Abstract

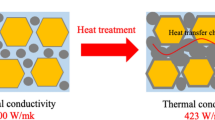

This study was pertained to the effects of Ti coating on diamond surfaces and Si addition into Al matrix on the thermal conductivity (TC) and the coefficient of thermal expansion (CTE) of diamond/Al composites by pressure infiltration. The fracture surfaces, interface microstructures by metal electro-etching and interfacial thermal conductance of the composites prepared by two methods were compared. The results reveal that Ti coating on diamond surfaces and only 12.2 wt% Si addition into Al matrix could both improve the interfacial bonding and increase the TCs of the composites. But the Ti coating layer introduces more interfacial thermal barrier at the diamond/Al interface compared to adding 12.2 wt% Si into Al matrix. The diamond/Al composite with 12.2 wt% Si addition exhibits maximum TC of 534 W·m−1·K−1 and a very low CTE of 8.9 × 10−6 K−1, while the coating Ti-diamond/Al composite has a TC of 514 W·m−1·K−1 and a CTE of 11.0 × 10−6 K−1.

Similar content being viewed by others

References

Yang ZL, Wang LG, Wang LM, He XB, Qu XH, Liu RJ, Hu HF. Microstructure and graphitization behavior of diamond/SiC composites fabricated by vacuum vapor reactive infiltration. Rare Met. 2015;34(6):400.

German RM, Hens KF, Johnson JL. Powder metallurgy processing of thermal management materials for microelectronic applications. Int J Powder Metal. 1994;30(2):205.

Beffort O, Khalid FA, Weber L, Ruch P, Klotz UE, Meier S, Kleiner S. Interface formation in infiltrated Al(Si)/diamond composites. Diam Relat Mater. 2006;15(9):1250.

Ruch PW, Beffort O, Kleiner S, Weber L, Uggowitzer PJ. Selective interfacial bonding in Al(Si)-diamond composites and its effect on thermal conductivity. Compos Sci Technol. 2006;66(15):2677.

Khalida FA, Beffortb O, Klotza UE, Kellera BA, Gassera P. Microstructure and interfacial characteristics of aluminium-diamond composite materials. Diam Relat Mater. 2004;13(3):393.

Weber L, Tavangar R. Diamond-based metal matrix composites for thermal management made by liquid metal infiltration-potential and limits. Adv Mater Res. 2009;59(59):111.

Weber L, Tavangar R. On the influence of active element content on the thermal conductivity and thermal expansion of Cu–X (X = Cr, B) diamond composites. Scrip Mater. 2007;57(11):988.

Johnson WB, Sonuparlak B. Diamond/Al metal matrix composites formed by the pressure infiltration process. J Mater Res. 1993;8(5):1169.

Schubert T, Ciupinski L, Zielinski W, Michalski A, Weißgarber T, Kieback B. Interfacial characterization of Cu/diamond composites prepared by powder metallurgy for heat sink applications. Scrip Mater. 2008;58(4):263.

Pech-Canul MI, Katz RN, Makhlouf MM. Optimum conditions for pressureless infiltration of SiCp performs by aluminum alloys. J Mater Process Technol. 2000;108(1):68.

Lee HS, Hong SH. Pressure infiltration casting process and thermophysical properties of high volume fraction SiCp/Al metal matrix composites. Mater Sci Technol. 2003;19(8):1057.

Schubert TH, Trindade B, Weisgarber T, Kieback B. Interfacial design of Cu based composites prepared by powder metallurgy for heat sink applications. Mater Sci Eng, A. 2008;475(1–2):39.

Xue C, Yu JK. Enhanced thermal conductivity in diamond/aluminum composites: comparison between the methods of adding Ti into Al matrix and coating Ti onto diamond surface. Surf Coat Technol. 2013;217(2):46.

Feng H, Yu JK, Tan W. Microstructure and thermal properties of diamond/aluminum composites with TiC coating on diamond particles. Mater Chem Phys. 2010;124(1):851.

Mizuuchi K, Inoue K, Agari Y, Morisada Y, Sugioka M, Itami M, Kawahara M, Makino Y. Thermal conductivity of diamond particle dispersed aluminum matrix composites produced in solid-liquid co-existent state by SPS. Compos Part B. 2011;42(5):1029.

Mizuuchi K, Inoue K, Agari Y, Morisada Y, Sugioka M, Tanaka M, Takeuchi T, Tani J, Kawahara M, Makino Y. Processing of diamond particle dispersed aluminum matrix composites in continuous solid-liquid co-existent state by SPS and their thermal properties. Compos Part B. 2011;42(4):825.

Ren SB, Shen XY, Guo CY, Liu N, Zang JB, He XB, Qu XH. Effect of coating on the microstructure and thermal conductivities of diamond-Cu composites prepared by powder metallurgy. Compos Sci Technol. 2011;71(13):1550.

Ekimov EA, Suetin NV, Popovich AF, Ralchenko VG. Thermal conductivity of diamond composites sintered under high pressures. Diam Relat Mater. 2008;17(4):838.

Ren SB, He XB, Qu XH, Li Y. Effect of controlled interfacial reaction on the microstructure and properties of the SiCp/Al composites prepared by pressureless infiltration. J Alloys Compd. 2008;455(1):424.

Swartz ET, Pohl RO. Thermal boundary resistance. Rev Mod Phys. 1989;61(3):605.

Chu K, Jia CC, Liang XB, Chen H, Gao WJ, Guo H. Modeling the thermal conductivity of diamond reinforced aluminium matrix composites within homogeneous interfacial conductance. J Mater Des. 2009;30(10):4311.

Dyck JS, Chen W, Uher C. Heat transport in Sb2-x V x Te3 single crystals. Phys Rev B. 2002;66(12):125.

Hasselman DP, Johnson LF. Effective thermal conductivity of composites with interfacial thermal barrier resistance. J Compos Mater. 1987;21(6):508.

Lee HS, Hong SH. Pressure infiltration casting process and thermophysical properties of high volume fraction SiCp/Al metal matrix composites. Mater Sci Technol. 2003;19(8):1057.

Kerner EH. The elastic and thermoelastic properties of composite media. Proc Phys Soc. 1956;69(8):808.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51274040) and the Fundamental Research Funds for the Central Universities (No. FRF-TP-10-003B).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, CY., He, XB., Ren, SB. et al. Thermal properties of diamond/Al composites by pressure infiltration: comparison between methods of coating Ti onto diamond surfaces and adding Si into Al matrix. Rare Met. 35, 249–255 (2016). https://doi.org/10.1007/s12598-015-0672-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0672-5