Abstract

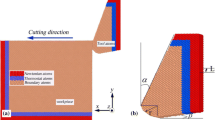

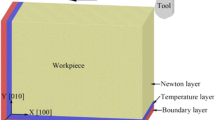

Molecular dynamics, an effective method to gain an insight into nanometric behaviour of materials, was employed to study the nano-cutting behaviour of single crystal Ni3Al in nanometric scale. In this paper, comparisons were made for compressive/tensile stress, subsurface damage and surface roughness with three rake angles of a diamond tool. Subsurface damage was partitioned by region and studied with work hardening in detail. A model for precise characterization of surface roughness was established with consideration of local surface fluctuation. Simulation results showed that the chip thickness increased as rake angle changed from negative to positive, and the boundary formed between tensile and compressive stress was in consistent with the glide direction of stacking fault. Subsurface damage decreased as the increase of rake angle, and regular glide planes of stacking faults were found in front of the cutting tool. Further, the pinned dissociated 1/2 < 110 > superpartial dislocation with anti-phase boundary was demonstrated. The model was tested and characterized by implanted pits on perfect surface. Results showed that surface roughness can be well characterized, and an evident discrepancy was observed among three rake angles, especially for 30° rake angle, which showed an distinct smooth surface compared with the others.

Similar content being viewed by others

References

Brinksmeier, E., & Riemer, O. (1998). Measurement of optical surfaces generated by diamond turning. International Journal of Machine Tools and Manufacture,38(5–6), 699–705. https://doi.org/10.1016/S0890-6955(97)00120-X.

Balasubramaniam, R., Sarepaka, V., Subbiah, S. (2017). Diamond turn machining: Theory and practice. Boca Raton: CRC Press.http://www.crcpress.com/Diamond-Turn-Machining-Theory-and-Practice/Balasubramaniam-Sarepaka-Subbiah/p/book/9781498787581.

Goel, S., Luo, X., Agrawal, A., & Reuben, L. R. (2015). Diamond machining of silicon: A review of advances in molecular dynamics simulation. International Journal of Machine Tools and Manufacture,88, 131–164. https://doi.org/10.1016/j.ijmachtools.2014.09.013.

Goel, S., Chavoshi, S. Z., & Murphy, A. (2017). Molecular dynamics simulation (MDS) to study nanoscale machining processes. In V. K. Jain (Ed.), Nanofinishing science and technology: Basic and advanced finishing and polishing processes (Micro and nanomanufacturing series). Boca Raton: CRC Press. https://doi.org/10.1201/9781315404103-26.

Lau, D., Jian, W., Yu, Z., & Hui, D. (2018). Nano-engineering of construction materials using molecular dynamics simulations: Prospects and challenges. Composites: Part B,143, 282–291. https://doi.org/10.1016/j.compositesb.2018.01.014.

Xu, F. F., Fang, F. Z., & Zhang, X. D. (2018). Effects of recovery and side flow on surface generation in nano-cutting of single crystal silicon. Computational Materials Science,143, 133–142. https://doi.org/10.1016/j.commatsci.2017.11.002.

Zong, W. J., Huang, Y. H., Zhang, Y. L., & Sun, T. (2014). Conservation law of surface roughness in single point diamond turning. International Journal of Machine Tools and Manufacture,84, 58–63. https://doi.org/10.1016/j.ijmachtools.2014.04.006.

Pei, Q. X., Lu, C., Lee, H., & Zhang, Y. W. (2009). Study of materials deformation in nanometric cutting by large-scale molecular dynamics simulations. Nanoscale Research Letters,4(5), 444–451. https://doi.org/10.1007/s11671-009-9268-z.

Sharma, A., Datta, D., & Balasubramaniam, R. (2018). An investigation of tool and hard particle interaction in nanoscale cutting of copper beryllium. Computational Materials Science,145, 208–223. https://doi.org/10.1016/j.commatsci.2018.01.011.

Ren, J. Q., Zhao, J. S., Dong, Z. G., & Liu, P. K. (2015). Molecular dynamics study on the mechanism of AFM-based nanoscratching process with water-layer lubrication. Applied Surface Science,346, 84–98. https://doi.org/10.1016/j.apsusc.2015.03.177.

Zhang, J., Geng, L., Yan, Y., & Sun, T. (2015). Effect of tool geometry in nanometric cutting of nanotwinned Cu: A molecular dynamics study. International Journal of Nanomanufacturing,11(3–4), 138–149. https://doi.org/10.1504/IJNM.2015.071910.

Pei, Q. X., Lu, C., Fang, F. Z., & Wu, H. (2006). Nanometric cutting of copper: A molecular dynamics study. Computational Materials Science,37(4), 434–441. https://doi.org/10.1016/j.commatsci.2005.10.006.

Ranganath, M. S. (2014). Vipin, Effect of Rake Angle on Surface Roughness in CNC Turning. International Journal of Advance Research and Innovation,2(2), 522–530.

Geng, Y., Yan, Y., Brousseau, E., & Sun, Y. (2017). AFM tip-based mechanical nanomachining of 3D micro and nano-structures via the control of the scratching trajectory. Journal of Materials Processing Technology,248, 236–248. https://doi.org/10.1016/j.jmatprotec.2017.05.028.

Li, J., Fang, Q. H., Liu, Y. W., & Zhang, L. (2014). A molecular dynamics investigation into the mechanisms of subsurface damage and material removal of monocrystalline copper subjected to nanoscale high speed grinding. Applied Surface Science,303, 331–343. https://doi.org/10.1016/j.apsusc.2014.02.178.

Sharma, A., Datta, D., & Balasubramaniam, R. (2018). Molecular dynamics simulation to investigate the orientation effects on nanoscale cutting of single crystal copper. Computational Materials Science,153, 241–250. https://doi.org/10.1016/j.commatsci.2018.07.002.I.

Liu, H. T., Zhu, X. F., Sun, Y. Z., & Xie, W. K. (2017). Evolution of stacking fault tetrahedral and work hardening effect in copper single crystals. Applied Surface Science,422, 413–419. https://doi.org/10.1016/j.apsusc.2017.06.059.

Xiao, G., To, S., & Zhang, G. (2015). Molecular dynamics modelling of brittle-ductile cutting mode transition: Case study on silicon carbide. International Journal of Machine Tools and Manufacture,88, 214–222. https://doi.org/10.1016/j.ijmachtools.2014.10.007.

Cai, M. B., Li, X. P., & Rahman, M. (2007). Study of the mechanism of nanoscale ductile mode cutting of silicon using molecular dynamics simulation. International Journal of Machine Tools and Manufacture,47(1), 75–80. https://doi.org/10.1016/j.ijmachtools.2006.02.016.

Komanduri, R., Lucca, D. A., & Tani, Y. (1997). Technological advances in fine abrasive processes. CIRP Annals,46(2), 545–596. https://doi.org/10.1016/S0007-8506(07)60880-4.

Uezaki, K., Shimizu, J., & Zhou, L. (2014). Development of metal cutting process accompanied by a localized compressive hydrostatic stress field formation: Examination by molecular dynamics simulation. Precision Engineering,38(2), 371–378. https://doi.org/10.1016/j.precisioneng.2013.12.002.

Wang, Y. C., Shi, J., & Ji, C. H. (2014). A numerical study of residual stress induced in machined silicon surfaces by molecular dynamics simulation. Applied Physics A: Materials Science and Processing,115(4), 1263–1279. https://doi.org/10.1007/s00339-013-7977-8.

Guo, Y. B., Liang, Y. C., Chen, M. J., Bai, Q. S., & Lu, L. H. (2010). Molecular dynamics simulations of thermal effects in nanometric cutting process. Science China Technological Sciences,53(3), 870–874. https://doi.org/10.1007/s11431-009-0243-9.

Du, J. P., Wang, C. Y., & Yu, T. (2012). Construction and application of multi-element EAM potential (Ni–Al–Re) in γ/γ′ Ni-based single crystal superalloys. Modelling and Simulation in Materials Science and Engineering,21(1), 015007. https://doi.org/10.1088/0965-0393/21/1/015007.

Xiong, K., Lu, H., & Gu, J. (2016). Atomistic simulations of the nanoindentation-induced incipient plasticity in Ni3Al crystal. Computational Materials Science,115, 214–226. https://doi.org/10.1016/j.commatsci.2015.12.045.

Mauer, F. A., Munro, R. G., Piermarini, G. J., Block, S., & Dandekar, D. P. (1985). Compression studies of a nickel-based superalloy. Journal of Applied Physics,58, 3727–3730. https://doi.org/10.1063/1.335636.

Yoo, M. H., Daw, M., & Baskes, M. I. (1989). Atomistic simulation of superdislocation dissociation in Ni3Al. In V. Vitek & D. J. Srolovitz (Eds.), Atomistic simulation of materials. Boston: Springer. https://doi.org/10.1007/978-1-4684-5703-2_41.

Karnthaler, H. P., Mühlbacher, E. T., & Rentenberger, C. (1996). The influence of the fault energies on the anomalous mechanical behaviour of Ni3Al alloys. Acta Materialia,44(2), 547–560. https://doi.org/10.1016/1359-6454(95)00191-3.

Dandekar, C. R., & Shin, Y. C. (2011). Molecular dynamics based cohesive zone law for describing Al-SiC interface mechanics. Composites: Part A,42(4), 355–363. https://doi.org/10.1016/j.compositesa.2010.12.005.

Chang, W. Y., Fang, T. H., Lin, S. J., & Huang, J. J. (2010). Nanoindentation response of nickel surface using molecular dynamics simulation. Molecular Simulation,36(11), 815–822. https://doi.org/10.1080/08927021003677761.

Tersoff, J. (1994). Chemical order in amorphous silicon carbide. Physical Review B,49(23), 16349–16352. https://doi.org/10.1103/PhysRevB.49.16349.

Nguyen, T. D., & Plimpton, S. J. (2015). Accelerating dissipative particle dynamics simulations for soft matter systems. Computational Materials Science,100, 173–180.

Lion, T. W., & Allen, R. J. (2012). Computing the local pressure in molecular dynamics simulations. Journal of Physics: Condensed Matter.,24(24), 284133. https://doi.org/10.1088/0953-8984/24/28/284133.

Zhou, M. (2003). A new look at the atomic level virial stress: on continuum-molecular system equivalence. Proceedings of the Royal Society of London. Series A,459(2037), 2347–2392. https://doi.org/10.1098/rspa.2003.1127.

Egami, T. (2011). Atomic level stresses. Progress in Materials Science,56(6), 637–653. https://doi.org/10.1016/j.pmatsci.2011.01.004.

Rycroft, C. H. (2009). VORO plus plus: A three-dimensional voronoi cell library in C plus. Chaos,19(4), 041111.

Faken, D., & Jónsson, H. (1994). Systematic analysis of local atomic structure combined with 3D computer graphics. Computational Materials Science,2(2), 279–286. https://doi.org/10.1016/0927-0256(94)90109-0.

Stukowski, A. (2010). Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool. Modelling and Simulation in Materials Science and Engineering,18(1), 2154–2162. https://doi.org/10.1088/0965-0393/18/1/015012.

Kelchner, C. L., Plimpton, S. J., & Hamilton, J. C. (1998). Dislocation nucleation and defect structure during surface indentation. Physical review B,58(17), 11085–11088. https://doi.org/10.1103/PhysRevB.58.11085.

Staton-Bevan, A. E., & Rawlings, R. D. (1975). The deformation behavior of single crystal Ni3 (Al, Ti). Physica Status Solidi A,29(2), 613–622. https://doi.org/10.1002/pssa.2210290232.

Milligan, W. W., & Antolovich, S. D. (1989). On the mechanism of cross slip in Ni3Al. Metallurgical Transactions A,20(12), 2811–2818. https://doi.org/10.1007/BF02670173.

Thompson, N. (2002). Dislocation nodes in face-centred cubic lattices. Proceedings of the Physical Society Section B.,66(6), 481. https://doi.org/10.1088/0370-1301/66/6/304.

Paidar, V., Pope, D. P., & Vitek, V. (1984). A theory of the anomalous yield behavior in L12 ordered alloys. Acta Metallurgica,32(3), 435–448. https://doi.org/10.1016/0001-6160(84)90117-2.

Flinn, P. A. (1960). Theory of deformation in superlattices. Transactions of the American Institute of Mining and Metallurgical Engineers,218, 145–154.

Acknowledgements

This work was supported by a Grant from the National Natural Science Fundation of China (No.51865027) and the Program for Changjiang Scholars and Innovative Research Team in University of Ministry of Education of China (No.IRT_15R30) and Hongliu First-class Disciplines Development Program of Lanzhou University of Technology.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, Rc., Qi, Yn., Zhu, Zx. et al. Molecular Dynamics Simulation to Investigate the Rake Angle Effects on Nanometric Cutting of Single Crystal Ni3Al. Int. J. Precis. Eng. Manuf. 21, 711–724 (2020). https://doi.org/10.1007/s12541-019-00249-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00249-z