Abstract

This paper uses a directional distance function and a single truncated bootstrap approach to investigate inefficiency of lowland farming systems in the Benin Republic. First, we employed a dual approach to estimate and decompose short-run profit inefficiency of each farming system into pure technical, allocative and scale inefficiency and also into input and output inefficiency. Second, an econometric analysis of factors affecting the inefficiency was generated using a single truncated bootstrap procedure to improve inefficiency analysis statistically and obtain consistent estimates. In the short run, scale, allocative and output inefficiency were found to be the main sources of inefficiency. Based on inefficiency results, the inefficiency of lowland farming systems is the most diverse. Compared to a vegetable farming system, technical inefficiency is significantly higher if farmers switch to a rice farming system. Scale, allocative, output, and input inefficiency are significantly lower with an integrated rice-vegetable farming system and there was high prevalence of increasing returns to scale in the integrated rice-vegetable farming system. Water control and lowland farming systems are complements and play a significant role in the level of inefficiency. Input inefficiency shows the difficulty that the producers face in adjusting the quality and quantity of seeds and fertilizers. The paper provides empirical support for efforts to promote an integrated rice-vegetable farming system in West Africa lowlands to increase food security.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As a result of trade liberalization, the agricultural sector of developing countries is increasingly influenced by developments in world markets. The perceived rate of food crises in those regions has increased sharply during this last decade. Moreover, recent studies found that the world commodity price boom that started several months ago has accentuated concerns about the potential severity of future crises in Southern Africa (Tschirley and Jayne 2008). Productivity performance in the agricultural sector is thus critical to improvement in overall economic well-being and can offer good opportunities for food security and poverty reduction. One of the major concerns relates to greater and more effective utilization of lowlands for agricultural production in Sub Saharan African regions (Gockowski and Ndoumbe 2004; Erenstein 2006; Erenstein et al. 2006; Weinberger and Lumpkin 2007; Barrett et al. 2008).

In Benin, due to the promotion of small scale agricultural lowland use since 1980, intensification and diversification practices are frequently observed in lowlands. Intensification is related to water control management where upstream pond and irrigation canals or canals to prevent flooding are built. Agriculture in the lowlands takes place on small peasant farms that produce annual food crops for subsistence and markets. Rice and vegetables are the first and second most important food crops produced. Improving economic efficiency of these crop based systems will contribute to improving overall agricultural productivity of this land with high agricultural potential. In addition, empirical evidence suggests that small farms are desirable not only because they reduce unemployment, but also because they provide a more equitable distribution of income as well as an effective demand structure for other sectors of the economy i.e. food security (Binam et al. 2004; Bravo-Ureta and Pinheiro 1993, 1997). Lowland cultivation in Benin comprises three major farming systems. The first is the integrated Rice-Vegetable farming system (RVFS). On the same plot, rice is produced during the rainy season while vegetables are cultivated in the dry season. The second is the Rice farming system (RFS) where rice is cultivated solely in the rainy season (May to November). The third is the Vegetable farming system (VFS) in which vegetables are produced on the plot exclusively in the dry season (December to April). Jute leaves (Corchorus olitorus), okra (Abelmoschus spp.) and amaranth (Amaranthus spp.) are the main vegetables produced in the central lowlands. Despite the enormous potential of Benin, only about 4% of the 205,000 ha available lowlands are cultivated. Several authors (Agli 2000; Verlinden and Soule 2003; Adégbola and Singbo 2003) found that in order to reduce the gap between domestic rice and vegetable consumption and supply for food security, the local production of rice needs to be increased by approximately 50,000 tons per year, and vegetable production by approximately 80,000 tons per year.

Traditionally, much of the interest in lowlands in West Africa has nevertheless focused on the potential for technologically-intensive rice production. Consequently, most farm level productivity growth and efficiency analysis has focused on rice production (Adesina and Djato 1997; Audibert 1997; Abdulai and Huffman 2002; Sherlund et al. 2002; Barrett et al. 2008). A major limitation of these studies is that a mono-cropping rice production is considered to be independent of its production system. In reality, the integrated rice-vegetable farming systems are technically highly interdependent (Erenstein et al. 2006). Thus, ignoring the farming system level in empirical studies may bias estimates of the efficiency analysis of a decision making unit (DMU) in lowlands. Focus on farming system level is in line with the grouping method developed by Farrell and Fieldhouse (1962) which permits the creation of homogeneous output groups.

Ever since Charnes et al. (1978) first estimated a regression to explain variation in the distribution of inefficiency of a DMU, there has been a continuing search for alternative specifications and functional forms. Both parametric and non parametric approaches to measuring inefficiency in the agricultural sector have evolved. However, parametric approaches are generally restricted by the functional specification underlying the production technology. Nonparametric approaches to measuring inefficiency are more flexible than parametric approaches, as they do not require a functional form to be specified for the production frontier. A well-known disadvantage of nonparametric approaches, however, are their deterministic nature, which implies that stochastic conditions, e.g., weather, may confound with inefficiency. Several studies that analyzed data with both non-parametric and parametric frontier estimators, however, did not show radical differences in the results with the various procedures (see Greene 2008 for details). In sum, by comparing non-parametric and parametric approaches, some authors finally indicated that in most empirical studies the selection of the methodology used to measure inefficiency is arbitrary and mainly based on the objective of the study, the data available and the personal preference of the researcher (Wadud and White 2000; Resti 2000).

A two-stage approach has become standard when Data Envelopment Analysis (DEA) is used to assess the inefficiency of decision making units (DMUs) and when there are factors not under control of the DMU that influence their performance. However, a standard two-stage approach used where inefficiency is estimated in the first-stage, and then the estimated inefficiencies are regressed on a group of explanatory variables of interest, gives rise to problems. First, the two-stage estimates can suffer from the independence condition between input variables used in the first stage and explanatory variables (Wilson 2003). Second, a serious problem in this standard two-stage approach arises from the fact that DEA inefficiency estimates are serially correlated. An alternative approach that does not suffer from these drawbacks was recently proposed by Simar and Wilson (2007), who developed single and double bootstrap procedures. These latter approaches also allow the second-stage regression to be estimated and inferences to be made using truncated regression.

The purpose of this paper is to estimate short run inefficiency, accounting for the farming system in lowlands based on the directional distance function, and to derive implications helpful in designing appropriate policies to promote optimal use of such lands. We employed the new two-stage inefficiency procedure to examine the potential production economic effects of lowland farming systems. Our study is one of the first to use the directional distance function framework and a single truncated bootstrap approach in the context of the two-stage approach. A convenient property of the directional distance function is that, unlike the traditional radial distance function, it easily accommodates the primal (production efficiency) and dual model (allocative efficiency). This enables us to compute the overall profit inefficiency which is the most natural measure of performance that is based on a difference rather than a ratio. This profit inefficiency measure is also called the Nerlovian profit efficiency (see Färe and Grosskopf 2004). The ratio profit level is not an adequate measure to calculate profit inefficiency not only because these ratios can result in negative profit efficiency measures (that are hard to interpret) but also because these ratios do not have a dual interpretation in terms of the required adjustments in inputs and outputs to achieve the maximum profit target (Thanassoulis et al. 2008). This is also practical, as farms may earn zero profit, which poses problems in a ratio context. We decomposed the overall inefficiency into pure technical, allocative, and scale inefficiency as well as output and input inefficiency for farms at farming system level. In the short run, lowland production technology is subject to levels of quasi-fixed inputs (land, equipment, and family labor). Given that most farms can adjust variable inputs more quickly than they can adjust quasi-fixed inputs, the calculation of short run inefficiencies may be of more immediate value (Tauer 1993). The empirical analysis of this article is based on a farm survey in central Benin, where monthly data were collected on rice and vegetable production in different lowland farming systems.

The remainder of the paper unfolds as follows. Section “Two-stage semi-parametric and bootstrap models” develops the theoretical model of inefficiency analysis based on a semi-parametric frontier approach, and especially on inefficiency measures using a short-run directional distance function and truncated bootstrapping method in the two-stage approach to analyzing inefficiency. This is followed by a description of the data and variables in section “Data and variables”. Section “Results and discussion” presents the research findings and discussion. The paper ends with a conclusion.

Two-stage semi-parametric and bootstrap models

Semi-parametric model for analyzing inefficiency

Directional technology distance function theory framework

Since development of the efficiency method by Farrell (1957) and Farrell and Fieldhouse (1962), there has been a growing interest in methodologies and their applications to efficiency measurement.

Using dual approaches, Chambers et al. (1996 and 1998) introduced directional distance functions as additive alternatives to the distance functions concepts. The directional distance function measures the amount that one can translate an input and or output vector non-radially from itself to the technology frontier in a preassigned direction (Chambers et al. 1998; Färe and Grosskopf 2000; Ray 2004). Hence, the Farrell decompositions of overall cost and revenue efficiency into allocative and technical efficiency are shown to be special cases of the corresponding profit efficiency decomposition. The directional distance function provides a measure of technical inefficiency; allocative inefficiency measures the residual inefficiency due to failure to choose the profit maximizing input–output bundle given prices. The directional distance function is shown to be appropriate in measuring lowland producer inefficiency for several reasons.

In central Benin, lowland cultivation is practiced in a delimited area of land, contrary to upland systems, where households can increase their farm size. Family labor is the principal source of labor used indicating that family labor is one of the main constraints for lowland cultivation. Moreover, lowland producers face exogenously determined input and output prices and attempt to allocate inputs and outputs so as to maximize profit. Under this behavior both inputs and outputs are determined endogenously. In other words, producers have to decide not only how much of various inputs to use, but also how much rice and/or vegetables to produce. On the other hand, Kumbhakar and Lovell (2000) suggest that if one is interested in estimating profit inefficiency in a price-taking environment, then it is appropriate to conduct the analysis within a short-run framework in which some inputs are exogenously determined because inefficient producers cannot survive in a long-run. In this context, the appropriate standard against which to evaluate profit inefficiency is the variable profit frontier. Following this assumption, producers are expected to maximize short term profit from their lowland farming systems. Thus, the directional distance functions we analyze are derived from the shortage function which generalizes the profit function in the short-run (Chambers et al. 1998; Färe and Grosskopf 2004). This approach determines the minimum combination of variable inputs such that the profit is at least as great as the profit obtained by the k th farm, and the quasi-fixed inputs used are no greater than the k th farm.

The reason for treating any inputs as quasi-fixed inputs in the short-run is to acknowledge the possibility that the first-order conditions for profit maximization are not satisfied for those inputs because of costs of adjustment. This setting is also consistent with our analysis because of the course of a single growing agricultural production year.

Assume that the directional distance function gives an appropriate representation of the production technology of a number of different lowland farming systems. Suppose that, for the j th farming system, there are sample data on n j farms that produce \( {y_{(j)}} \in \Re_{+}^M \) vector of outputs from \( {x_{(j)}} \in \Re_{+}^N \) vector of inputs which is decomposed as \( {x_v}_{(j)} \in \Re_{+}^N \) vectors of variable inputs and \( {x_f}_{(j)} \in \Re_{+}^N \) vector of quasi-fixed inputs. This farming system technology T j is given by:

We assume that the farming system technology is closed, variables inputs \( \left( {{x_{{v_{(j)}}}}} \right) \) and outputs are freely disposable, there is no free lunch, doing nothing is feasible and convex (Färe 1988; Färe and Grosskopf 2000). The short-run directional technology distance function is defined as:

if

where \( \left( {{g_{{x_v}_{(j)}}},{g_{{y_{(j)}}}}} \right) \) is a non zero vector in \( \Re_{+}^N \times \Re_{+}^M \) and determines the direction in which \( {\overrightarrow D_{{T_{(j)}}}}\left( . \right) \) is defined. Clearly, the interpretation of the inefficiency term depends on the choice of the directional vector. This short-run directional technology distance is defined as how much output can be expanded and variable input contracted and still be feasible in the short-run (see Fig. 1). \( {\overrightarrow D_{{T_{(j)}}}}\left( . \right) \) provides a direct measure of how far \( \left( {{x_v}_{(j)},{y_{(j)}}} \right) \) must be projected along \( \left( {{g_{{x_v}_{(j)}}},{g_{{y_{(j)}}}}} \right) \) to reach the frontier of T (j).

Profit inefficiency measures the normalized difference between maximum and observed profit. This allows an additive decomposition of profit inefficiency for each producer in each lowland farming system. For simplicity of presentation, after omitting the index j, the short-run overall profit inefficiency is defined as (Chambers et al. 1998):

where \( \pi \left( {p,w} \right) \) is the short run maximal profit, \( p \in \Re_{ + + }^M \) denote a vector of output prices and \( w \in \Re_{ + + }^N \) a vector of variable inputs prices. Since \( \pi \left( {p,w} \right) \) is by definition greater than or equal to observed profit, it follows that overall profit scores are greater than or equal to zero.

The profit function and the directional distance function provide the basis for defining and decomposing profit efficiency where we have a price (dual) and a quantity (primal) measure of inefficiency (Chambers et al. 1998; Färe and Grosskopf 2000; Ray 2004; Färe and Grosskopf 2004).

The overall profit inefficiency (OIE) is defined as the difference between the maximum profit and observed profit, normalized by the value of the reference variable inputs and output combination \( \left( {p{g_y} + w{g_{{x_v}}}} \right) \) which implies that zero profit poses no computational problems (Eq. 4). This inefficiency measurement also has the desirable property of being homogenous of degree zero in prices in the sense that it is independent of the measurement units.

In each lowland farming system, farm k is overall efficient if \( OIE\left( {p,w,y,{x_v};{g_{{x_v}}},{g_y}} \right)\left| {_{{x_f}}} \right. = 0 \) indicating that this specific farm achieves maximum profit.

Directional distance function computational procedure

The measure of short run technical inefficiency relative to a constant returns to scale (C, S) technology for each producer by farming system is obtained by solving several linear mathematical programming problems. Suppose a case of data for one farming system. Consider that, for each farming system, there are k = 1,...,K observations of inputs (variable and quasi-fixed) and outputs \( \left( {{x^k},{y^k}} \right) \). First, the short-run directional distance function used to describe the technical inefficiency in a particular farming system for observation k′ is defined by:

where the z k are the intensity variables, v denotes the variable input factors (operating costs. i.e. seeds and fertilizers) and where f = 1,2,3 are the fixed factors (labor, capital cost, and plot size).Footnote 1 The technology sets (5) also allows for variable returns to scale (V, S) due to the convexity constraints in order to compute pure technical inefficiency (PTIE); then \( {\overrightarrow D_{TE}}\left( {x_f^{k{\prime}},{y^{k{\prime}}}; - x,y\left| {V,S} \right.} \right) \) is computed as in (5) by adding the \( \sum\limits_{k = 1}^K {{z_k} = 1} \). That is, variable returns to scale allows the lowland farming technology to exhibit increasing, constant or decreasing returns to scale. The convexity restriction \( \sum\limits_{k = 1}^K {{z_k} \leqslant 1} \) in \( {\overrightarrow D_{TE}}\left( {x_f^{k{\prime}},{y^{k{\prime}}}; - x,y\left| {NI,S} \right.} \right) \) and \( \sum\limits_{k = 1}^K {{z_k} \geqslant 1} \) in \( {\overrightarrow D_{TE}}\left( {x_f^{k{\prime}},{y^{k{\prime}}}; - x,y\left| {ND,S} \right.} \right) \) display nonincreasing and nondecreasing returns, respectively. Consequently, this convexity constraint allows for the possibility of negative, positive or zero profit (Fukuyama 2003).

Second, to compute the profit decomposition, we compute maximal profit for each producer relative to the technology T by solving the following linear programming problem for observation k′ for each farm in each farming system:

where the λ k are the intensity variables, and all the other variables are the same as defined in (5). The short run maximum profit model (6) assumes variable returns to scale (VRS) as, for a technology exhibiting globally constant returns to scale (CRS), either the maximum profit level is zero or the solution of the maximum profit model is undefined (Thanassoulis et al. 2008). Profit maximization in relation to a VRS technology implies that perfectly competitive markets are not assumed, since under this assumption all farms have zero profits in the long run.

As mentioned above, maximal profit π(p, w) minus observed profit \( \left( {py - w{x_v}} \right) \), normalized by \( \left( {p{g_y} + w{g_{{x_v}}}} \right) = \left( {py + w{x_v}} \right) \), yields overall profit inefficiency (OIE). Since overall profit inefficiency (OIE) consists also of pure technical inefficiency (PTIE), allocative inefficiency (AIE) and scale inefficiency (SIE) such that OIE = PTIE + AIE + SIE, the next step is to compute short-run allocative inefficiency for each observation in each farming system by subtracting its short-run overall inefficiency from its short-run pure technical and scale inefficiency. In our DEA modeling approach, the allocative inefficiency also incorporates inefficiency due to slacks.

Since overall profit inefficiency (OIE) also consists of input inefficiency (INIE) and output inefficiency (REVI) such that OIE = REVI + INIE, the third step is to compute short-run input and output inefficiency.

Second-stage analysis: truncated bootstrap model

The conventional two-stage approach used censored regression and has been widely applied to determine whether or not certain factors influence the decision making unit’s (DMU’s) inefficiency scores (see Fried et al. 2002; Gattoufi et al. 2004 for a comprehensive bibliography). This traditional censored regression procedure, however, is invalid because of the presence of the inherent dependence among the DEA efficiency scores which are a relative efficiency index instead of an absolute efficiency index. This suggests the violation of one of the basic model assumptions required by regression analysis. Authors found that a more serious problem in these methods arises from the fact that non parametric efficiency estimates are serially correlated in a complex way. Simar and Wilson (2007) found that it is difficult to give a statistical interpretation to the second stage estimator and also not provided a coherent description of a Data Generating Process (DGP). To overcome the problem of complex serial correlation in analysis of the DEA efficiency scores, Xue and Harker (1999) used a naïve bootstrap approach to address different problems in regression analysis (e.g. the non-normality of the distribution). The bootstrap is a method for estimating the distribution of an estimator or test statistic by resampling the data or a model estimated from the data (bootstrap sampling). Therefore, the bootstrap is a practical procedure for reducing errors in inference (Horowitz 2001). The main idea of the naïve bootstrap approach is to substitute the incorrect conventional estimators for the standard errors of the regression coefficient estimates with bootstrap estimators for the standard errors of these estimates. A naïve bootstrap method requires only the randomness of the observed sample. In Xue and Harker (1999), this requires the independence among the DMUs in terms of their inputs, outputs, and the explanatory variables but not the independence of their DEA efficiency scores. Recently, Simar and Wilson (2007) demonstrated that this naïve bootstrap approach is inconsistent in the context of non-parametric efficiency estimation and it is unclear what is being estimated. To rationalize the two-stage analysis, they proposed single and double bootstrap procedures which allow not only for heterogeneity in the distribution of inefficiency, but also incorporate assumptions on separability between the production set and the covariates. Given the small size of the sample and the number of variables considered in this study, a single truncated bootstrap is used. This single truncated bootstrap is an application of the Simar and Wilson (2007) method for radial distance functions to the case of the directional distance function.Footnote 2

Data and variables

This study was conducted in the Dassa local government area of Collines Department, Benin. The town of Dassa (2°02 N, 2°20 W) is located in central Benin, 250 km north of the economic capital Cotonou and close to the nationally and regionally important agricultural market Glazoue. The road from Dassa to Cotonou is paved, and many heavy trucks transport agricultural goods from Collines Department to Cotonou. The region has the highest concentration of lowlands in Benin, and receives a lot of support from different projects and research organizations. For instance, since 2000 the Africa Rice Centre (WARDA) increased lowland activities in this region through their national lowlands consortium. This suggests that the area has good market access and high agricultural potential. A farm-level survey was conducted during the agricultural seasons of 2004 and 2005 to provide demographic data. The data set consisted of a stratified random sample survey of 72 producers in three villages (Odo Otchere, Ouissi and Gankpetin) where lowlands are cultivated, and the study followed their activities on 93 plots. It is worth noting that the number of producers in this sample represents more than 60% of lowland producers registered in that region. To avoid heterogeneity problems at farm level analysis in cross-selection data, lowland farming system is used as stratification criterion for sampling farms. The sampling unit was the plot. Some producers had more than one plot. The 93 plots were classified into 30 plots for the integrated rice-vegetable farming system (RVFS), 28 plots for the rice farming system (RFS) and 35 plots for the vegetable farming system (VFS).

Questionnaires were used to collect data on producers’ input and output use as well as socio-economic and environmental factors. To reduce the occurrence of measurement errors in the cross-section data, the questionnaire was improved following the pre-test. Data collection took place on a monthly basis from June 2004 to June 2005. Collecting data on a monthly basis enabled this study to capture the detailed cost and the revenue of production (measuring the quantities of inputs used, the prices at farm gate, labor used, measuring the output quantities obtained). Questionnaire design and data collection work were carried out under the supervision of the first author.

First stage data

The first stage data consisted of two outputs and three types of inputs. Outputs are rice and/or vegetables. The most important inputs in lowland cultivation are operating costs, labor and small materials (hoes, axes, machetes, watering cans, baskets, basins, etc.). Cultivation practices include land clearing, soil tillage, construction of beds, fertilization, planting, irrigation, weeding, and harvesting. Variables collected from the farmer survey were revenues from lowland crops (rice, and vegetables), expenses (seeds, labor, fertilizers, equipment, etc.). As rice is produced from May to November, inputs used to produce rice in this period were aggregated. Vegetables are cultivated in lowland from December to April. Inputs and outputs for vegetables were also aggregated for this period. Output consisted of rice or vegetables produced in each farming period.

The inputs and the outputs we specify are based upon the production process of lowland farms. We had to address the trade off between using technical details by applying more inputs and adding the risk of multicollinearity on the one hand, and aggregating the inputs and sacrificing potentially useful information on the other hand. To avoid the risk of multicollinearity and the ‘zero-observation’ problem for input variables in the first stage, the inputs were aggregated into three categories (labor costs, operating costs, and capital), and the outputs were aggregated into a single index of lowland farm output. The linear aggregator was used to aggregate inputs and outputs. The input and output prices obtained did not vary across farms, implying that differences in the composition of a netput on the quality were reflected in the quantity (Cox and Wohlgenant 1986). Thus, to implement the overall profit inefficiency given by (6) we assumed that all farms face the same output-input prices vector (i.e. unity).

Labor input consisted of family labor and paid labor, measured at their effective costs. A problem was that reported hours of work may have had errors. The opportunity cost of family labor is determined within the household rather than by market forces and consists of expenditures for food to sustain family labor of the farm operator capturing cross-sectional price variation. In Benin rural area, the labor market is constrained; especially women have a limited set of alternatives to remunerate their labor. In addition, neither hired and family labor nor the labor inputs of different family members are perfectly substitutable in agricultural production (Jacoby 1993). As family and hired labor are not perfect substitutes, the labor supply model could be used to estimate the household’s unobserved shadow wage (Barrett et al. 2008; Barrett 1997). However, the objective of this paper was not to estimate structural labor supply in order to determine the shadow wages allocative inefficiency; the direct realized labor prices were used rather than the subjective, ex ante expected prices as proposed by Barrett (1997). It is also important to remember that our inefficiency method is homogeneous of degree zero in prices. As labor input was treated as quasi-fixed in our model, the choice was consistent so that allocative and scale inefficiency were related to operating inputs. Labor was assumed to be a quasi fixed input because a large share of total labor consisted of family labor. The family labor represented about 80% to 90% of the total labor used in the Beninese lowlands (measured in man-days). The capital cost was computed as the sum of the real annual costs of materials involved in the production system.Footnote 3 The operating costs were computed as the sum of seed and mineral costs. The output value denotes the value of output involved in the given farming system evaluated at their farm-gate prices. In the directional distance function, we need to choose a directional vector, \( \left( {{g_{{x_v}}},{g_y}} \right) \), common to all farms in each farming system to aggregate the measures’ technical inefficiency. Following Färe and Grosskopf (2004), in a given lowland farming system, if each farm’s technology is such that the maximal profit function yields optimal outputs and optimal inputs which are the same for all farms, then a natural direction yielding for \( k = 1,...,K \) farms is \( \left( {x_v^*,{y^*}} \right) \). Unfortunately, in each farming system the optimal outputs and optimal inputs varied for each farm. Therefore, we measured technical inefficiency in the direction of the realized variable inputs-output vector \( \left( {{x_v},y} \right) \) (Chambers et al. 1998): in this case \( \left( {p{g_y} + w{g_{{x_v}}}} \right) = py + w{x_v} \). This directional vector implies that the directional technology distance function gives an estimate of the maximum feasible expansion in outputs and the contraction in variable inputs. Thus, it is possible to make a radial interpretation of our inefficiency measures.

Descriptive statistics of variables for different lowland farming systems is presented in Table 1. These statistics indicate that there were considerable differences within and among the three farming systems in terms of the means and standard deviations of the outputs and inputs.

Second stage data

The second stage involves an explanatory analysis of the inefficiency scores using environmental and farmers’ characteristic variables to account for exogenous factors that affect the inefficiency performance of producers. This explanatory analysis assumes that the environmental and farmers’ socio-economic variables only affect the inefficiency and not the transformation process of inputs into outputs. Possible factors influencing lowland inefficiency include environmental factors (water control), farming system (integrated rice and vegetables), as well as producers’ characteristics. Variables collected from the farmer survey were farm characteristics (upland farm size, number of family members, marital status, level of education, age, years of management experience in the lowland, etc.) and environmental factors (type of lowlands). The following variables were assumed to explain the variation of pure technical, allocative and scale inefficiency scores:

-

Number of family members available for lowland farm work in adult workforce (NHADULT). Lowland cultivation is often considered more onerous and labor demanding than upland cultivation (Spencer and Byerlee 1976; Richards 1986). In addition, rice production coincides with the rainy season. Therefore, farmers with limited family labor are less likely to produce rice, as they would have to hire labor for rice production, reducing expected profits. Also, the production of vegetables has higher labor requirements than the production of staple crops or grains. Weinberger and Lumpkin (2007) found that vegetable production required twice as much, sometimes up to four times as much labor as the production of cereal crops. Therefore, a negative relationship was expected between technical or scale inefficiency scores and availability of family labor. On the other hand, family labor in rural areas is assumed to be less productive because this type of labor has low opportunity costs (Gockowski and Ndoumbe 2004). Thus, this variable was expected to increase allocative inefficiency.

-

Formal Education of the farmer (EDUC). Various types of training help the farm operator to enhance profitability. Farmers who received a formal education are more likely to have been exposed to information on lowland cultivation technologies. Furthermore, educated farmers are expected to have better capabilities in processing information and searching for appropriate technologies to reduce use of inputs. Education of the farmer is expected to reduce technical inefficiency or what Welch has called ‘worker effect’ (Welch 1970; Sidhu and Baanante 1979). However, Huffman (1974) reported that the contribution of education is only an ‘allocative effect’. Stefanou and Saxena (1988) found that education may enhance the farmer’s ability to allocate inputs efficiently across competing uses, and contribute to good farm planning. Therefore, it was assumed in this study that the variable EDUC had a negative effect on technical, allocative and scale inefficiency.

-

Age of farmers (AGE). The age of producers captures differences in the quality of management. Age provides a major source of possible variation of inefficiency across producers since older farmers may lack up to date technology, machinery, equipment or structures. Richards (1986) argued that participating in brushing and ploughing in lowlands made clear that the most strenuous tasks are placed on young people. Old farmers are less likely to conduct lowland activities. In contrast, young women tend to work very hard in the lowlands. Therefore, the age of farmers was assumed to have a positive effect on inefficiency scores. Hence, the variable AGE was assumed to increase technical inefficiency in lowland farming systems; the effect was less clear for allocative and scale inefficiency.

-

Marital status (MARRIED). The effect of marital status on the level of inefficiency is difficult to predict. The lowland producers in the sample mainly consisted of women (85%). Married women are known to be responsible for many activities (cooking, fetching and carrying water, etc.) which decrease their performance in the agricultural sector (Gockowski and Ndoumbe 2004). In contrast, older married women tend to have more family labor at their disposal, which is expected to decrease technical inefficiency of lowland cultivation (Richards 1986). Thus, this variable could have either a positive or a negative effect on farmers’ inefficiency.

-

Irrigated lowland (TYBAS). Water control in lowlands has a particular importance in increasing agricultural production and productivity and facilitates intensification. It enhances weed control, improves N fertilizer use efficiency in rice and makes cultivation less risky (Becker and Johnson 1999 and 2001). Lack of water control can be an important constraint to lowland intensification (Erenstein 2006). This variable also measures the physical environment of the farm. It is therefore expected that irrigation may decrease technical, allocative and scale inefficiency scores. To be consistent with the separable condition between environmental factors and inefficiency estimates, water control was coded as a dummy variable.

-

Years of management experience in lowland (YEAR). This variable is related to the lowland management quality and can also be seen as an informal training ‘learning by doing’. As the results of experimenting with alternative production techniques, the management experience can lead to gains in efficiency through better organization and knowledge (Stefanou and Saxena 1988). Therefore, it was assumed that a decrease in lowland farming systems inefficiencies may result from more management experience.

-

Upland farm size (UPLAND). At farm system level, lowland and upland cultivation are complementary, but during the rainy season, lowland cultivation often comes second to upland cultivation due to the generally stricter timeliness, larger crop areas, increased diversity through preference heterogeneity and lower labor intensity of upland cultivation (Richards 1986; Lavigne-Delville and Boucher 1998). Consequently, there may be limited interest in lowland intensification for farmers who hold large upland areas. Therefore, this variable was expected to increase technical inefficiency scores and scale inefficiency as well. But, a farmer who owns a large area of upland was expected to decrease allocative inefficiency because of the higher opportunity cost of the inputs used.

-

To test whether the inefficiency of the three farming systems differs, we created two indicator (dummy) variables: RVFS (integrated rice-vegetable farming system) and RFS (rice farming system). We compared these variables to the reference system (VFS). Compared to vegetable farming systems, integrated rice-vegetable farming systems and rice farming systems were expected to be more technical, allocative and scale efficient.

The dataset shows that 21 producers engaged simultaneously in two farming systems (RFS and VFS). However, the correlation matrix of the explanatory variables showed that none of the Pearson partial correlation coefficients was high, indicating that there were no multicollinearity problems (see Annex).

Also, we assumed that the effects of the variable TYBAS and the farming systems were dependent and strictly multiplicative, so that the joint effect was the product of the marginal effects. This implies that we allowed for interaction effects in evaluating these qualitative factors. Then, we created two variables: TYBAS*RVFS and TYBAS*RFS.

Results and discussion

Inefficiency results

A profit function and directional distance function was estimated using GAMS (General Algebraic Modeling System). The measures of short-run overall profit inefficiency, pure technical, allocative, and scale inefficiency as well as input and output inefficiencies for individual decision making units in each lowland farming system were calculated and summarized in Table 2. The last column shows the directional technology scale inefficiency status identified with the use of the Fukuyama (2003) description. Recall that values of the overall, pure technical and allocative inefficiency scores equal to zero signify efficiency and values of the scores greater than zero signify inefficiency. Integrated rice-vegetables farming system (RVFS) had one third farmers (11 out of the 30 RFVS) who operated at the frontier of overall efficient (OIE = 0) and rice farming system (RFS) had 13 out of the 28 farmers fully efficient; vegetable farming system (VFS) had only 3 out of the 35 farmers who were efficient. Although for a few lowland farmers in each farming system, pure technical inefficiency was an important source of inefficiency, for most lowland producers allocative inefficiency and scale inefficiency were the major components for overall inefficiency. The results indicate that variable resource (seeds and minerals) allocation decisions particularly lacked profit maximizing behavior. Only 4 out of the 30 producers of RVFS, 7 out of the 28 of RFS, and only 2 out of the 35 of VFS were fully allocatively efficient in the short run (AIE = 0). This implies that 87% of producers in RVFS, 75% in RFS, and 94% in VFS were allocatively inefficient.

The arithmetic mean value of pure technical inefficiency (PTIE) measure in the short run at the farming system level ranged from 0.169 for VFS to 0.349 for RFS, indicating that gains from improving pure technical inefficiency existed. For example, average farms in Rice farming system (RFS) could expand rice output by 34.9% and contract seed and fertilizers use by 34.9% while farms in Vegetable farming system (VFS) could expand vegetable output by 16.9% and contract seeds and fertilizers by 16.98%. Eleven producers in RVFS, two in RFS and nine in VFS produced the maximum output possible, indicating that the majority of producers encountered problems which could include technical production constraints and socioeconomic and/or environmental factors. The results of this study imply that many of the lowland farms operate at technical inefficiency levels well below the efficient frontier. The inefficiency levels observed suggest a substantial amount of variable input savings and output expansions. If the average farmer in each group of the sample could eliminate pure technically inefficiency then he could realize a gain of 20% of the sum of revenue and variable cost in RVFS, 35% in RFS, and 17% in VFS. This result suggests that the majority of lowlands producers may have a substantial gain from improving efficiency of variable resource use.

The overall profit inefficiency equals the normalized difference between maximal and actual profits. The mean of overall profit inefficiency (OIE) ranged from 0.085 for RFS to 0.401 for RVFS indicating greater profit inefficiency in lowland farming systems. The residual difference between overall inefficiency and technical inefficiency is allocative inefficiency. In the short run, farmers in VFS appeared to be more allocatively inefficient: mean allocative inefficient measures were 0.006 in RFS, 0.030 in RVFS, and 0.117 in VFS. This result is in line with the finding of Erenstein (2006) that lowlands are not always as valuable as they may seem, and there may be limited incentives to intensify.

On average, farmers of integrated rice-vegetable farming system (RVFS) were found to be more scale inefficient than they were allocatively inefficient. This implies that there was a scale effect on the overall inefficiency of RVFS. By contrast, farmers in RFS and VFS appeared to be less scale inefficient than they were allocatively inefficient. Mean scale inefficiency ranged from 0.171 in RVFS to 0.224 in RFS. Within the sample, only 13.33% farms in RVFS, 17.14% farms in VFS and 3.57% farms in RFS were scale efficient (i.e. operating at constant returns to scale: SIE = 0). Thus, most of the farms in the sample were scale inefficient and this type of inefficiency appears to be as serious a problem as overall inefficiency. Scale inefficiency indicates that lowland farms do not have the optimal size. The study further reveals scale inefficiency among farming systems and shows that the range of optimal scale is extremely wide, with both the maximal and minimal outputs as the optimal scale. Increasing returns to scale was the predominant form of scale inefficiency observed in RVFS while decreasing returns to scale was the predominant form in RFS. Furthermore, both increasing returns and decreasing returns to scale were the prevalent scale inefficiency in VFS. Approximately four–fifth of the farms in RVFS (83.33%) against one-half of the farms in VFS (48.57%) and no farm in RFS were found to operate at increasing returns to scale. By contrast, 3.33% of the farms in RVFS, against approximately one-third of the farms in VFS (34.29%) and 96.43% of the farms in RFS were operating at decreasing returns to scale. The farms with increasing returns to scale should consider increasing their size and those with decreasing returns to scale should consider reducing their size. On average, farmers in RVFS had a positive directional technology scale elasticity value of 0.171 and hence displayed increasing returns to scale. The high prevalence of increasing returns to scale in RVFS implies that farms which adopted the integrated system should increase their size indicating expansion of rice and vegetable outputs and simultaneously contraction of variable inputs to increase unit profit. However, the high presence of decreasing returns to scale in RFS indicates farmers who cultivated only rice should reduce their size. In RVFS, farms that were scale efficient had a variable farm profit that was 52% larger than that of the scale inefficient farms. Similarly, farms that were scale efficient in VFS had a variable farm profit that was 48% larger than that of the scale inefficient farms. In contrast, the unique farm that was scale efficient in RFS had a variable profit that was 41% smaller than that of the scale inefficient farms. The results confirmed that decreasing returns to scale is the predominant form of scale inefficiency observed in RFS.

Finally, in the short run, farmers appeared to be more output inefficient (REVI) than they were input inefficient (INIE). Output inefficiency was mainly due to low yields, implying that a major effort has to be undertaken to increase yield levels and/or postharvest facilities that help to conserve yield (Weinberger and Lumpkin 2007). The input inefficiency demonstrated that the observed variable inputs (seed and fertilizers) were not used at the optimal level showing that access to good quality seeds and fertilizers was a severe constraint for most farms (Cox and Wohlgenant 1986). This finding also implies that farmers face high (shadow) prices for cash inputs because of liquidity constraints. First, farmers were mostly using the same traditional seeds, or if they had ever used improved hybrid seeds, they propagated it themselves, and the productivity of the seed would have deteriorated over time as a result. Second, the NPK fertilizers available in Benin are recommended and commercialized especially for cotton. Input inefficiency was also caused by the difficulty that producers face in adjusting the quality and quantity of inputs. This is in line with the findings of Crawford et al. (2003) who found that the increase in fertilizer in Benin is largely attributable to the expansion of fertilizer use by the cotton sector. The authors categorized the causes of low input use (fertilizer and seed) in food crops as a function of weak incentives and capacity to purchase inputs. Following Kelly (2005), Crawford et al. (2003), and Jayne et al. (2003), successful increase in the use of fertilizer and seeds requires policies and programs that ensure economically sound and technically efficient use. The results suggest that lowland producers face managerial or organizational problems that inhibit them from adjusting the use of operating inputs.

To address the question why inefficiency is so pervasive in lowland farming in Benin, factors contributing to these inefficiency scores were further investigated.

Truncated bootstrap analysis of Sources of inefficiency

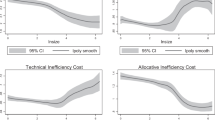

A single truncated bootstrap procedure explaining inefficiency as defined in section “Second-stage analysis: truncated bootstrap model” were estimated using Stata software version 9.0. The bootstrap was run using L = 2000 replications as suggested by Simar and Wilson (2007) by pooling data across all three farming systems. Table 3 shows second stage beta coefficients and Bootstrap Confidence Intervals for pure technical, allocative and scale inefficiency estimates. Positively related variables increase inefficiency while negatively related variables decrease inefficiency. A parameter estimate is significant when the value of zero is not within the confidence interval.

Technical inefficiency was significantly and negatively affected by TybasRVFS (joint effect of water control and integrated rice-vegetable farming system), TybasRFS (joint effect of water control and rice farming system), Married (married household), Educ (producers who have a formal education), Nhadult (number of family members available for lowland farm work), and Year (number of years of management experience in the lowland). On the other hand, technical inefficiency was significantly and positively affected by RFS (rice farming system), RVFS (integrated rice-vegetable farming system), Tybas (water control), and Age (farmer’s age). The significance of the effects of the two farming systems (RVFS and RFS) suggests in the short run, that the three lowland farming systems are different in terms of technical inefficiency. Their positive effects imply that rice farming system (RFS) and integrated rice-vegetable farming system (RVFS) ceteris paribus have a higher technical inefficiency than the vegetable farming system (VFS). This suggests that the degree of technical inefficiency of vegetable’s producers is less than that of rice farmers. The result indicates that despite the fact that much of the interest in lowlands in West Africa has focused on the potential for technologically-intensive rice production (Erenstein et al. 2006), rice production technology is still a severe constraint for farmers. The effect of water control (Tybas) was shown to have significant and positive effects on technical inefficiency, indicating that technical efficiency is not enhanced by only water control. The joint effect of water control and rice farming system (TybasRFS) and the joint effect of water control and integrated rice-vegetable farming system (TybasRVFS) were shown to have significant and negative effects on technical inefficiency, suggesting that water control and farming systems have a decreased interaction effect on technical inefficiency. Thus, the level of irrigation and lowland farming systems are complements and play a significant role in the level of inefficiency. Furthermore, the results indicate that formal education and additional years of management experience resulted in lower technical inefficiency. This implies that increasing investment in formal and informal education might lead to better performance in the agricultural sector (Dhungana et al. 2004) and that education and experience are substitutes and play a significant role in the level of technical inefficiency. The positive effect of producer age on technical inefficiency suggests that younger farmers are more likely to be technically efficient than their older counterparts. This is consistent with the findings of Dhungana et al. (2004) who showed that, in Nepalese rice farms, younger farmers may be more willing to adopt new technologies and/or to have a stronger educational background. The households that had a higher number of family members performed better in terms of technical efficiency. The hypothesis that a higher upland farm size significantly raises technical inefficiency in the lowlands was not confirmed. A plausible explanation is that higher upland farm size is interpreted by households as a strategy for risk diversification.

Results showed that allocative inefficiency was affected significantly and negatively by RFS (rice farming system), Tybas (water control), TybasRFS (joint effect of water control and rice farming system), Married, and Upland (upland farm size) and positively by the joint effect of water control and integrated rice-vegetable farming system (TybasRVFS), number of adult members available for lowland farm work (Nhadult), Educ (formal education) and Year (number of years of management experience in lowlands). Further, the results indicated that water control and farming system have a joint negative effect on allocative inefficiency. Producers dealing with the rice farming system on irrigated plots were more successful in choosing a mix of variable inputs that maximizes profit at given input prices than those who grow only vegetables on the same type of plot. However, the results also suggest that producers who farm in water control lowland succeed better in making profit efficient choices of variable inputs. Thus, the best irrigation scheme has a negative effect on allocative inefficiency. The hypothesis that educated farmers and lowland management experience have a negative effect on allocative inefficiency is rejected. This is not consistent with the finding of Stefanou and Saxena (1988) who found that operators of dairy farms in Pennsylvania with post-secondary education demonstrated a greater degree of flexibility in the allocation of variable inputs. The significant effect of the joint interaction of water control and lowland farming systems (TybasRFS and TybasRVFS) on allocative inefficiency indicates that the level of irrigation and lowland farming systems are complements and also play a significant role in allocative efficiency. This result corroborates the finding of Erenstein et al. (2006) that temporal integration of rice and vegetables is constrained by the limited degree of water control in West African lowlands.

Scale inefficiency was affected negatively and significantly by Tybas, Married, Educ, Nhadult, TybasRFS, and Year and positively by TybasRVFS, RFS, Upland, and Age. The insignificant coefficient of the RVFS indicates that the scale inefficiency effect of the integrated rice-vegetable farming system is similar to that of vegetable farming system. The results also suggest that water control and lowland farming systems are complements and play a significant role in scale inefficiency. Our results show that irrigated lowland and rice farming system have a negative joint interaction on scale inefficiency indicating that producers who cultivated only rice on irrigated plots operate on a more optimal (higher) scale than those who produced only vegetables on irrigated plots. This result demonstrates that the contribution of the policy of technologically-intensive rice production is a scale effect. The results also suggest that educated farmers and more years of management experience in lowland cultivation decrease scale inefficiency. The implication is that education and experience are substitutes and also play a significant role in the level of scale efficiency. The producer age and additional upland size increase scale inefficiency. It appears that farmers with relatively higher upland size are less scale efficient than the others. Also, young farmers tend to be more scale efficient than old farmers. Large number of family members available for lowland farming decreased scale inefficiency, implying that households with much family labor tend to operate at the optimal size.

The joint test of water control and farming systems interaction coefficients rejects the null hypothesis of independence of water control and farming systems. Because the interaction terms are jointly significant, it would be a misspecification to fit the regression based on independent and strictly additivity of the two factors.

The results in this paper are in line with previous findings (Erenstein 2006; and Erenstein et al. 2006) indicating that the degree of economic motivation and success in the allocation of resources in Benin’s lowlands differ significantly among farming systems. In the short run, producers were not able to allocate their resources optimally in the profit maximizing sense. Furthermore, technical, allocative, and scale inefficiencies differed significantly among farming systems. Researchers who have examined lowlands practices in West Africa believed that inefficiency could be improved through better management practices (Erenstein et al. 2006). Management practices do play an important role in production as shown by the parameter estimates for family labor, water control and upland farm size. In addition, a better policy should be implemented for seeds and fertilizers to increase outputs and reduce inputs used. The results of the three farming systems indicated that the profit loss due to technical inefficiency is quite similar across them. This implies that all producers have difficulty obtaining optimum input–output mixes, although vegetables producers were somewhat more technically efficient than the farmers of the other systems. A more likely explanation, as shown by the second stage result, may be the educational need to teach farmers the value and use of lowland technology (irrigation, inputs used in lowland, etc.). In the short run, basic farm management training could possibly address this problem. Allocative inefficiency increased with the variability of prices faced by producers in local markets implying that alternative strategies for reducing producers’ price volatility might be implemented. Finally, the results of this study are in line with the policy implication of the OECD (Organization for Economic Co-operation and Development) that agricultural production in developing countries can be enhanced through appropriate technology and management techniques applied to farms, resources and land. These will not harm the environment and will enable developing countries to reach the goal of food security. To reach this goal, lowland production processes could be reorganized and resources managed more effectively. Producers’ levels of education and farming skills should be upgraded and policy makers must search for incentives conducive to farmers’ adoption of appropriate technology (OECD 2008).

Conclusion

This paper aimed to examine differences in economic inefficiency among lowland producers at farming system level to assess a farm’s competitive position. It estimated several performance measures such as overall, technical, allocative, scale, input, and output inefficiency; moreover sources of inefficiency are analyzed. We employed a new robust two stage semi-parametric directional technology distance function approach and a single truncated bootstrap procedure to analyze the inefficiency performance of lowland farming systems.

The first stage results indicated that there was evidence of significant technical, allocative, and scale inefficiencies among producers of which scale inefficiency, allocative inefficiency and output inefficiency were the main sources of inefficiency. It is possible for the producers to increase profit gain of rice and vegetable production by removing these inefficiencies. Increasing returns to scale prevailed in the integrated rice-vegetable farming system. Input inefficiency indicated that variable inputs (seed and fertilizers) were not used at the optimal level, reflecting limited access to quality and quantity of seeds and fertilizers for most farms.

To address the issue of why inefficiency is so pervasive, the second stage results examined the influence of environmental and socio-economic factors on the inefficiency performance of the lowlands producers. There were substantial differences between the three lowland farming systems. Compared to the vegetable farming system, technical inefficiency increased significantly when farmers produced only rice in the rainy season. Allocative and scale inefficiency decreased more significantly with rice farming system or an integrated rice-vegetable farming system. Water control, size of family workforce, years of management experience in lowland cultivation, and the upland farm size held by the households were other factors influencing inefficiency of farmers in lowlands. Formal education and experience were substitutes whereas water control and lowland farming systems were complements, each having a significant effect on the level of inefficiency. Finally, there is economic and food security gain in promoting lowland development strategies with integrated rice-vegetable farming systems.

Notes

The directional distance function contracts variable inputs and expands output, at given levels of the three quasi-fixed inputs as demonstrated in Eq. 5. However, in order to make a correct representation of the production technology all inputs (variable and fixed) must be included in the model, where the fixed inputs are not corrected (see Eq. 5). If not, the estimates will suffer from omitted variable bias. The estimated profit function maximises the difference between revenues and variable costs at given levels of the three quasi-fixed inputs.

The application to the directional distance function follows the same reasoning as Simar and Wilson (2007). Details on the algorithm are available upon request from the authors.

The partial annual cost of each material was calculated as follow: the number of a given material really used in the plot multiplied by its purchase price at farm gate divided by the probable length of time that it will be used for (in one year). The real annual cost is then calculated by multiplying this partial annual cost by the proportion of time the involved material was used in a given production system or to produce a given crop.

References

Abdulai A, Huffman W (2002) Structural Adjustment and Economic Efficiency of Rice Farmers in Northern Ghana. Econ Dev Cult Change 48(3):503–520

Adégbola PY, Singbo AG (2003) Compétitivité de la filière riz du Bénin dans l’économie internationale, PAPA/INRAB, Porto-Novo. Communication de la 24ème session du Conseil des Ministres de l’ADRAO tenue du 17 au 19 septembre 2003, Cotonou. Pp 20

Adesina AA, Djato KK (1997) Relative efficiency of women as farm managers: Profit function analysis in Côte d'Ivoire. Agric Econ 16:47–53

Agli C (2000) Etude de la filière cultures-maraîchères dans les zones humides du sud-Bénin: circuits de commercialisation et faisabilité économique de la relance de la filière. Agence Béninoise pour l’environnement, Ministère de l’environnement, de l’habitat et de l’urbanisme, Bénin, pp 28

Audibert M (1997) Technical inefficiency effects among paddy farmers in the villages of the ‘Office du Niger’, Mali, West Africa. J Prod Anal 8:379–394

Barrett CB, Sherlund SM, Adesina AA (2008) Shadow wages, allocative inefficiency, and labor supply in smallholder agriculture. Agric Econ 38:21–34

Barrett CB (1997) How credible are estimates of peasant allocative, scale, or scope efficiency? A commentary. J Int Dev 9:221–229

Becker M, Johnson DE (1999) Rice yield and productivity gaps in irrigated systems of the forest zone of Côte d’Ivoire. Field Crops Res 60:201–208

Becker M, Johnson DE (2001) Improved water control and crop management effects on lowland rice productivity in West Africa. Nutr Cycl Agroecosyst 59:119–127

Binam NJ, Tonye J, Wandji N, Nyambi G, Akoa M (2004) Factors affecting the technical efficiency among smallholder farmers in the slash and burn agriculture zone of Cameroon. Food Policy 29:531–545

Bravo-Ureta BE, Pinheiro AE (1993) Efficiency analysis of developing country agriculture: a review of the frontier function literature. Agric Resour Econ Rev 22(1):88–101

Bravo-Ureta BE, Pinheiro AE (1997) Technical, economic and allocative efficiency in peasant farming: evidence from the Dominican Republic. The Developing Economics xxxv-1, 48–67

Chambers RG, Chung Y, Färe R (1996) Benefit and distance functions. J Econ Theory 70:407–419

Chambers RG, Chung Y, Färe R (1998) Profit, Directional Distance Functions, aand Nervolian Efficiency. J Optim Theory Appl 98(2):351–364

Charnes A, Cooper WW, Rhodes E (1978) Measuring the efficiency of decision-making units. Eur J Oper Res 2:429–444

Cox TL, Wohlgenant Mk (1986) Prices and quality effects in cross-sectional demand analysis. Am J Agric Econ 68:908–919

Crawford E, Kelly V, Jayne TS, Howard J (2003) Input use and market development in Sub-Saharan Africa: an overview. Food Policy 28:277–292

Dhungana BR, Nuthall PL, Nartea GV (2004) Measuring the economic inefficiency of Nepalese rice farms using data envelopment analysis. Aust J Agric Resour Econ 48:347–369

Erenstein O (2006) Intensification or extensification? Factors affecting technology use in peri-urban lowlands along an agro-ecological gradient in West Africa. Agric Syst 90:132–158

Erenstein O, Sumber J, Oswald A, Levasseur V, Kore H (2006) What future for integrated rice-vegetable production systems in West African lowlands? Agric Syst 88(2–3):376–394

Färe R, Grosskopf S (2000) Theory and Application of Directional Distance Functions. J Prod Anal 13:93–103

Färe R, Grosskopf S (2004) New Directions: Efficiency and Productivity. Springer Verlag, Berlin, 174 pp

Färe R (1988) Fundamentals of production theory. Springer Verlag, Berlin

Farrell MJ (1957) The measurement of productive efficiency. J R Stat Soc A CXX Part 3:253–290

Farrell MJ, Fieldhouse M (1962) Estimating efficient production functions under increasing returns to scale. J R Stat Soc A Gen 125(2):252–267

Fried HO, Lovell CAK, Schmidt SS, Yaisawarng S (2002) Accounting for Environmental Effects and Statistical Noise in Data Envelopment Analysis. J Prod Anal 17:157–174

Fukuyama H (2003) Scale characterizations in a DEA directional technology distance function framework. Eur J Oper Res 144:108–127

Gattoufi S, Oral M, Resiman A (2004) Data envelopment analysis literature: a bibliography update (1951–2001). Socio Econ Plann Sci 38:159–229

Gockowski J, Ndoumbe M (2004) The adoption of intensive monocrop horticulture in southern Cameroon. Agric Econ 30:195–202

Greene WH (2008) The econometric approach to efficiency analysis. In The measurement of productive efficiency and productivity growth. Fried, H.O., Lovell, K.C.A., and Schmidt, S.S. Oxford university press. 92–250

Horowitz JL (2001) The bootstrap and hypothesis tests in econometrics. J Econometrics 100:37–40

Huffman WE (1974) Decision making: the role of education. Am J Agric Econ 56:85–97

Jacoby HG (1993) Shadow wages and peasant family labour supply: an econometric application to the Peruvian Sierra. Rev Econ Stud 60(4):903–921

Jayne TS, Kelly V, Crawford E (2003) Fertilizer consumption trends in Sub-Saharan Africa. Policy Synthesis 69, Department of Agricultural Economics, Michigan State University, East Lansing. ( http://www.aec.msu.edu/agecon/fs2/psynindx.htm ).

Kelly VA (2005) Fertilizer demand in Sub-Saharan Africa: realizing the potential. Policy Synthesis 77, Department of Agricultural Economics, Michigan State University, East Lansing. ( http://www.aec.msu.edu/agecon/fs2/psynindx.htm )

Kumbhakar SC, Lovell KCA (2000) Stochastic frontier analysis. Cambridge University Press, 333p

Lavigne-Delville P, Boucher L (1998) Dynamiques paysannes de mise en culture des basfonds en Afrique de l’Ouest forestière. In: Cheneau-Loquay A, Leplaideur A (eds) Les rizicultures de l’Afrique de l’Ouest. CIRAD, Montpellier, pp 365–376

OECD (2008) Contribution to the United Nations Commission on sustainable development 16: towards sustainable agriculture. Pp 53

Ray SC (2004) The direction distance function and measurement of super-efficiency: an application to airlines data. Working paper 2004–16, University of Connecticut, Department of Economics Working Paper Series, 13 p

Resti A (2000) Efficiency measurement for multi-product industries: a comparison of classic and recent techniques based on simulated data. Eur J Oper Res 121:559–578

Richards P (1986) Coping With Hunger: Hazard and Experiment in an African rice-farming system. The London research series in geography 11. Allen & Unwin, London. 176

Sherlund SM, Barrett CB, Adesina AA (2002) Smallholder technical efficiency controlling for environmental production conditions. J Dev Econ 69:85–101

Sidhu SS, Baanante CA (1979) Farm-level fertilizer demand for Mexican wheat varieties in the Indian Punjab. Am J Agric Econ 61(3):455–462

Simar L, Wilson PW (2007) Estimation and inference in two-stage, semi-parametric models of production processes. J Econometrics 136:31–64

Spencer DSC, Byerlee D (1976) Technical change, labor use, and small farmer development: evidence from Sierra Leone. Am J Agric Econ 58:874–880

Stefanou SE, Saxena S (1988) Education, experience, and allocative efficiency: a dual approach. Am J Agric Econ 70:338–345

Tauer LW (1993) Short-run and long-run efficiencies of New-York dairy farms. Agric Resour Econ Rev 22(1):1–9

Thanassoulis E, Portela MCS, Despić O (2008) Data Envelopment Analysis: The mathematical programming approach to efficiency analysis. In The measurement of productive efficiency and productivity growth. Fried, H.O., Lovell, K.C.A., and Schmidt, S.S. Oxford university press. 251–420.

Tschirley D, Jayne TS (2008) Food crises and food markets: implications for emergency response in Southern Africa. Policy Synthesis, nº82, 6p. http://www.aec.msu.edu/agecon/fs2/psynindx.htm

Verlinden E, Soule BG (2003) Etude de la filière riz au Bénin : Diagnostic-Plan d’Action. PADSE. Pp 102. SOFRECO

Wadud A, White B (2000) Farm household efficiency in Bangladesh: a comparison of stochastic frontier and DEA methods. Appl Econ 32:1665–1673

Weinberger K, Lumpkin AT (2007) Diversification into horticulture and poverty reduction: a research agenda. World Dev 35(8):1464–1480

Welch F (1970) Education in production. J Polit Econ 78:35–59

Wilson PW (2003) Testing independence in models of productive efficiency. J Prod Anal 20:361–390

Xue M, Harker PT (1999) Overcoming the inherent dependency of DEA efficiency scores: a bootstrap approach. Unpublished Working Paper, Wharton Financial Institutions Center, University of Pennsylvania

Acknowledgments

Data collection for this research was funded by the World Vegetable Centre (AVRDC). We sincerely thank Virginie Levasseur for the fruitful collaboration. The institutional support from Benin’s National Institute for Agricultural Researches (INRAB) is highly acknowledged. In this respect, the authors thank Vincent Mama and Françoise Komlan for their helpful institutional assistance.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Singbo, A.G., Lansink, A.O. Lowland farming system inefficiency in Benin (West Africa): directional distance function and truncated bootstrap approach. Food Sec. 2, 367–382 (2010). https://doi.org/10.1007/s12571-010-0086-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12571-010-0086-z