution. Our team has independently developed a jet pyrolysis reactor for the preparation of ultrafine cerium oxides, and this process has theoretical significance and practical application values. In this study, gas–solid pyrolysis reactions inside the jet-flow pyrolysis reactor were numerically simulated. We performed a coupling computation of the combustion, phase transformation and gas–solid reaction on Fluent and user-defined functions. We characterized the flows of different phases as well as the compositions and distributive laws of the reactants/products in the reactor. The gas-phase inlet velocity and dynamic pressure/additional pressure were related by a quadratic function. The velocity at the throat inlet changed the most, and the outlet velocity was very stable. The CeO2 concentrations were obviously stratified. This study enriches theories of jet-flow pyrolysis and theoretically underlies the optimization and popularization of self-developed pyrolysis reactors.

Similar content being viewed by others

References

Chen WZ, Yin HR, Ma ZH, Guo HW. Research progress of SmCo5 nanoparticles and nanocomposites. Chin J Rare Met. 2018;42(1):88.

Liu JL, Zhang P, Zhang XK, Xie QQ, Pan DJ, Zhang J, Zhang M. Synthesis and microwave absorbing properties of La-doped Sr-hexaferrite nanopowders via sol–gel auto-combustion method. Rare Met. 2017;36(9):1.

Yang Q, Hu H, Wang SS. Preparation and desulfurization activity of nano-CeO2/γ-Al2O3, catalysts. Rare Met. 2018;37(7):554.

Peyghambari SM, Yousefpour M. Electrodeposition of nanostructured Ti/(Ru + Ti + Ce)O2 coatings. Rare Met. 2018;37(1):13.

Xiang L. Study on the Preparation of Light Rare Earth Oxide from Rare Earth Chloride Roasted Statically. Shenyang: Northeastern University; 2010. 15.

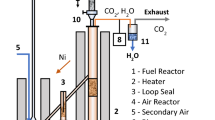

Lv C, Zhao QY, Zhang ZM, Dou ZH, Zhang TA, Zhao HL. Numerical simulation of fluid dynamics in rare earth chloride solution in jet-flow pyrolysis reactor. Trans Nonferrous Met Soc China. 2015;25(3):997.

Lv C, Zhang ZM, Zhao QY, Dou ZH, Zhang TA, Zhao HL. Numerical simulation: preparation of La2O3 in a jet pyrolysis reactor. Rare Met. 2015;34(8):600.

Alhaddad M, Rendek E, Corriou JP, Mauviel G. Biomass fast pyrolysis: experimental analysis and modeling approach. Energy Fuels. 2010;24(9):4689.

Blasi CD, Branca C, Masotta F, Biase ED. Experimental analysis of reaction heat effects during beech wood pyrolysis. Energy Fuels. 2013;27(5):2665.

Dupont C, Commandre JM, Gauthier P, Boissonnet G, Salvador S, Schweich D. Biomass pyrolysis experiments in an analytical entrained flow reactor between 1073 K and 1273 K. Fuel. 2008;87(7):1155.

Suriapparao DV, Vinu R. Effects of biomass particle size on slow pyrolysis kinetics and fast pyrolysis product distribution. Rare Met. 2018;39(3):465.

Babu B, Chaurasia A. Modeling for pyrolysis of solid particle: kinetics and heat transfer effects. Energy Convers Manag. 2003;44(14):2251.

Bharadwaj A, Baxter LL, Robinson AL. Effects of intraparticle heat and mass transfer on biomass devolatilization: experimental results and model predictions. Energy Fuels. 2004;18(4):1021.

Blondeau J, Jeanmart H. Biomass pyrolysis at high temperatures: prediction of gaseous species yields from an anisotropic particle. Biomass Bioenerg. 2012;41(41):107.

Grønli MG, Melaaen MC. Mathematical model for wood pyrolysis comparison of experimental measurements with model predictions. Energy Fuels. 2000;14(4):791.

Kung HC. A mathematical model of wood pyrolysis. Combust Flame. 1972;18(2):18.

Krutof A, Hawboldt KA. Upgrading of biomass sourced pyrolysis oil review: focus on co-pyrolysis and vapour upgrading during pyrolysis. Biomass Conv Bioref. 2018;8(3):775.

Park WC, Atreya A, Baum HR. Experimental and theoretical investigation of heat and mass transfer processes during wood pyrolysis. Combust Flame. 2010;157(3):481.

Larfeldt J, Leckner B, Melaaen MC. Modelling and measurements of the pyrolysis of large wood particles. Fuel. 2000;79(13):1637.

Sadhukhan AK, Gupta P, Saha RK. Modelling and experimental studies on pyrolysis of biomass particles. J Anal Appl Pyrol. 2008;81(2):183.

Li XG, Ma BG, Wu B, Jian SW, Luo ZT. Numerical simulation and optimization of cold airflow field in sprayed calciners. J Harbin Inst Technol. 2009;41(4):226.

Zhao HL, Liu Y, Zhang TA, Gu SQ. Computational fluid dynamics (CFD) simulations on multiphase flow in mechanically agitated seed precipitation tank. JOM. 2014;66(7):1218.

Zhao HL, Zhang ZM, Zhang TA, Liu Y, Gu SQ, Zhang C. Experimental and CFD studies of solid–liquid slurry tank stirred with an improved Intermig impeller. Trans Nonferrous Met Soc China. 2014;24(8):2650.

Pan YY, Kong SC. Simulation of biomass particle evolution under pyrolysis conditions using lattice Boltzmann method. Combust Flame. 2017;178(1):21.

He X, Chen S, Doolen GD. A novel thermal model for the lattice Boltzmann method in incompressible limit. J Comput Phys. 1998;146(1):282.

Haseli Y, Oijen JV, Goey LD. A detailed one-dimensional model of combustion of a woody biomass particle. Bioresour Technol. 2011;102(20):9772.

Motasemi F, Gerber AG. Multicomponent conjugate heat and mass transfer in biomass materials during microwave pyrolysis for biofuel production. Fuel. 2018;211(1):649.

Chen H, Ma J, Liu HT. Least square spectral collocation method for nonlinear heat transfer in moving porous plate with convective and radiative boundary conditions. Int J Therm Sci. 2018;132(10):335.

Ma J, Sun YS, Li BW. Spectral collocation method for transient thermal analysis of coupled conductive, convective and radiative heat transfer in the moving plate with temperature dependent properties and heat generation. Int J Heat Mass Transf. 2017;114(3):469.

Ma J, Sun YS, Li BW. Simulation of combined conductive, convective and radiative heat transfer in moving irregular porous fins by spectral element method. Int J Therm Sci. 2017;118(8):475.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51904069), the Natural Science Foundation of Hebei Province of China (No. E2019501085), the Colleges and Universities in Hebei Province Science and Technology Research Youth Fund (No. QN2019312), the Fundamental Research Funds for the Central Universities (No. N172303012) and the National Science and Technology Support Program (No. 2012BAE01B02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, C., Zhang, TA., Dou, ZH. et al. Numerical simulation of preparation of ultrafine cerium oxides using jet-flow pyrolysis. Rare Met. 38, 1160–1168 (2019). https://doi.org/10.1007/s12598-019-01337-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01337-9