Abstract

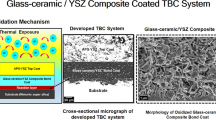

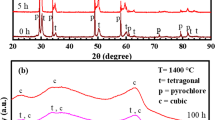

Thermal barrier coatings (TBCs) protection is widely used to prolong the lifetime of turbine components. The outermost layer of TBCs is ceramic layer, whose function is heat insulation, and the main composition of the ceramic layer is ZrO2. In this study, the micro-ZrO2 and the nano-ZrO2 doped with 10 wt% CeO2 as well as micro-ZrO2 and nano-ZrO2 were prepared by air plasma spraying (APS) to study the advantages of the addition of rare earth element. The effect of CeO2 on the phase transformation of ZrO2 was studied. The results show that there are few cracks in micro- and nano-ZrO2 doped with 10 wt% CeO2, and rare earth oxides can affect the phase transformation significantly. The morphologies, hardness and elastic modulus of the four ceramic layers were also discussed.

Similar content being viewed by others

References

Zhou YCH, Liu XQ, Li Y, Wu DJ, Mao WG. Failure mechanisms and life prediction of thermal barrier coatings. J Solid Mech. 2010;31(5):504.

Zhong XH, Zhao HY, Zhou XM, Liu CG, Wang L, Shao F, Yang K, Tao SY, Ding CX. Thermal shock behavior of toughened gadolinium zirconate/YSZ double-ceramic-layered thermal barrier coating. J Alloys Compd. 2014;593(25):50.

Naga SM. Ceramic matrix composite thermal barrier coatings for turbine parts. Adv Ceram Matrix Compos. 2014;. doi:10.1533/9780857098825.3.524.

Su L, Wu HC, Lei XG, Liu L. Failure analysis on TBCs with thin bond coating in EB-PVD process. Mater Heat Treat. 2011;40(24):243.

Hao YF, Tang WJ, Wang HY, Chen H. The analysis of the organizational structure and thermal shock performance of the nano zirconia structure thermal barrier coating. Weld Technol. 2010;31(3):109.

Chen ZB, Wang ZG, Zhu SJ. Failure behavior of thermal barrier coatings on cylindrical superalloy tube was investigated under thermomechanical fatigue. Acta Metall Sin. 2013;26(4):404.

Li MH, Sun XF, Zhang CY, Hu WY, Guan HG, Hu ZL. Structure and morphology changes of Al2O3 membrane by the oxidation of spring NiCrAlY. Corros Sci Prot Technol. 2010;31(3):142.

Liu RX, Guo F, Li PF, Liu L, Wang S, Zhao RR, Zhang YL. Effect of RE element in magnesium alloy on surface morphology and structure of ceramic coating by micro-arc oxidation. Heat Treat Met. 2008;33(11):70.

Nicholls JR, Lawson KJ, Johnstone A, Rickerby DS. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf Coat Technol. 2002;151–152:383.

Masayuki ARAI. Inelastic constitutive equation of plasma-sprayed ceramic thermal barrier coatings. Acta Metall Sin (Engl Lett). 2011;24(2):161.

Dai H, Zhong X, Li J, Zhang Y, Meng J, Cao X. Thermal stability of double-ceramic-layer thermal barrier coatings with various coating thickness. Mater Sci Eng A. 2006;433(1–2):1.

Matsumotoa M, Aoyama K, Matsubar H. Thermal conductivity and phase stability of plasma sprayed ZrO2–Y2O3–La2O3 coatings. Surf Coat Technol. 2005;194(1):31.

Matsumoto M, Yamaguchi N, Matsubara H. Low thermal conductivity and high temperature stability of ZrO2–Y2O3–La2O3 coatings produced by electron beam PVD. Scr Mater. 2004;50(6):867.

Chen D, Chu ZM, Zhang Q. Analysis of several test methods about heat insulation capabilities of ceramic thermal barrier coatings. Phys Procedia. 2013;50:248.

Cao XQ, Vassen R, Tietz F, Stoever D. New double-Ceramic-layer thermal barrier coatings based on zirconia-rare earth composite oxides. J Eur Ceram Soc. 2006;26(3):247.

Dai H, Zhong XH, Li JY, Meng J, Cao XQ. Neodymium–cerium oxide as new thermal barrier coating material. Surf Coat Technol. 2006;201(6):2527.

Zhong XH, Xu ZH, Zhang YF, Zhang JF, Cao XQ. Phase stability and thermophysical properties of neodymium cerium composite oxide. J Alloys Compd. 2009;469(1–2):82.

Bahadori E, Javadpour S, Shariat MH, Mahzoon F. Preparation and properties of ceramic Al2O3 coating as TBCs on MCrAlY layer applied on Inconel alloy by cathodic plasma electrolytic deposition. Surf Coat Technol. 2013;228(1):S611.

Han M, Huang JH, Chen SH. Behavior and mechanism of the stress buffer effect of the inside ceramic layer to the top ceramic layer in a double-ceramic-layer thermal barrier coating. Ceram Int. 2014;40(2):2901.

Chen YX, Liang XB, Bai JY, Xu BS. High velocity electric arc sprayed Fe–Al–Nb–B composite coating and its wear behavior. Acta Metall Sin (Engl Lett). 2011;26(3):313.

Richer P, Zuniga A, Yandouzi M, Jodoin B. CoNiCrAlY microstructural changes induced during cold gas dynamic spraying. Surf Coat Technol. 2008;203(3–4):364.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51371173), the Natural Science Foundation of Liaoning Province (No. 2013024011) and the Doctor Start-Up Fund of Liaoning Province (No. 20121063).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, B., Li, Y., Zhang, HY. et al. Phase transformation of ZrO2 doped with CeO2 . Rare Met. 37, 66–71 (2018). https://doi.org/10.1007/s12598-015-0552-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0552-z