Abstract

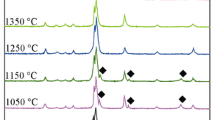

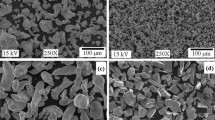

Ti3AlC2 has the properties of ceramics and metals. These excellent properties indicate that Ti3AlC2 is a very promising material to extensive applications. Ti3AlC2 ceramic material was prepared by mechanical alloying. The effects of milling time and sintering temperature on the fracture, microstructure and mechanical properties of Ti3AlC2 ceramic material were analyzed by laser particle analyzer, X-ray diffraction, and scanning electron microscopy. The experimental results showed that Ti3AlC2 had the best comprehensive properties after the composite powder was milled for 3 h and sintered at 1630°C for 2 h. The relative density, bending strength, and hardness of the sample reached 92.23%, 345.2 MPa, and HRA 34.1, respectively. The fracture surface indicated that the fracture of the material belonged to ductile rapture.

Similar content being viewed by others

References

Pietzka M.A. and Schuster J.C., Phase equilibria of the quaternary system Ti-Al-Sn-N at 900°C, J. Alloys Compd., 1997, 247(1–2): 198.

Bao Y.W., Wang X.H., Zhang H.B., and Zhou Y.C., Thermal shock behavior of Ti3AlC2 from between 200°C and 1300°C, J. Eur. Ceram. Soc., 2005, 25(14): 3367.

Tzenov N., Barsoum M.W., and El-Raghy T., Influence of small amounts of Fe and V on the synthesis and stability of Ti3SiC2, J. Eur. Ceram. Soc., 2000, 20(6): 801.

Guang H.L., Chen K.X., Zhou H.P., Guo J.M., and Ren K.G., Layered growth of Ti2AlC and Ti3AlC2 in combustion synthesis, Mater. Lett., 2007, 61(3): 779.

Yeh C.L. and Shen Y.G., Combustion synthesis of Ti3AlC2 from Ti/Al/C/TiC powder compacts, J. Alloys Compd., 2008, 466(1–2): 308.

Peng C.Q., Chang A.W., Yang S., and Huang Y., A novel simple method to stably synthesize Ti3AlC2 powder with high purity, Mater. Sci. Eng. A, 2006, 428(1–2): 54.

Zou Y., Sun Z.M., Hashimoto H., and Tada S., Low temperature synthesis of single-phase Ti3AlC2 through reactive sintering Ti/Al/C powders, Mater. Sci. Eng. A, 2008, 473(1–2): 90.

Zou Y., Sun Z.M., Hashimoto H., and Tada S., Synthesis reactions for Ti3AlC2 through pulse discharge sintering TiH2/Al/C powder mixture, J. Alloys Compd., 2009, 468(1–2): 217.

Li S.B., Xiang W.H., Zhai H.X., and Zhou Y., The kinetics of composite particle formation during mechanical alloying, J. Am. Ceram. Soc., 2005, 88(8): 2092.

Peng L.M., Fabrication and properties of Ti3AlC2 particulates reinforced copper composites, Scripta Mater., 2007, 56(9): 729.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, S., Kang, Q., Liu, J. et al. Fabrication of Ti3AlC2 ceramic material by mechanical alloying. Rare Metals 29, 376–379 (2010). https://doi.org/10.1007/s12598-010-0133-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-010-0133-0