Abstract

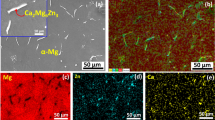

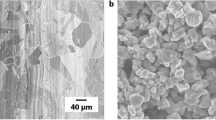

NiCr–Cr3C2 metal–ceramic composite coating is commonly produced on metal substrate by laser cladding to be used as wear-resistant coating under medium- or high-temperature working conditions. The coating has high hardness, generally over three times that of the substrate. In order to make the hardness increase gradually from substrate to coating surface, the nickel-based alloy Ni45 was chosen as the transition layer and NiCr–Cr3C2 coating was indirectly cladded on 20Cr2Ni4A substrate. Microstructure and composition of the coating were characterized by scanning electron microscope (SEM), energy-dispersive spectroscopy (EDS) and X-ray diffraction (XRD). Microhardness of the cross section of the coating was measured. Friction and wear behavior of NiCr–Cr3C2 coating and substrate were investigated through sliding against the SiC ball at 20, 100 and 300 °C. The morphologies of worn surfaces were analyzed by SEM and EDS. The results show that the hardness of Ni45 transition layer is between that of the substrate and NiCr–Cr3C2 coating, which avoids hardness jump and stress concentration of the coating. NiCr–Cr3C2 coating contains hard phases of Cr3C2 and Cr7C3 which enhance the wear resistance. With the temperature increasing, friction coefficient and wear rate of the substrate increase significantly. Compared with the substrate, NiCr–Cr3C2 coating has lower friction coefficient and wear rate at 100 and 300 °C, which verifies the good wear resistance of NiCr–Cr3C2 coating.

Similar content being viewed by others

References

Wu X, Guo ZM, Wang HB, Song XY. Mechanical properties of WC–Co coatings with different decarburization levels. Rare Metals. 2014;33(3):313.

Xie ZQ, Huang HY, Lu F, Zhao YQ, Wang HJ. Study on high temperature performances of NiCr–Cr3C2 coatings by supersonic plasma spraying. Rare Met Mater Eng. 2012;41(S2):726.

Zhou R, Jia DC, Yang Y, Yang ZH, Zhou Y. Effect of Cr contents on microstructure and mechanical properties of (TiBw + TiCp)/(Ti−4.0Fe−7.3Mo−xCr) composites. Chin J Rare Met. 2012;36(4):552.

Sun GF, Zhang YK, Liu CS, Luo KY, Tao XQ, Li P. Microstructure and wear resistance enhancement of cast steel rolls by laser surface alloying NiCr–Cr3C2. Mater Des. 2010;31(6):2737.

Huang CB, Du LZ, Zhang WG. Preparation and characterization of atmospheric plasma-sprayed NiCr/Cr3C2–BaF2–CaF2 composite coating. Surf Coat Technol. 2009;203(20–21):3058.

Poirier D, Legoux JG, Lima RS. Engineering HVOF-sprayed Cr3C2–NiCr coatings: the effect of particle morphology and spraying parameters on the microstructures, properties, and high temperature wear performance. J Therm Spray Technol. 2013;22(2–3):280.

Liu XT, Lei WB, Li J, Ma Y, Wang WM, Zhang BH, Liu CS, Cui JZ. Laser cladding of high-entropy alloy on H13 steel. Rare Metals. 2014;33(6):727.

Wang LQ, Zhou JS, Yu YJ, Guo C, Chen JM. Effect of powders refinement on the tribological behavior of Ni-based composite coatings by laser cladding. Appl Surf Sci. 2012;258(17):6697.

Lu YJ, Wang XN, Sun Q. Microstructure and properties of laser remelting plasma-sprayed NiCr–Cr3C2 coatings. J Ceram. 2011;32(3):368.

Li J, Zeng KL, Gao F. The effects of Cr3C2–25NiCr on microstructure and properties of iron based laser clad layer. Therm Spray Technol. 2012;4(1):36.

Liu XB, Liu HQ, Meng XJ, Yang MS, Shi SH, Fu GY, Sun CF, Wang MD, Qi LH. High temperature tribological behaviors of laser cladding NiCr/Cr3C2–WS2 self-lubrication wear-resistant coating. J Mater Eng. 2013;11:26.

Yang MS, Liu XB, Fan JW, He XM, Shi SH, Fu GY, Wang MD, Chen SF. Microstructure and wear behaviors of laser clad NiCr/Cr3C2–WS2 high temperature self-lubricating wear-resistant composite coating. Appl Surf Sci. 2012;258(8):3757.

Chen SF, He XM, Yang MS, Wang MD, Liu XB. NiCr/Cr3C2–WS2–CaF2 wear resistant composite coatings prepared by laser cladding. Trans Mater Heat Treat. 2012;33(10):21.

Liu HQ, Liu XB, Meng XJ, Sun CF, Wang MD, Shi GL, Wu SH. Study on γ-NiCrAlTi/TiC + TiWC2/CrS + Ti2CS high temperature self-lubricating wear resistant composite coating on Ti–6Al–4V by laser cladding. Chin J Lasers. 2014;41(3):0303005.

He XM, Liu XB, Wang MD, Yang MS, Shi SH, Fu GY, Chen SF. Elevated temperature dry sliding wear behavior of nickel-based composite coating on austenitic stainless steel deposited by a novel central hollow laser cladding. Appl Surf Sci. 2011;258(1):535.

Yu YJ, Zhou JS, Chen JM, Zhou HD, Guo C. Microstructure and tribological behavior of laser cladding NiCr/Cr3C2–Ag–BaF2/CaF2 self-lubrication wear resistant metal matrix composite coating. Chin Surf Eng. 2010;23(3):64.

Yu T, Deng QL, Zhang W, Dong G, Yang JG. Study on cracking mechanism of laser clad NiCrBSi coating. J Shanghai Jiaotong Univ. 2012;46(7):1043.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51275020) and the National Defense Pre-Research Foundation of China (No. 9140A18020212HK01210).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zang, CC., Wang, YZ., Zhang, YD. et al. Microstructure and wear-resistant properties of NiCr–Cr3C2 coating with Ni45 transition layer produced by laser cladding. Rare Met. 34, 491–497 (2015). https://doi.org/10.1007/s12598-015-0492-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0492-7