Abstract

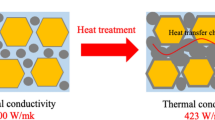

The thermal conductivity of diamond hybrid SiC/Cu, diamond/Cu and SiC/Cu composite were calculated by using the extended differential effective medium (DEM) theoretical model in this paper. The effects of the particle volume fraction, the particle size and the volume ratio of the diamond particles to the total particles on the thermal conductivity of the composite were studied. The DEM theoretical calculation results show that, for the diamond hybrid SiC/Cu composite, when the particle volume fraction is above 46% and the volume ratio of the diamond particles to the SiC particles is above 13:12, the thermal conductivity of the composite can reach 500 W·m−1·K−1. The thermal conductivity of the composite has little change when the particle size is above 200 μm. The experimental results show that Ti can improve the wettability of the SiC and Cu. The thermal conductivity of the diamond hybrid SiCTi/Cu is almost two times better than that of the diamond hybrid SiC/Cu. It is feasible to predict the thermal conductivity of the composite by DEM theoretical model.

Similar content being viewed by others

References

Schelling P.K., Shi L., and Goodson K.E., Managing heat for electronics, Materials Today, 2005, 6: 30.

Schubert Th., Trindade B. and Weißgärber T., Interfacial design of Cu-based composites prepared by powder metallurgy for heat sink applications, Mater. Sci. Eng. A, 2008, 475: 39.

He X.B., Qu X.H., and Ren S.B., Net-shape forming of composite packages with high thermal conductivity, Science in China Series E: Technological Sciences, 2009, 52(1): 238.

Zweben C., Thermal management and electronic packaging applications, ASM., 2001, 21: 1078.

Chung D.D.L., Materials for thermal conduction, Applied Thermal Engineering, 2001, 21: 1593.

Zweben C., Advances in LED packaging and thermal management materials, SPIE., 2008, 691018: 1.

Zhang X.M,, Guo H., and Yin F.Z., Interfacial microstructure and properties of diamond/Cu-xCr composites for electronic packaging applications, Rare Metals, 2011, 30(1): 94.

Shang Q.L., Tao J.M., and Xu M.C., Research progress of diamond-cu composite material for electronic packaging, Electronics Process Technology, 2009, 30(1): 5.

Kidalov S.V., and Shakhov F.M., Thermal conductivity of diamond composite, Materials, 2009, (2): 2467.

Prieto R., Molina J.M., Narciso J., and Louis E., Fabrication and properties of graphite flakes/metal composites for thermal management applications, Scripta Materialia, 2008, 59: 11.

Molina J.M., Narciso J., Weber L., Mortensen A., and Louis E., Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution, Materials Science and Engineering A, 2008, 480: 483.

Chu K., Jia C.C., and Liang X. B. Experimental and modeling study of the thermal conductivity of SiCp/Al composites with bimodal size distribution, J. Mater. Sci., 2009, 44: 4370.

Molina J.M., Rhême M., and Carron J., Thermal conductivity of aluminum matrix composites reinforced with mixtures of diamond and SiC particles, Scripta Materialia, 2008, 58: 393.

Davidson H.L., Copper-diamond composites substrates for electronic components, IEEE., 1995: 538.

Zhu D.Z., Wu G.H., and Chen G.Q., Fabrication and properties of SiC/Cu composites for electronic packaging, [in] IEEE, 6 th International Conference on Electronic Packaging Technology, Shenzhen, 2005: 191.

Norris A.N. Callegari A.T., and Sheng P., A generalized differential effective medium theory, J. Mech. Phys. Solids, 1985, 53: 525.

Ervin V.J., Klett J.W., and Mundt C.M., Estimation of the thermal conductivity of composites, J. Mater. Sci., 1999, 34: 3545.

Bruggeman D.A.G., Effective medium model for the optical properties of composite materials, Ann. Phys. Leipzig, 1935, 24: 636.

Young T.H., Chuang W.Y., and Hsieh M.Y., Assessment and modeling of poly (vinyl alcohol) bioartificial pancreas in vivo, Biomaterials, 2002, 23(16): 3495.

Xiu Z.Y., Thermal Properties and Mechanical Properties of SiP/LD11 Composite Materials for Electronic Packaging [Dissertation], Harbin Institute of Technology, Harbin, 2003: 15.

Molina J.M., Prieto R., and Narciso J., The effect of porosity on the thermal conductivity of Al-12 wt.% Si/SiC composites, Scripta Materialia, 2009, 60: 582.

Swartz E.T., and Pohl R.O., Thermal boundary resistance, Rev. Mod. Phys., 1989, 61: 605.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, Y., Guo, H., Yin, F. et al. Microstructure and thermal conductivity of copper matrix composites reinforced with mixtures of diamond and SiC particles. Rare Metals 31, 58–63 (2012). https://doi.org/10.1007/s12598-012-0463-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-012-0463-1