Abstract

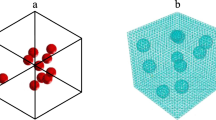

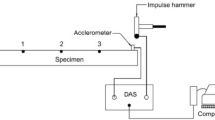

Silicon carbide particle-reinforced aluminum matrix composite has been widely used in the military and aerospace industry due to its special performance; however, there remain many problems in processing. The present paper introduces an ultrasonic vibration tensile device with a view to investigating an ultrasonic vibration tensile specimen. The results show that there are three major stages in the change in stress of the material under ultrasonic vibration: the ultrasonic stress superposition effect, softening effect, and Hall–Petch strengthening effect, these three effects occupy different proportions in different tensile stages. In addition, increasing the frequency of ultrasonic vibration increased the degree of stress reduction. Increasing the ultrasonic vibration amplitude reduced the fracture strength of the material. Comparison of the fracture morphology shows that the conventional condition was mainly interfacial peeling of SiC particles, and cleavage of the fracture occurred under ultrasonic vibration conditions.

Similar content being viewed by others

References

Aristizabal, K., Katzensteiner, A., Leoni, M., Mücklich, F., & Suáreza, S. (2019). Evolution of the lattice defects and crystalline domain size in carbon nanotube metal matrix composites processed by severe plastic deformation. Materials Characterization, 154, 344–352.

Owoeye, S. S., Folorunso, D. O., Oji, B., & Borisade, S. G. (2018). Zinc-aluminum (ZA-27)-based metal matrix composites: A review article of synthesis, reinforcement, microstructural, mechanical, and corrosion characteristics. International Journal of Advanced Manufacturing Technology, 100(1–4), 373–380.

Quintanilla, F. H., & Leckey, C. A. C. (2018). Lebedev scheme for ultrasound simulation in composites. Ultrasonics, 86, 28–40.

Avettand-Fènoël, M. N., & Simar, A. (2016). A review about friction stir welding of metal matrix composites. Materials Characterization, 120, 1–17.

Gao, Y. Y., Qiu, F., Geng, R., Zhao, W. X., Yang, D. L., Zuo, R., et al. (2018). Preparation and characterization of the Al–Cu–Mg–Si–Mn composites reinforced by different surface modified SiCp. Materials Characterization, 141, 156–162.

Teng, X. G., Chen, W. Q., Huo, D. H., Shyha, I., & Lin, C. (2018). Comparison of cutting mechanism when machining micro and nanoparticles reinforced SiC/Al metal matrix composites. Composite Structures, 203, 636–647.

Gatea, S., Ou, H. G., & McCartney, G. (2018). Deformation and fracture characteristics of Al6092/SiC/17.5p metal matrix composite sheets due to heat treatments. Materials Characterization, 142, 365–376.

Wang, T., Xie, L. J., & Wang, X. B. (2015). Simulation study on defect formation mechanism of the machined surface in milling of high-volume fraction SiCp/Al composite. International Journal of Advanced Manufacturing Technology, 79(5–8), 1185–1194.

Zha, H. T., Feng, P. F., Zhang, J. F., Yu, D. W., & Wu, Z. J. (2018). Material removal mechanism in rotary ultrasonic machining of high-volume fraction SiCp/Al composites. International Journal of Advanced Manufacturing Technology, 97(5–8), 2099–2109.

Liu, C. S., Zhao, B., Gao, G. F., & Jiao, F. (2002). Research on the characteristics of the cutting force in the vibration cutting of a particle-reinforced metal matrix composites SiCp/Al. Journal of Materials Processing Technology, 129(1), 196–199.

Xiang, D. H., Liu, H. T., Jiang, X., Liang, S., & Yang, G. B. (2013). Study on tool wear of high-volume fraction SiCp/Al composites with ultrasonic vibration high speed milling. Applied Mechanics and Materials, 252, 198–201.

Xiang, D. H., Yue, G. X., Liu, H. T., & Zhao, B. (2012). Study on surface roughness in ultrasonic high-speed milling of SiCp/Al composites. Materials Science Forum, 723, 214–218.

Zhou, M., & Zheng, W. (2016). A model for grinding forces prediction in ultrasonic vibration assisted grinding of SiCp/Al composites. International Journal of Advanced Manufacturing Technology, 87(9–12), 3321–3324.

Jia, Y. X., Wang, G. C., & Zhao, Z. D. (1999). Influence of plastic working on the microstructure of SiCp/Al composite. Aeronautical Manufacturing Technology, 4, 23–24.

Sidhu, S. S., Batish, A., & Kumar, S. (2013). Fabrication and electrical discharge machining of metal-matrix composites: A review. Journal of Reinforced Plastics and Composites, 32(17), 1310–1320.

Jiao, K., Huang, S., & Xu, L. (2015). Feature classification of high-volume SiCp/Al composites under the condition of two-dimensional cutting based on cluster analysis theory. International Journal of Advanced Manufacturing Technology, 78(5–8), 677–686.

Yuan, Z., Li, F., & Xue, F. (2015). An investigation of micro-mechanical properties of Al matrix in SiC/Al composite by indentation experiments. Journal of Materials Engineering and Performance, 24(2), 654–663.

Yuan, Z., Li, F., & Chen, B. (2014). Further investigation of particle reinforced aluminum matrix composites by indentation experiments. Journal of Materials Research., 29(4), 586–595.

Wang, J. P. (2015). Theoretical and experimental research of constitutive model of ultrasonic vibration assisted forming. Thesis submitted to the faculty of the Shanghai Jiao Tong University in partial fulfillment of the requirements for the degree of Master of Materials Engineering.

Yang, T. Q. (1990). Viscoelastic mechanics. Wuhan: Huazhong University of Technology Press.

Long, X. N. (1999). Soil plasticity mechanics. Hangzhou: Zhejiang University Press.

Wang, C. J., Liu, Y., & Guo, B. (2016). Acoustic softening and stress superposition in ultrasonic vibration assisted uniaxial tension of copper foil: Experiments and modeling. Materials & Design, 112, 246–253.

Yao, Z. H., Kim, G. Y., & Wang, Z. H. (2012). Acoustic softening and residual hardening in aluminum: Modeling and experiments. International Journal of Plasticity, 39, 75–78.

Zhang, Y. D. (1993). Ultrasonic machining and its application. Beijing: National Defense Industry Press.

Shi, D. K. (1998). Dislocation and material strength. Xi'an: Xi'an Jiao tong University Press.

Liu, Y., Suslov, S., & Han, Q. (2012). Microstructure of the pure copper produced by upsetting with ultrasonic vibration. Materials Letters, 67(1), 52–55.

Zhou, H. Y., Cui, H. Z., & Qin, Q. H. (2017). A comparative study of mechanical and microstructural characteristics of aluminum and titanium undergoing ultrasonic assisted compression testing. Materials Science & Engineering A, 682, 376–388.

Panin, A. V., Son, A. A., & Pochivalov, Y. I. (2004). The effect of ultrasonic treatment on mechanical behavior of titanium and steel specimens. Theoretical & Applied Fracture Mechanics, 41(1), 163–172.

Lin, Z. M. (1987). Principle and design of ultrasonic horn. Beijing: Science Press.

Green, C. H. (2000). Stress amplitude analysis in a generalized ultrasonic fatigue dumbbell specimen. Journal of Physics D-Applied Physics, 24(3), 469–477.

Matikas, T. E. (2001). Specimen design for fatigue testing at very high frequencies. Journal of Sound and Vibration, 247(4), 673–681.

Green, C. H. (1979). Radius optimization in an ultrasonic specimen with a circular gauge profile. Journal of Physics D-Applied Physics, 12(7), 1191–1194.

Green, C. H., & Guiu, F. (1976). The ultrasonic fatigue testing of specimens much shorter than the testing frequency half-wavelength of the material. Journal of Physics D-Applied Physics, 9(6), 1071–1078.

Nevill, G. E. (1975). Effect of vibration on the yield strength of a low carbon steel. Houston: The Rice Institute.

Yao, Z., Kim, G. Y., & Faidley, L. A. (2010). Micro pin extrusion of metallic materials assisted by ultrasonic vibration. In ASME 2010 international manufacturing science and engineering conference. American Society of Mechanical Engineers (pp. 647–651).

Wang, J. P. (2015). Theoretical and experimental research of constitutive model of ultrasonic vibration assisted formin. Thesis submitted to the faculty of the Shanghai Jiao Tong University in partial fulfillment of the requirements for the degree of Master of Materials Engineering.

Fartashvand, V., Abdullah, A., & Sadough, S. A. (2016). Investigation of Ti–6Al–4V alloy acoustic softening. Ultrasonics Sonochemistry, 38, 744–749.

Yao, Z., Kima, G. Y., & Faidley, L. A. (2012). Acoustic softening and residual hardening in aluminum: modeling and experiments. International Journal of Plasticity, 39(39), 75–87.

Jiang, L. B. (2014). Experiment and simulation on vibration aided tensile and compressive process of aluminum alloy. Thesis submitted to the faculty of the Shan Dong University in partial fulfillment of the requirements for the degree of Master of Material Processing Engineering.

Bai, Y., & Yang, M. (2015). Deformation analysis of brass in micro compression test with presence of ultrasonic vibration. International Journal of Precision Engineering Manufacturing, 16(4), 685–691.

Acknowledgements

This research was supported financially by the National Natural Science Foundation of China (No. 51975188), Henan Provincial Natural Science Foundation of China (No. 182300410200), and Open Research Fund of State Key Laboratory of High-Performance Complex Manufacturing, Central South University (No. Kfkt2017-09).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiang, DH., Zhang, ZM., Wu, BF. et al. Effect of Ultrasonic Vibration Tensile on the Mechanical Properties of High-Volume Fraction SiCp/Al Composite. Int. J. Precis. Eng. Manuf. 21, 2051–2066 (2020). https://doi.org/10.1007/s12541-020-00335-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-020-00335-7