Abstract

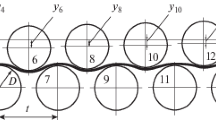

To ensure quality of the steel structures used in the shipbuilding and construction industry, the thick plate market increasingly demands for more flatness and higher residual stress. Diminishing slit camber caused by residual stress and incorrect flatness due to aging effect has recently emerged as important quality issues. In the current study, we proposed a new numerical model for a twodimensional roller leveler which calculates the curvature and moment of the material depending on the intermesh. This curvature was used to calculate the stress and strain values of the material along the thickness direction. Correction factors were also introduced to correct the location of the contact point that changes when the relationship between the intermesh and curvature was assumed as three-point bending of a concentrated load at the plate center. The result from this numerical model and that of the finite element analysis were compared to verify the effectiveness of this model.

Similar content being viewed by others

References

Soda, C., “A Study on Plate Leveling (1st Report),” J. Mech. Lab., Vol. 15, No. 4, pp. 310–348, 1961. (in Japanese)

Araki, J., “An Analysis of Longitudinal Profile of Material in Straightening,” Seisan-kenkyu (J. Inst. Indust. Sci., Univ. Tokyo), Vol. 24, No. 7, pp. 267–270, 1972. (in Japanese)

Matoba, T., Ataka, M., and Jimma, T., “Calculation Method of Roller Leveling Conditions for Steel Plates,” Journal of the Japan Society for Technology of Plasticity, Vol. 36, No. 418, pp. 1306–1311, 1995. (in Japanese)

Ye, H. and Hwang, S., “Prediction of the Residual Stress for a Steel Plate after Roller Leveling-Part I: Development of the Model,” Transactions of Materials Processing, Vol. 22, No. 1, pp. 5–10, 2013.

Park, K.-C. and Hwang, S.-M., “Development of a Finite Element Analysis Program for Roller Leveling and Application for Removing Blanking Bow Defects of Thin Steel Sheet,” ISIJ International, Vol. 42, No. 9, pp. 990–999, 2002.

Smith, R. P., “The Effect of the Number of Leveling Rolls on the Straightening Process,” Iron & Steel Technology, Vol. 4, No. 8, pp. 57–68, 2007.

Cai, Z.-Y., Li, L.-L., Wang, M., and Li, M.-Z., “Process Design and Longitudinal Deformation Prediction in Continuous Sheet Metal Roll Forming for Three-Dimensional Surface,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 9, pp. 1889–1895, 2014.

Hibino, F., “The Practical Formula for Leveling Strain in a Roller Leveler,” Journal of the Japan Society for Technology of Plasticity, Vol. 31, No. 349, pp. 208–212, 1990.

Lee, J.-B., Kwon, H.-C., and Lee, S.-J., “Research on Optimal Leveling Conditions of Roller Leveler in Thick Plate Mill,” Proc. of the Korean Society for Technology of Plasticity Conference, pp. 93–96, 2009.

Bathe, K. J., “Finite Element Procedures,” Prentice-Hall, 1996.

Vafaeesefat, A. and Khanahmadlu, M., “Comparison of the Numerical and Experimental Results of the Sheet Metal Flange Forming Based on Shell-Elements Types,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 5, pp. 857–863, 2011.

Liu, K., Liu, Y., and Yang, H., “Experimental and Fe Simulation Study on Cross-Section Distortion of Rectangular Tube under Multi-Die Constraints in Rotary Draw Bending Process,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 4, pp. 633–641, 2014.

Fang, G., Gao, W.-R., and Zhang, X.-G., “Finite Element Simulation and Experiment Verification of Rolling Forming for the Truck Wheel Rim,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 7, pp. 1509–1515, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, JB., Kang, SS. Numerical Modeling of Roller Leveler for Thick Plate Leveling. Int. J. Precis. Eng. Manuf. 19, 425–430 (2018). https://doi.org/10.1007/s12541-018-0051-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-018-0051-x