Abstract

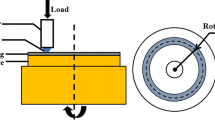

The objective of this research is to prepare specially designed surface texture on hard steel surface by electrochemical micromachining (EM) and to incorporate electroless plated Ag/MoS2 solid lubricant coating into the dimples of EM textured steel surface to effectively reduce friction and wear of steel-steel contacts. The friction and wear behavior of the Ag/MoS2 solid lubricant coating on EM textured steel surface was evaluated in relation to the size and spacing of the dimples thereon. The microstructure of as-plated Ag/MoS2 solid lubricant coating and the morphology and elemental composition of the worn coating surface and counterface steel surface were analyzed by means of optical microscopy, scanning electron microscopy, and energy dispersive spectrometry. It is found that electroless plated Ag/MoS2 coating is able to greatly reduce the friction and wear of the EM textured steel disc coupled with GCr15 steel ring, mainly because of the formation of solid self-lubricating layer on the EM textured steel surface and of transferred lubricating film on counterface steel surface. The diameter and spacing of the dimples are suggested as 500 μm for acquiring the best wear resistance of the hard steel discs after electrochemical micromachining treatment and electroless plating of Ag/MoS2 solid lubricating coating.

Similar content being viewed by others

References

Waldemar Koszela, Pawel Pawlus, and Lidia Galda, The effect of oil pockets size and distribution on wear in lubricated sliding, Wear, 2007, 263(7–12): 1585.

Etsion I., State of the art in laser surface texturing, Journal of Tribology, 2005, 127(1): 248.

Rajurkar K.P., Levy G., Malshe A., Sundaram M.M., McGeough J., Hu X., Resnick R., and DeSilva A., Micro and nano machining by electro-physical and chemical processes, Manufacturing Technology, 2006, 55(2): 643.

Natsu W., Ooshiro S., and Kunieda M., Research on generation of three-dimensional surface with micro-electrolyte jet machining, Journal of Manufacturing Science and Technology, 2008, 1(1): 27.

Natsu W., Ikeda T., and Kunieda M., Generating complicated surface with electrolyte jet machining, Precision Engineering, 2007, 31(1): 33.

Kim B.H., Na C.W., Lee Y.S., Choi D.K., and Chu C.N., Micro electrochemical machining of 3d microstructure using dilute sulfuric acid, Manufacturing Technology, 2005, 54(1): 191.

Datta M., Landolt D., Fundamental aspects and applications of electrochemical microfabrication, Electrochimica Acta, 2000, 45(15–16): 2535.

Zhu D., Qu N.S., Li H.S., Zeng Y.B., Li D.L., and Qian S.Q., Electrochemical micromachining of microstructures of micro hole and dimple array, Manufacturing Technology, 2009, 58(1): 177.

Rapoport L., Moshkovich A., Perfilyev V., Lapsker I., Halperin G., Itovich Y., and Etsion I., Friction and wear of MoS2 films on laser textured steel surfaces, Surface and Coatings Technology, 2008, 202(14): 3332.

Voevodin A.A., Bultman J., and Zabinski J.S., Investigation into three-dimensional laser processing of tribological coatings, Surface and Coatings Technology, 1998, 107(1): 12.

Voevodin A.A., and Zabinski J.S., Laser surface texturing for adaptive solid lubrication, Wear, 2006, 261(11–12): 1285.

Wang J.S., Meng H.M., Yu H.Y., Fan Z.S., and Sun D.B., Surface hardening of Fe-based alloy powders by Nd:YAG laser cladding followed by electrospark deposition with WC-Co cemented carbide, Rare Metals, 2010, 29(4): 380.

Hilton M.R., and Fleischauer P.D., Applications of solid lubricant films in spacecraft, Surface and Coatings Technology, 1992, 54(55): 435.

Xu J., Zhua M.H., Zhou Z.R., Kapsab Ph, and Vincentb L., An investigation on fretting wear life of bonded MoS2 solid lubricant coatings in complex conditions, Wear, 2003, 255(1–6): 253

Miremadi Bijan K, Colbow Konrad, and Morrison S Roy, A molybdenum disulfide magnetic solid lubricant for ferromagnetic surfaces, Journal of Applied Physics, 1997, 82(5): 2636.

Roberts E.W., Williams B.J., and Ogilvy J.A., The effect of substrate surface roughness on the friction and wear of sputtered MoS2 films, Journal of Physics D-applied Physics, 1992, 25(1A): A65.

Cunningham J.M., Ford A.J., Ogilvy J.A., and Roberts E.W., Interpretation of friction and wear properties of MoS2 coated steel substrates, Wear, 1994, 177(1): 93.

Pettersson U., and Jacobson S., Influence of surface texture on boundary lubricated sliding contacts, Tribology International, 2003, 36(11): 857.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, Z., Liu, M., Xiong, D. et al. Surface texturing for adaptive Ag/MoS2 solid lubricant plating. Rare Met. 31, 560–565 (2012). https://doi.org/10.1007/s12598-012-0558-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-012-0558-8