Abstract

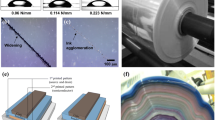

Coiling is a method used to store long and thin products, such as a wire or film, made out of steel, plastic, or rubber, in a volumeefficient manner, and is the final phase of most roll product manufacturing systems. Internal stress in a roll product is exerted during this process, and can decrease the productivity by causing buckling or telescoping. Therefore, this issue has warranted interest in the roll-to-roll manufacturing process, and significant effort has gone into improving the internal stress while avoiding the loosening and slippage between adjacent coiled layers. In this paper, we review various studies on the dynamics of internal stresses, as well as the control techniques used to improve the stress and quality of a roll product. Initially, the various defects occurring in roll products and a radial stress generating such defects are introduced, and mathematical models applied to analyze the dynamics of stress with respect to the characteristics of the coiled materials and the coiling process conditions are compared. In addition, techniques to control the internal stress are introduced. Finally, tension profiles used in the coiled tension control technique are introduced and compared. This review will be useful for understanding the defects that occur in roll products due to internal stress, as well as alternative methods to improve the quality of a coiled roll.

Similar content being viewed by others

Abbreviations

- εh :

-

hoop strain

- εr :

-

radial strain

- u:

-

radial displacement

- r:

-

ratio radius of wound roll to core radius

- R:

-

outside radius of fully wound roll

- σr :

-

radial stress

- σh :

-

hoop stress

- Er :

-

modulus of elasticity of the roll in the radial direction

- Eh :

-

modulus of elasticity of the roll in the hoop direction

- μr :

-

Poisson’s ratio in the radial direction

- μh :

-

Poisson’s ratio in the hoop direction

- Tw :

-

winding tension

- σw :

-

winding stress

- I(r, p):

-

winding integrals in terms of hypergeometric functions in Yagoda model

- a:

-

non-dimensional constant related to elastic material properties of roll in Yagoda model

- δ:

-

non-dimensional constant related to elastic material properties of core in Yagoda model

- μ:

-

coefficient of friction

- N:

-

nip load

- h:

-

thickness of film

- s:

-

radial location of the current outer wrap of the winding roll

- Γ:

-

constant related to boundary conditions of radial stress of roll in Lee model

- sij :

-

compliance of film

- σg * :

-

effective residual stress considering gravity force of film

- β:

-

non-dimensional constant related to elastic material properties of roll in Lee model

- ρ:

-

density of film

- g:

-

gravitational acceleration

- εθ,b :

-

bending stress in wound layer

- εw :

-

strain of film in winding section

- εu:

-

strain of film in upstream of winding section

- Vw :

-

film velocity in winding section

References

Jeon, S. W., Kim, C., and Kim, C. H., “Control and Measurement of Doctoring Angle at Deformed State in Doctoring Apparatus for Printed Electronics,” International Journal of Precision Engineering and Manufacturing, vol. 18, no. 5, pp. 633–639, 2017.

Yim, C., Greco, K., Sandwell, A., and Park, S. S., “Eco-friendly and Rapid Fabrication Method for Producing Polyethylene Terephthalate (PET) Mask Using Intensive Pulsed Light,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 4, no. 2, pp. 155–159, 2017.

Park, J., Shin, K., and Lee, C., “Roll-to-Roll Coating Technology and Its Applications: A Review,” International Journal of Precision Engineering and Manufacturing, vol. 17, no. 4, pp. 537–550, 2016.

Yim, C., Greco, K., Sandwell, A., and Park, S. S., “Eco-friendly and Rapid Fabrication Method for Producing Polyethylene Terephthalate (PET) Mask Using Intensive Pulsed Light,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 4, no. 2, pp. 155–159, 2017.

Lee, J., Park, S., Park, J., Cho, Y. S., Shin, K.-H., and Lee, D., “Analysis of Adhesion Strength of Laminated Copper Layers in Roll-to-Roll Lamination Process,” International Journal of Precision Engineering and Manufacturing, vol. 16, no. 9, pp. 2013–2020, 2015.

Du, Z.-C., Hou, H.-F., Wang, Z.-G., and Yang, J.-G., “Thermal Deformation Isolation for Satellite Platforms via Flexible Connections,” International Journal of Precision Engineering and Manufacturing, vol. 18, no. 12, pp. 1821–1832, 2017.

Lee, J., Kim, H.-C., Choi, J.-W., and Lee, I. H., “A Review on 3D Printed Smart Devices for 4D Printing,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 4, no. 3, pp. 373–383, 2017.

Vahabli, E. and Rahmati, S., “Application of an RBF Neural Network for FDM Parts’ Surface Roughness Prediction for Enhancing Surface Quality,” International Journal of Precision Engineering and Manufacturing, vol. 17, no. 12, pp. 1589–1603, 2016.

Lee, J.-C., Kim, W., and Choi, S., “Fabrication of A SERS-Encoded Microfluidic Paper-Based Analytical Chip for the Point-of-Assay of Wastewater,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 4, no. 2, pp. 221–226, 2017.

Kim S. and Lee, C., “A Study on the Fabrication of Slot-Die Coater Based on Polydimethylsiloxane Using Three-Dimensional Printing Technique,” Journal of the Korean Society for Precision Engineering, Vol. 34 No. 8, pp. 537–543, 2017.

Lee, J., Park, J., Jeong, H., Shin, K.-H., and Lee, D., “Optimization of Printing Conditions for Microscale Multiline Printing in Continuous Roll-to-Roll Gravure Printing,” Journal of Industrial and Engineering Chemistry, vol. 42, pp. 131–141, 2016.

Lee, C., “Novel Approach to Predict the Varying Thicknesses of a PVA Film during a Roll-to-Roll Process,” International Journal of Mechanical Sciences, Vol. 92, No. pp. 52–69, 2015.

Roisum, D. R., “The Mechanics of Winding,” Tappi Press, 1994.

Yanabe, S., Takahashi, K., and Yamashita, T., “Web Winding Simulation and Wound Roll Stresses,” Journal of Advanced Mechanical Design, Systems, and Manufacturing, vol. 4, no. 1, pp. 281–289, 2010.

Kim, S. and Lee, C., “Study on the Radial Stress Considering Mechanical Characteristics of Substrate in Wound Rolls,” Journal of the Korean Society for Precision Engineering, vol. 33, no. 2, pp. 115–119, 2016.

Hashimoto, H., “Intelligent Winding Machine of Plastic Films for Preventing Both Wrinkles and Slippages,” Modern Mechanical Engineering, vol. 6, no. 1, pp. 20–31, 2016.

Kim, S.-H., Lee, M.-Y., Woo, K., Youn, H., Lee, T.-M., et al., “A Study on Thin Film Uniformity in a Roll-to-Roll Thermal Evaporation System for Flexible OLED Applications,” International Journal of Precision Engineering and Manufacturing, vol. 18, no. 8, pp. 1111–1117, 2017.

Kim, H.-S., Lee, Y.-S., Yang, S.-M., and Kang, H. Y., “Structural Analysis on Variable Characteristics of Automotive Seat Frame by FEA,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 3, no. 1, pp. 75–79, 2016.

Ly, S. T. and Kim, J. Y., “4D Printing-Fused Deposition Modeling Printing with Thermal-Responsive Shape Memory Polymers,” International Journal of Precision Engineering and Manufacturing Green Technology, vol. 4, no. 3, pp. 267–272, 2017.

McDonald, J. D. and Menard, A., “Layer-to-Layer Slippage within Paper Rolls during Winding,” Journal of Pulp and Paper Science, vol. 25, no. 4, pp. 148, 1999.

Lee, C.-W. and Shin, K.-H., “A Study on Taper-Tension Control Considering Telescoping in the Winding System,” IEEE Transactions on Industry Applications, vol. 46, no. 2, pp. 687–693, 2010.

Lee, C., Kang, H., and Shin, K., “Advanced Taper Tension Method for the Performance Improvement of a Roll-to-Roll Printing Production Line with a Winding Process,” International Journal of Mechanical Sciences, vol. 59, no. 1, pp. 61–72, 2012.

McDonald, J. D., “Crepe Wrinkle Formation during Reeling and Winding,” J-for-Journal of Science & Technology for Forest Products and Processes, vol. 4, no. 1, pp. 22–28, 2014.

Dehui, W., Chen, C., Xiumiao, Y., Xuesong, L., and Yimin, H., “Optimization of Taper Winding Tension in Roll-to-Roll Web Systems,” Textile Research Journal, vol. 84, no. 20, pp. 2175–2183, 2014.

Lin, P. M. and Wickert, J. A., “Corrugation and Buckling Defects in Wound Rolls,” Journal of Manufacturing Science and Engineering, vol. 128, no. 1, pp. 56–64, 2006.

Lee, C., Kang, H., Kim, H., and Shin, K., “Effect of Taper Tension Profile on the Telescoping in a Winding Process of High Speed Roll to Roll Printing Systems,” Journal of Mechanical Science and Technology, vol. 23, no. 11, pp. 3036–3048, 2009.

Hashimoto, H., Jeenkour, P., and Mongkolowongrojn, M., “Optimum Winding Tension and Nip-Load into Wound Webs for Protecting Wrinkles and Slippage,” Journal of Advanced Mechanical Design, Systems, and Manufacturing, vol. 4, no. 1, pp. 214–225, 2010.

Altmann, H. C., “Formulas for Computing the Stresses in Center-Wound Rolls,” Tappi Journal, vol. 51, no. 4, pp. 176–179, 1968.

Yagoda, H. P., “Integral Formulas for Wound Rolls,” Mechanics Research Communications, vol. 7, no. 2, pp. 103–113, 1980.

Yagoda, H. P., “Centrifugally-Induced Stresses within Center-Wound Rolls-Part I,” Mechanics Research Communications, vol. 7, no. 3, pp. 181–193, 1980.

Hakiel, Z., “Nonlinear Model for Wound Roll Stress,” Tappi Journal, vol. 70, no. 5, pp. 113–117, 1987.

Lin, J. and Westmann, R., “Viscoelastic Winding Mechanics,” Journal of Applied Mechanics, vol. 56, no. 4, pp. 821–827, 1989.

Good, J. K., Wu, Z., and Fikes, M. W. R., “The Internal Stresses in Wound Rolls with the Presence of a Nip Roller,” Journal of Applied Mechanics, vol. 61, no. 1, pp. 182–185, 1994.

Benson, R., “A Nonlinear Wound Roll Model Allowing for Large Deformation,” Journal of Applied Mechanics, vol. 62, no. 4, pp. 853–859, 1995.

Burns, S., Meehan, R. R., and Lambropoulos, J., “Strain-Based Formulas for Stresses in Profiled Center-Wound Rolls,” Tappi Journal, vol. 82, no. 7, pp. 159–167, 1999.

Kabore, P., Jaafar, H., Wang, H., Hamad, W., and Wang, A., “Modelling Radial Compressive Modulus in Wound Rolls,” Measurement and Control, vol. 40, no. 7, pp. 207–210, 2007.

Liu, M., “A Nonlinear Model of Center-Wound Rolls Incorporating Refined Boundary Conditions,” Computers & Structures, vol. 87, Nos. 9–10, pp. 552–563, 2009.

Mollamahmutoglu, C. and Good, J., “Modeling the Influence of Web Thickness and Length Imperfections Resulting from Manufacturing Processes on Wound Roll Stresses,” CIRP Journal of Manufacturing Science and Technology, vol. 8, pp. 22–33, 2015.

Lee, J. and Lee, C., “An Advanced Model for the Numerical Analysis of the Radial Stress in Center-Wound Rolls,” International Journal of Mechanical Sciences, vol. 105, pp. 360–368, 2016.

Liu, Z., “Dynamic Analysis of Center-Driven Web Winder Controls,” Proc. of Industry Applications Conference, 1999. Thirty-Fourth IAS Annual Meeting. Conference Record of the 1999 IEEE, pp. 1388–1396, 1999.

Yagoda, H., “Centrifugally-Induced Stresses within Center-Wound Rolls-Part I,” Mechanics Research Communications, vol. 7, no. 3, pp. 181–193, 1980.

Kang, H. and Lee, C., “Effect of Tension on Conductivity of Gravure Printed Ag Layer in Roll-to-Roll Process,” International Journal of Precision Engineering and Manufacturing, vol. 16, no. 1, pp. 99–104, 2015.

Cho, S.-M., Kim, K. S., Lee, K.-M., Lee, S., Lee, Y.-J., and Lyu, S.-K., “A Study on Cycling Life and Failure Mode of Type3 Cylinder Treated with Autofrettage Pressure,” International Journal of Precision Engineering and Manufacturing, vol. 17, no. 12, pp. 1685–1691, 2016.

Lei, H., Cole, K., and Weinstein, S., “Modeling Air Entrainment and Temperature Effects in Winding,” Journal of Applied Mechanics, vol. 70, no. 6, pp. 902–914, 2003.

Boutaghou, Z.-E. and Chase, T. R., “Formulas for Generating Prescribed Residual Stress Distributions in Center-Wound Rolls,” Journal of Applied Mechanics, vol. 58, no. 3, pp. 836–840, 1991.

Veres, R. P. and Newton, J. O., “Control Techniques for Film and Fabric Winders,” IEEE Transactions on Industry Applications, Vol. IA-8, no. 3, pp. 240–247, 1972.

Vaidyanathan, N., “A Study on Wound Roll Slippage,” Oklahoma State University, 1996.

Kovil Kandadai, B., “Development of Wound-on-Tension in Webs Wound into Rolls,” Oklahoma State University, 2006.

Young, G. E. and Reid, K. N., “Lateral and Longitudinal Dynamic Behavior and Control of Moving Webs,” Journal of Dynamic Systems, Measurement, and Control, Vol. 115, No. 2B, pp. 309–317, 1993.

Roisum, D. R., “The Mechanics of Web Spreading. I,” Tappi Journal, vol. 76, no. 10, pp. 63–70, 1993.

Zhou, W., “Robust and Decentralized Control of Web Winding Systems,” Cleveland State University, 2007.

Kim, J., “Development of Hardware Simulator and Controller for Web Transport Process,” Journal of Manufacturing Science and Engineering, vol. 128, no. 1, pp. 378–381, 2006.

Shin, K., Park, J., and Lee, C., “A 250-mm-Width, Flexible, and Continuous Roll-to-Roll Slot-Die Coated Carbon Nanotube/Silver Nanowire Film Fabrication and a Study on the Effect of Anti-Reflective Overcoat,” Thin Solid Films, vol. 598, pp. 95–102, 2016.

Vedrines, M. and Knittel, D., “Modelling and H∞ Low Order Control of Web Handling Systems with a Pendulum Dancer,” IFAC Proceedings Volumes, vol. 41, no. 2, pp. 1012–1017, 2008.

Frechard, J., Knittel, D., Dessagne, P., Pellé, J., Gaudiot, G., et al., “Modelling and Fast Position Control of a New Unwinding-Winding Mechanism Design,” Mathematics and Computers in Simulation, vol. 90, pp. 116–131, 2013.

Kang, H.-K., Lee, C.-W., Shin, K.-H., and Kim, S.-C., “Modeling and Matching Design of a Tension Controller Using Pendulum Dancer in Roll-to-Roll Systems,” IEEE Transactions on Industry Applications, vol. 47, no. 4, pp. 1558–1566, 2011.

Choi, K.-H., Tran, T. T., and Kim, D.-S., “Back-Stepping Controller Based Web Tension Control for Roll-to-Roll Web Printed Electronics System,” Journal of Advanced Mechanical Design, Systems, and Manufacturing, vol. 5, no. 1, pp. 7–21, 2011.

Jo, W., Lee, B., and Kim, D., “Development of Auditory Feedback System for Violin Playing Robot,” International Journal of Precision Engineering and Manufacturing, vol. 17, no. 6, pp. 717–724, 2016.

Frechard, J. and Knittel, D., “Drive Requirements for Elastic Web Roll-to-Roll Systems,” Mechanism and Machine Theory, vol. 66, pp. 14–31, 2013.

Seshadri, A. and Pagilla, P.R., “Modeling and Control of a Rotating Turret Winder Used in Roll-to-Roll Manufacturing,” Control Engineering Practice, vol. 41, pp. 164–175, 2015.

Wolfermann, W., “Tension Control of Webs. A Review of the Problems and Solutions in the Present and Future,” Proc. of the 3rd International Conference on Web Handling, pp. 198–229, 1995.

Angermann, A., Aicher, M., and Schroder, D., “Time-Optimal Tension Control for Processing Plants with Continuous Moving Webs,” Proc. of Industry Applications Conference, 2000. Conference Record of the 2000 IEEE, pp. 3505–3511, IEEE, 2000.

Reid, K. N., Shin, K.-H., and Lin, K.-C., “Variable-Gain Control of Longitudinal Tension in a Web Transport System,” ASME Applied Mechanics Division-Publications-AMD, vol. 149, pp. 87–87, 1993.

Cheng, C.-W., Hsiao, C.-H., Chuang, C.-C., Chen, K.-C., and Tseng, W.-P., “Observer-Based Tension Feedback Control of Direct Drive Web Transport System,” Proc. of IEEE International Conference on Mechatronics, pp. 745–750, 2005.

Pagilla, P. R., Siraskar, N. B., and Dwivedula, R. V., “Decentralized Control of Web Processing Lines,” IEEE Transactions on Control Systems Technology, vol. 15, no. 1, pp. 106–117, 2007.

Raul, P. R., Manyam, S. G., Pagilla, P. R., and Darbha, S., “Output Regulation of Nonlinear Systems with Application to Roll-to-Roll Manufacturing Systems,” IEEE/ASME Transactions on Mechatronics, vol. 20, no. 3, pp. 1089–1098, 2015.

Koc, H., Knittel, D., de Mathelin, M., and Abba, G., “Modeling and Robust Control of Winding Systems for Elastic Webs,” IEEE Transactions on Control Systems Technology, vol. 10, no. 2, pp. 197–208, 2002.

Giannoccaro, N., Messina, A., and Sakamoto, T., “Updating of A Lumped Model for an Experimental Web Tension Control System Using a Multivariable Optimization Method,” Applied Mathematical Modelling, vol. 34, no. 3, pp. 671–683, 2010.

Nishida, T., Sakamoto, T., and Giannoccaro, N. I., “Self-Tuning Pi Control Using Adaptive PSO of a Web Transport System with Overlapping Decentralized Control,” Electrical Engineering in Japan, vol. 184, no. 1, pp. 56–65, 2013.

Giannoccaro, N. I., Nishida, T., and Sakamoto, T., “Decentralized Control Performances of an Experimental Web Handling System,” International Journal of Advanced Robotic Systems, Vol. 9, Paper No. 141, 2012.

Wu, S.-Y., “Determination of the Maximum Value of Recoiling Tension within a Rolling Pass,” Nonferrous Metals Processing, vol. 31, no. 1, pp. 54–62, 2002.

Hu, J., Jiang, Z., and Lu, H., “Research on Taper Tension Control Theory Apply in Material Rolling up Procedure,” in: Communications and Information Processing, Zhao, M., Sha, J., (Eds.), Springer, pp. 1–8, 2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, C. Stresses and Defects in Roll Products: A Review of Stress Models and Control Techniques. Int. J. Precis. Eng. Manuf. 19, 781–789 (2018). https://doi.org/10.1007/s12541-018-0094-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-018-0094-z