Abstract

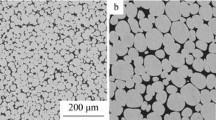

Wf/Cu82Al10Fe4Ni4 composite was fabricated by means of infiltration casting. By the microstructure observation of the composite with the aid of scanning electron microscopy (SEM) and transmission electron microscopy (TEM), it can be found that there are (Fe, Ni), AlFe, Al3Ni, and Cu3Al precipitated phases existing in the matrix alloy. By two-stage light gas gun, Wf/Cu82Al10Fe4Ni4 composite hypervelocity projectile into concrete target test with the speed of 2.2 km·s−1 is finished. By microstructure observation, it can be found that the failure mode of Wf/Cu82Al10Fe4Ni4 composite projectile during penetration is the rapid peeling of tungsten fibers from the projectile, which makes the projectile display good self-sharpening property. Meanwhile, it can be found that microstructure morphology change of Wf/Cu82Al10Fe4Ni4 composite occurs after hypervelocity impact. The density of dislocations around the large-dimensional (Fe, Ni), AlFe, Al3Ni, and Cu3Al precipitated phases in the matrix alloy rises sharply. At the same time, there are large-dimensional deformed twins existing in local regions and stacking faults existing inside the twins.

Similar content being viewed by others

References

Zou DL, Zhen L, Zhu Y, Xu CY, Shao WZ, Pang BJ. Deformed microstructure evolution in AM60B Mg alloy under hypervelocity impact at a velocity of 5 km·s−1. Mater Des. 2010;31(8):3708.

Pappu S, Kennedy C, Murr LE, Magness LS, Kapoor D. Microstructure analysis and comparison of tungsten alloy rod and [001] oriented columnar-grained tungsten rod ballistic penetrators. Mater Sci Eng A. 1999;262(1):115.

Randrianarivony FM, Lair S, Quinones SA, Murr LE. Experimental observations and computer simulations of spherical aluminum-alloy projectiles impacting plane limestone targets. J Mater Sci. 2002;37(24):5197.

Liu JX, Li SK, Fan AL, Sun HC. Effect of fibrous orientation on dynamic mechanical properties and susceptibility to adiabatic shear band of tungsten heavy alloy fabricated through hot-hydrostatic extrusion. Mater Sci Eng A. 2008;487(1–2):235.

Conner RD, Dandliker RB, Johnson WL. Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5Ni10Be22.5 metallic glass matrix composites. Acta Mater. 1998;46(17):6089.

Zhang HF, Li H, Wang AM, Fu HM, Ding BZ, Hu ZQ. Synthesis and characteristics of 80 vol% tungsten (W) fibre/Zr based metallic glass composite. Intermetallics. 2009;17(12):1070.

Kim HG, Kim KT. Densification behavior of tungsten-fiber-reinforced copper powder compacts under hot isostatic pressing. Int J Mech Sci. 2000;42(7):1339.

Manel RR, Jan O. Microstructure and texture evolution during the drawing of tungsten wires. Eng Fract Mech. 2009;76(10):1485.

Schade P. 100 years of doped tungsten wire. Int J Refract Met Hard Mater. 2010;28(6):648.

Schade P. Wire drawing failures and tungsten fracture phenomena. Int J Refract Met Hard Mater. 2006;24(4):332.

Ma WF, Kou HC, Chen CS, Li JS, Chang H, Zhou L, Fu HZ. Compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Mater Sci Eng A. 2008;486(1–2):308.

Qiu KQ, Wang AM, Zhang HF, Ding BZ, Hua ZQ. Mechanical properties of tungsten fiber reinforced ZrAlNiCuSi metallic glass matrix composite. Intermetallics. 2002;10(11–12):1283.

Zuo M, Zhang ZS, Teng XY, Geng HR. Refinement of primary Si in Cu-50Si alloys with novel Al-Zr-P master alloy. Rare Met. 2013;32(3):252.

Guo HP, Chen WG, Zhang H. Characterization of W80Cu20 alloy sheet prepared by hot-rolling. Rare Met. 2013;32(6):569.

Hong SH, Kim BK, Munir ZA. Synthesis and consolidation of nanostructured W-10-40 wt% Cu powders. Mater Sci Eng A. 2005;405(1–2):325.

Li R, Chen WG, Wang L. Effects of fiber distribution on density and electrical conductivity of tungsten fiber reinforced Cu-based composite material. Chin J Rare Met. 2013;37(2):243.

Zhao D, Ding YG. Simplified nonlinear theory of the dielectric loaded rectangular Cerenkov maser. Chin Phys B. 2012;21(9):094102.

Zhou LP, Wang MP, Wang R, Li Z, Zhu JJ, Peng K, Li DY, Li SL. Enhanced adhesion of Cu-W thin films by ion beam assisting bombardment implanting. Trans Nonferr Met Soc China. 2008;18(2):372.

Yong MS, Clegg AJ. Process optimizations for a squeeze cast magnesium alloy metal matrix composite. J Mater Process Technol. 2005;168(2):262.

Herrmann A, Schmid K, Balden M, Bolt H. Interfacial optimization of tungsten fibre-reinforced copper for high-temperature heat sink material for fusion application. J Nucl Mater. 2009;386–388:453.

Xue Q, Cerreta EK, Gray GT. Microstructural characteristics of post-shear localization in cold-rolled 316L stainless steel. Acta Mater. 2007;55(2):691.

Meyers MA, Xu YB, Xue Q, Pérez-Prado MT, Mcnelley TR. Microstructural evolution in adiabatic shear localization in stainless steel. Acta Mater. 2003;51(5):1307.

Lins JFC, Sandim HRZ, Kestenbach HJ, Raabe D, Vecchio KS. A microstructural investigation of adiabatic shear bands in an interstitial free steel. Mater Sci Eng A. 2007;457(1–2):205.

Murr LE, Meyers MA, Niou CS, Chen YJ, Pappu S, Kennedy C. Shock-induced deformation twinning in tantalum. Acta Mater. 1997;45(1):157.

Meyers MA, Andrade RU, Chokshi HA. The effect of grain size on the highstrain, high-strain-rate behavior of copper. Metall Mater Trans A. 1995;26:2881.

Gu Y, Chao YS, Zhang YH. Soft magnetic properties of amorphous Fe52Co34Hf7B6Cu1 alloy treated by pulsed magnetic field and annealing. Chin Phys B. 2012;21(12):127805.

Acknowledgments

This study was financially supported by the Fundamental Research Funds for the Central Universities (No. DL12BB04) and the National Natural Science Foundation of China (Nos. 31200434 and 31370566).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Z., Yang, CM., Liu, QJ. et al. Damage behavior of tungsten fiber-reinforced copper matrix composite after high-speed impact. Rare Met. 33, 330–336 (2014). https://doi.org/10.1007/s12598-014-0309-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0309-0