Abstract

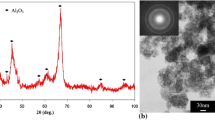

In this work, microarc oxidation (MAO) technology was used to form oxide ceramic coating on the surface of aluminum alloy. The combined additives nano-TiO2 and nano-ZnO were added into the silicate electrolyte, and the effect of the compound nano-additive on microstructure and properties of MAO coating was investigated. The results show that compared with those of the nano-additive-free coating formed on aluminum alloy, the thickness, hardness, abrasion resistance and corrosion resistance of the nano-additive-containing coating are obviously improved. The surface of coating with nano-additive becomes smooth, dense, and there are less porosities and microcracks. Moreover, the content of crystal phase α-Al2O3 and γ-Al2O3 increases visibly on the nano-additive-containing MAO coatings, and new phases Al3Ti and Zn0.6Ti0.4 are detected in the coatings, which are mainly contributed to the excellent corrosion resistance and abrasion resistance of the film. When the contents of nano-TiO2 and nano-ZnO are, respectively, 4 and 2 g·L−1, the film has better comprehensive performance, the thickness and hardness of the film could reach 52 μm and HV 692, respectively.

Similar content being viewed by others

References

Zhu ZF. Anodic Oxidation and Surface Treatment Technology of Aluminum Alloy. Beijing: Chemical Industry Press; 2011. 10.

Regone NN, Freire CMA, Ballester M. Al-based anodic oxide films structure observation using field emission gun scanning electron microscopy. J Mater Process Technol. 2006;172(1):146.

Wang KL, Zhang QB, Sun ML, Wei XG, Zhu YM. Microstructure and corrosion resistance of laser clad coatings with rare earth elements. Corros Sci. 2001;43(2):255.

Sharma SP, Dwivedi DK, Jain PK. Effect of La2O3 addition on the microstructure, hardness and abrasive wear behavior of flame sprayed Ni based coatings. Wear. 2009;267(5–8):853.

Qu L, Li M, Liu M, Zhang E, Ma C. Microstructure and corrosion resistance of ultrasonic micro-arc oxidation biocoatings on magnesium alloy. J Adv Ceram. 2013;2(3):227.

Zheng HY, Wang YK, Li BS, Han GR. Effect of Na2WO4 on properties of micro-arc oxidation ceramic coatings on aluminum alloy. J Zhejiang Univ. 2005;59(2–3):139.

Jiang BL, Zhao RB, Liang G, Li JM, Yuan F. Effect of Na2WO4 on properties of micro-arc oxidation (MAO) ceramic coatings and wear resistance of aluminum alloy. Mater Rev. 2006;20(9):155.

Yan SF, Liu XD, Chen WD, Wang ZG, Fan XJ, Xu ZG. Characteristics of coating on surface of ZrH1.8 prepared by MAO in different electrolyte systems. Chin J Rare Met. 2014;38(4):646.

Yu X, Cao C, Yao Z, Zhou D, Yin Z. Corrosion behavior of rare earth metal (REM) conversion coatings on aluminum alloy LY12. Mater Sci Eng, A. 2000;284(1–2):56.

Kurze P, Krysmann W, Schneider HG. Application fields of ANOF layers and composites. Cryst Res Technol. 1986;21(12):1603.

Liu Y, Xu J, Gao Y, Yuan Y, Gao C. Influences of additive on the formation and corrosion resistance of micro-arc oxidation ceramic coatings on aluminum alloy. Phys Proce. 2012;32(33):107.

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ. Plasma electrolysis for surface engineering. Surf Coat Technol. 1999;122(2–3):73.

Boguta DL, Rudnev VS, Yarovaya TP, Kaidalova TA, Gordienko PS. On composition of anodic-spark coatings formed on aluminum alloys in electrolytes with polyphosphate complexes of metals. Russ J Appl Chem. 2002;75(10):1605.

Yerokhin AL, Leyland A, Matthews A. Kinetic aspects of aluminium titanate layer formation on titanium alloys by plasma electrolytic oxidation. Appl Surf Sci. 2002;200(1–4):172.

Curran JA, Clyne TW. Porosity in plasma electrolytic oxide coatings. Acta Mater. 2006;54(7):1985.

Blawert C, Heitmann V, Dietzel W, Nykyforchyn HM, Klapkiv MD. Influence of electrolyte on corrosion properties of plasma electrolytic conversion coated magnesium alloys. Surf Coat Technol. 2007;201(21):8709.

Laleh M, Rouhaghdam AS, Shahrabi T, Shanghi A. Effect of alumina sol addition to micro-arc oxidation electrolyte on the properties of MAO coatings formed on magnesium alloy AZ91D. J Alloy Compd. 2010;496(496):548.

Bayati MR, Golestani-Fard F, Moshfegh AZ. The effect of growth parameters on photo-catalytic performance of the MAO-synthesized TiO2, nano-porous layers. Mater Chem Phys. 2010;120(2–3):582.

Shen D, Cai J, Li G, He D, Wu L. Effect of ultrasonic on microstructure and growth characteristics of micro-arc oxidation ceramic coatings on 6061 aluminum alloy. Vacuum. 2014;99(1):143.

Huan C, Guang C. Investigation of morphology and composition of plasma electrolytic oxidation coatings in systems of Na2SiO3-NaOH and (NaPO3)6-NaOH. J Mater Process Technol. 2007;182(1–3):28.

Wang Y, Jiang B, Lei T, Guo L. Dependence of growth features of microarc oxidation coatings of titanium alloy on control modes of alternate pulse. Mater Lett. 2004;58(12–13):1907.

Yang X, He Y, Wang D, Gao W. Cathodic micro-arc electrodeposition of thick ceramic coatings. Electrochem Solid-State Lett. 2002;5(3):C33.

Guo D, Xue L, Zu F. Phase composition, morphology and element contents of micro-arc oxidation ceramic coatings on Ti–6Al–4V alloy under different calcination conditions. Rare Met. 2016;35(11):837.

Xue WB, Wang C, Li YL, Deng ZW, Chen RY, Zhang TH. Effect of micro-arc discharge surface treatment on the tensile properties of Al–Cu–Mg alloy. Mater Lett. 2002;56(5):737.

Yang Y, Liu Y. Effects of current density on the microstructure and the corrosion resistance of alumina coatings embedded with SiC nano-particles produced by micro-arc oxidation. J Mater Sci Technol. 2010;26(11):1016.

Xiang N, Song RG, Zhao J, Hai L, Wang C. Microstructure and mechanical properties of ceramic coatings formed on 6063 aluminium alloy by micro-arc oxidation. Trans Nonferrous Meta Soc China. 2015;25(10):3323.

Huang D, Zhang XY, Wu DF, Zhou XS. Effect of rare erath(RE) additives on performances of micro-arc oxidation coatings formed on aluminum alloy. In: Proceedings of International Forum on Materials Analysis and Testing Technology (Advanced Materials Research). Qingdao. 2013:140.

Javidi M, Fadaee H. Plasma electrolytic oxidation of 2024-T3 aluminum alloy and investigation on microstructure and wear behavior. Appl Surf Sci. 2013;286(6):212.

Stojadinovic S, Vasilic R, Belca I, Petkovic M, Kasalica B. Characterization of the plasma electrolytic oxidation of aluminium in sodium tungstate. Corros Sci. 2010;52(10):3258.

Dittrich KH, Krysmann W, Kurze P, Schneider HG. Structure and properties of ANOF Layers. Cryst Res Technol. 1984;19(1):93.

Guo QQ, Jiang BL, Li JP, Li JM, Xia F, Guo YC, Li GH, Yang Z, Wang YH. Corrosion resistance of the ceramic coating on a cast Al-14Si-5Cu-3Ni-1Mg alloy formed by micro-arc oxidation. Spec Cast Nonferrous Alloys. 2008;7:557.

Cai J, Cao F, Chang L, Zheng J, Zhang J. The preparation and corrosion behaviors of MAO coating on AZ91D with rare earth conversion precursor film. Appl Surf Sci. 2011;257(8):3804.

Yan Y, Han Y, Li D, Huang J, Lian Q. Effect of NaAlO2 concentrations on microstructure and corrosion resistance of Al2O3/ZrO2 coatings formed on zirconium by micro-arc oxidation. Appl Surf Sci. 2010;256(21):6359.

Yang W, Jiang BL, Xian LY, Shi HY. Action mechanism of solutions on forming process of microarc oxidation coatings on aluminium alloy. Chin J Nonferrous Meta. 2009;19(3):464.

Xue WB, Deng ZW, Lai YC, Chen RY. Analysis of phase distribution for ceramic coatings formed by microarc oxidation on aluminum alloy. J Am Ceram Soc. 1998;81(5):1365.

Zhao JH, Zhang ZW, Wang ZH. Structure and corrosion resistance of composite ceramic coating prepared by EASP/MAO on AZ91D magnesium alloy. Chin J Rare Meta. 2013;37(4):549.

Hao GD, Hao XL, Zhu ZF. Phase composition, morphology and element contents of micro-arc oxidation ceramic coatings on Ti–6Al–4V alloy under different calcination conditions. Rare Met. 2016;35(11):836.

Xue WB, Deng ZW, Lai YC. Review of microarc oxidation technique on surface of non-ferrous metals. Heat Treat Met. 2000;1:1.

Erarslan Y. Wear performance of in situ aluminum matrix composite after micro-arc oxidation. Trans Nonferrous Meta Soc China. 2013;23(2):347.

Zhou XS, Zhang XY, Wu DF. Effects of nano-SiO2 in electrolytes on surface properties of micro-arc oxidation ceramic coatings formed on new casting aluminum alloy. Adv Mater Res. 2012;581–582(1):368.

Acknowledgements

This work was financially supported by the International Technology Cooperation Plan in Guizhou Province (No.2012-7001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, TY., Zhang, XY., Huang, X. et al. Microstructure and properties of microarc oxidation coating formed on aluminum alloy with compound additives nano-TiO2 and nano-ZnO. Rare Met. 37, 976–982 (2018). https://doi.org/10.1007/s12598-017-0948-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0948-z