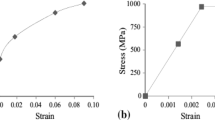

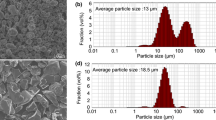

Under repeated impact loading, SiC particle-reinforced aluminum matrix composites (SiCp/Al) experience severe plastic strains, which can lead to local changes in their microstructure. Microstructural variations have a significant effect on the dynamic behavior of SiCp/Al composites under subsequent impact loading. Their microstructure was analyzed by scanning electron microscopy (SEM). Then the dynamic compressive properties of SiCp/Al composites were studied using the split Hopkinson pressure bar (SHPB), and the dynamic compression stress–strain curve for each impact was plotted. The SEM results revealed that an increase in the impact cycle led to enhanced cracking of particles and interface delamination. The SHPB results showed that the yield stress and flow stress increased significantly for the first three cycles and then remained constant. The material behavior during the first three cycles can be attributed to strain hardening of the metal matrix, while its stability at the subsequent stages is the combined effect of strain hardening of the metal matrix and damage accumulation in the composite.

Similar content being viewed by others

References

W. D. Song, J. G. Ning, and J. Wang, “Numerical simulation on tensile property of TiC particle reinforced titanium matrix composite,” Mater. Res. Innovat., 15, Issue s1, s171–s174 (2011).

C. X. Liu, J. L. Sun, and M. H. Yao, “Addition of rare earth and diopside to improve performances of alumina matrix ceramic materials,” Mater. Res. Innovat., 17, Issue 4, 293–297 (2013).

S. Ozden, R. Ekici, and F. Nair, “Investigation of impact behaviour of aluminium based SiC particle reinforced metal–matrix composites,” Composites Part A: Appl. Sci. Manuf., 38, No. 2, 484–494 (2007).

Z. H. Tan, B. J. Pang, B. Z. Gai, et al., “The dynamic mechanical response of SiC particulate reinforced 2024 aluminum matrix composites,” Mater. Lett., 61, No. 23-24, 4606–4609 (2007).

L. H. Dai, L. F. Liu, and Y. L. Bai, “Effect of particle size on the formation of adiabatic shear band in particle reinforced metal matrix composites,” Mater. Lett., 58, No. 11, 1773–1776 (2004)

V. Sivananth, S. Vijayarangan, and N. Rajamanickam, “Evaluation of fatigue and impact behavior of titanium carbide reinforced metal matrix composites,” Mater. Sci. Eng. A, 597, 304–313 (2014).

E. Guades, T. Aravinthan, A. Manalo, and M. Islam, “Damage modelling of repeatedly impacted square fibre-reinforced polymer composite tube,” Mater. Design, 47, 687–697 (2013).

W. A. de Morais, S. N. Monteiro, and J. R. M. d’Almeida, “Evaluation of repeated low energy impact damage in carbon–epoxy composite materials,” Compos. Struct., 67, No. 3, 307–315 (2005).

O. S. David-West, D. H. Nash, and W. M. Banks, “An experimental study of damage accumulation in balanced CFRP laminates due to repeated impact,” Compos. Struct., 83, No. 3, 247–258 (2008).

E. Sevkat, B. Liaw, F. Delale, and B. B. Raju, “Effect of repeated impacts on the response of plain-woven hybrid composites,” Composites Part B: Engineering, 41, No. 5, 403–413 (2010).

J. Baucom, M. Zikry, and A. Rajendran, “Low-velocity impact damage accumulation in woven S2-glass composite systems,” Compos. Sci. Technol., 66, No. 10, 1229– 1238 (2006).

J. Lai and W. Sun, “Dynamic damage and stress-strain relations of ultra-high performance cementitious composites subjected to repeated impact,” Sci. China Technol. Sci., 53, No. 6, 1520–1525 (2010).

G. Kermouche, G. Pacquaut, C. Langlade, and J.-M. Bergheau, “Investigation of mechanically attrited structures induced by repeated impacts on an AISI1045 steel,” CR Mecan., 339, No. 7-8, 552–562 (2011).

A. C. Sekkal, C. Langlade, and A. B. Vannes, “Tribologically transformed structure of titanium alloy (TiAl6V4) in surface fatigue induced by repeated impacts,” Mater. Sci. Eng. A, 393, No. 1-2, 140–146 (2005).

Y. Þahin, “Abrasive wear behaviour of SiC/2014 aluminium composite,” Tribol. Int., 43, No. 5-6, 939–943 (2010).

H. M. Zakaria, “Microstructural and corrosion behavior of Al/SiC metal matrix composites,” Ain Shams Eng. J., 5, Issue 3, 831–838 (2014).

H. Meng and J. Li, “Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments,” Int. J. Impact Eng., 28, 537–555 (2005).

C. S. March, F. H. Cao, M. Kouzeli, and A. Mortehsen, “Quasistatic and dynamic compression of aluminum-oxide particle reinforced pure aluminum,” Mater. Sci. Eng. A, 337, 202–211 (2002).

S. Nemat-Nasser, Y.-F. Li, and J. B. Isaacs, “Experimental/computational evaluation of flow stress at high strain rates with application to adiabatic shear banding,” Mech. Mater., 17, No. 2-3, 111–134 (1994).

Y. Xia and Y. Zhou, “Recovery experimental techniques of tensile impact,” Acta Mech. Sin., 12, No. 3, 244–50 (1996).

Acknowledgments

The work was supported by the Fundamental Research Funds for the Central Universities (WUT: 2013-1a-033 and 2013-1a-029), and National High-Tech R&D Program of China (863 Program, No. 2012AA051104).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 74 – 81, January – February, 2015.

Rights and permissions

About this article

Cite this article

Cao, D.F., Liu, L.S., Liu, Q.W. et al. Compressive Properties of SiC Particle-Reinforced Aluminum Matrix Composites Under Repeated Impact Loading. Strength Mater 47, 61–67 (2015). https://doi.org/10.1007/s11223-015-9628-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-015-9628-0