Abstract

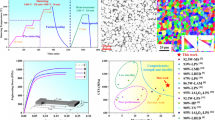

Nano-Y2O3 and nano-CeO2 of different weight ratio mixed with deionizing water were doped into MoO2 powder by liquid–solid doping method. The diameter 1.80 and 0.18 mm alloy wires of Mo–0.3Y, Mo–0.3Ce, and Mo–0.15Y–0.15Ce were prepared through reduction, isostatic pressing, sintering, and drawing. Tensile properties, second phase microstructure and fracture surface appearance of wires were analyzed. The better refining effect for Mo alloy powder can be gotten after two kinds of nanoparticle oxide doped into MoO2 than only one doped. Nano-Y2O3 and nano-CeO2 have different influences on sintering process. For nano-CeO2, the constraining effect of grain growth focuses on the initial sintering stage, nano-Y2O3 plays refining grains roles in the later densification stage. Nano-Y2O3 is undistorted and keeps intact in the process of drawing; and nano-CeO2 is elongated and broken into parts in the drawing direction. The strengthening effect of nano-Y2O3 and nano-CeO2 keeps the finer grains and superior tensile properties for Mo–0.15Y–0.15Ce wire.

Similar content being viewed by others

References

Wren C, Gao MC, Doğan ÖN, Paul K. Thermodynamic assessment of Mo–Ce and Mo–Y systems. J Phase Equilib Diffus. 2010;31(5):414.

Bernd F, Dietmar F, Jan CC. Manufacture and properties of Mo–Re alloys. In: International conference on powder metallurgy particulate materials; 2000. 8097.

Schimpf C, Mrotzek T, Martin U. Thermally activated flow stress component of the Mo alloy TZM determined by constitutive models. In: 16th international plansee seminar, vol. 2; 2005. 485.

Shields Jr JA, Lipetzky P, Mueller AJ. Fracture toughness of 6.4 mm (0.25 inch) arc-cast molybdenum and molybdenum–TZM plate at room temperature and 300°C. In: 15th international plansee seminar, vol. 4; 2001. 187.

Ren BJ. Study on preparation technology and property of La–Mo alloy powder. Xi’an: Xi’an University of Architecture and Technology; 2009. 35.

Morito F, Chakin VP, Saito H. Effects of rhenium or boron addition on microstructural behavior and mechanical properties of molybdenum alloys. In: 16th international plansee seminar, vol. 2; 2005. 293.

Yang DX, Wang P, Wei SZ, Li JW, Xu LJ. Study on structures and properties of Mo products doped with rare earth. Chin Rare Earths. 2011;32(6):66.

Fu XJ. Particle size control of Mo powder with rare-earth element. Chin J Rare Met. 2003;27(1):202.

Ge X, Yan MZ, Zhang HL. Temperature programmed reduction and reduction kinetics of Mo Ce oxides. Chin J Inorg Chem. 1997;13(1):24.

Cheng HC, Liu PP, Fan JL, Tian JM, Li PF. Influence of Y2O3 on sintering performance and micro-structure of ultrafine Mo composite powders. Mater Sci Eng Powder Metall. 2011;16(3):355.

Kazushige K, Tadayuki FJ. Secondary grain growth behavior of dispersion strengthened molybdenum sheet. Powder Powder Metall. 2003;50(1):3.

Wang L, Sun J, Sun YJ, Luo JH, Wang JW. Effects of doping methods on microstructure and mechanical properties of Mo–La2O3. Rare Met Mater Eng. 2007;26(10):1827.

Sun Z, Jiang L, Ying PZ. Failure Analysis: Fundamentals and Applications. Beijing: Machinery Industry Press; 2009. 105.

Duan SH, Zhang GS, Wei SZ, Peng GH, Xu LJ. High temperature tensile properties of M–La2O3 sheet. Trans Mater Heat Treat. 2011;32(8):30.

Zhang GJ, Lin XH, Wang RH. Tensile properties and strengthening mechanisms of Mo–Si alloy. Int J Refract Met Hard Mater. 2011;29(5):608.

Xu JH, Leonhardt T, Farrell J, Effgen M, Zhai M. Anomalous strain-rate effect on plasticity of a Mo–Re alloy at room temperature, Mater Sci Eng A Struct Mater Prop Microstruct Process. 2008;479(1–2):76.

Acknowledgments

This project was financially supported by the National Tungsten and Molybdenum Value-added Utilization Technology Industry Development (No. 2012BAE06B02) and Shanxi Province Science and Technology Innovation Plan (No. 2012KTCQ01-08).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, RZ., Wang, KS., Feng, PF. et al. Microstructure and tensile properties of Mo alloy synthetically strengthened by nano-Y2O3 and nano-CeO2 . Rare Met. 33, 58–64 (2014). https://doi.org/10.1007/s12598-013-0120-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0120-3