Abstract

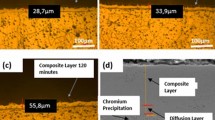

The paper describes results that were achieved by joining the ferritic stainless steel AISI 430 and the austenitic stainless steel AISI 314 by two-component metal injection molding. Sinterdilatometry was used to compare the sintering response of the materials. To compensate discrepancies in shrinkage during co-sintering, several gas-atomized powder fractions were combined. Using this approach, feedstock combinations which did not exceed a shrinkage mismatch of 5% were processed into micro tensile test specimens by sequential or simultaneous co-injection molding. The ferritic/austenitic interfaces were characterized with a focus on interdiffusion of alloying elements and mechanical properties. Defect-free and well-connected bi-material specimens with magnetic/non-magnetic properties were obtained. Results showed that the interdiffusion between the utilized steels resulted in a local strengthening effect that increased the hardness and mechanical properties of the interface. The tensile strength was comparable to the strength of the base material and all specimens failed outside the interface. It demonstrates that the investigated material combination is suitable to produce magnetic/non-magnetic parts by two-component metal injection molding.

Similar content being viewed by others

References

German, R. M. and Bose, A., “Injection Molding of Metals and Ceramics,” Metal Powder Industries Federation, pp. 12–13, 227–229, 1997.

Williams, B., “Powder Metallurgy -A Global Market Review,” International Powder Metallurgy Directory, 15th Ed., pp. 90–91, 2012.

Heaney, D. F., “Handbook of Metal Injection Molding,” Elsevier, pp. 32–34, 2012.

Pest, A., Petzoldt, F., Eifert, H., Veltl, G., Hartwig, T., and German, R. M., “Composite Parts by Powder Injection Molding,” Advances in Powder Metallurgy and Particulate Materials, Vol. 5, pp. 171–178, 1996.

Alcock, J., Logan, P., and Stephenson, D., “Metal Co-Injection Moulding,” Journal of Materials Science Letters, Vol. 15, No. 23, pp. 2033–2035, 1996.

Alcock, J., Logan, P., and Stephenson, D., “Surface Engineering by Co-Injection Moulding,” Surface and Coatings Technology, Vol. 105, No. 1, pp. 65–71, 1998.

Petzoldt, F., “Multifunctional Parts by Two-Component Powder Injection Moulding (2C-PIM),” Powder Injection Moulding International, Vol. 4, No. 1, pp. 21–27, 2010.

Johnson, J. L., Tan, L. K., Suri, P., and German, R. M., “Design Guidelines for Processing Bi-Material Components via Powder-Injection Molding,” JOM, Vol. 55, No. 10, pp. 30–34, 2003.

Johnson, J. L., Tan, L. K., Bollina, R., Suri, P. and German, R. M., “Bi-Metal Injection Molding of Tough/Wear-Resistant Components,” Advances in Powder Metallurgy and Particulate Materials, Part. 8, pp. 262–272, 2003. https://wwwcavsmsstateedu/publications/docs/ 2003/07/2003–24pdf (Accessed 19 JAN 2016)

Mulser, M., Baumann, A., Ebert, S., Imgrund, P., Langer, I., and Petzoldt, F., “Materials of High Hardness and Wear Resistance Joined to Stainless Steel by 2C-MIM,” Advances in Powder Metallurgy & Particulate Materials, pp. 140–148, 2014.

Imgrund, P., Rota, A., and Simchi, A., “Microinjection Moulding of 316L/17–4PH and 316L/Fe Powders for Fabrication of Magnetic-Nonmagnetic Bimetals,” Journal of Materials Processing Technology, Vol. 200, No. 1, pp. 259–264, 2008.

Barbosa, A. P. C., Bram, M., Stöver, D., and Buchkremer, H. P., “Realization of a Titanium Spinal Implant with a Gradient in Porosity by 2-Component-Metal Injection Moulding,” Advanced Engineering Materials, Vol. 15, No. 6, pp. 510–521, 2013.

Maetzig, M. and Walcher, H., “Assembly Moulding of MIM Materials,” Proc. of European Powder Metallurgy Congress and Exhibition, Vol. 2, pp. 43–48, 2006.

Heaney, D. F., Suri, P., and German, R. M., “Defect-Free Sintering of Two Material Powder Injection Molded Components -Part I: Experimental Investigations,” Journal of Materials Science, Vol. 38, No. 24, pp. 4869–4874, 2003.

German, R. M., Heaney, D. F., and Johnson, J. L., “Bi-Material Components using Powder Injection Molding: Densification, Shape Complexity, and Performance Attributes,” Advances in Powder Metallurgy and Particulate Materials, Vol. 4, pp. 41–52, 2005.

Simchi, A., Rota, A., and Imgrund, P., “An Investigation on the Sintering Behavior of 316L and 17–4PH Stainless Steel Powders for Graded Composites,” Materials Science and Engineering: A, Vol. 424, No. 1, pp. 282–289, 2006.

Simchi, A. and Petzoldt, F., “Cosintering of Powder Injection Molding Parts Made from Ultrafine WC-Co and 316L Stainless Steel Powders for Fabrication of Novel Composite Structures,” Metallurgical and Materials Transactions A, Vol. 41, No. 1, pp. 233–241, 2010.

Miura, H., Yano, T., and Matsuda, M., “PIM in-Process Joining for More Complicated Shape and Functionality,” Advances in Powder Metallurgy and Particulate Materials, Vol. 10, pp. 295–300, 2002.

Baumgartner, R. and Tan, L.-K., “Powder Injection Moulding of Bi-Metal Components,” Proc. of European Powder Metallurgy Congress and Exhibition, Vol. 3, pp. 135–140, 2001.

Ruh, A., Dieckmann, A.-M., Heldele, R., Piotter, V., Ruprecht, R., et al., “Production of Two-Material Micro-Assemblies by Two-Component Powder Injection Molding and Sinter-Joining,” Microsystem Technologies, Vol. 14, No. 12, pp. 1805–1811, 2008.

Schulze, G., “Die Metallurgie des Schweiβens,” Springer, 3rd Ed., p. 198, 2004.

German, R. M., “Powder Metallurgy Science,” Metal Powder Industries Federation, Princeton, 2nd Ed., p. 251, 1994.

Mulser, M., Petzoldt, F., Lipinski, M., and Hepp, E., “Influence of the Injection Parameters on the Interface Formation of Co-injected PIM Parts,” Proc. of European Powder Metallurgy Congress and Exhibition, Vol. 2, pp. 159–164, 2011.

Li, Y., He, H., Wang, G., and Deng, Z., “Effect of Delay Time on Material Distribution of Metal Co-injection Moulding,” Proc. of Powder Metallurgy World Congress and Exhibition, Vol. 4, pp. 511–517, 2010.

Olson, D. L., Siewert, T. A., Liu, S., and Edwards, G. R., “ASM Handbook: Welding, Brazing, and Soldering,” ASM International, Vol. 6, p. 223, 1993.

Kou, S., “Welding Metallurgy,” Wiley, 2nd Ed., p. 211, 2002.

Bargel, H.-J. and Schulze, G., “Werkstoffkunde,” Springer, 6th Ed., p. 182, 230, 1999.

Firouzdor, V., Simchi, A., and Kokabi, A. H., “An Investigation of the Densification and Microstructural Evolution of M2/316L Stepwise Graded Composite during Co-Sintering,” Journal of Materials Science, Vol. 43, No. 1, pp. 55–63, 2008.

Klar, E. and Samal, P. K., “Powder Metallurgy Stainless Steels: Processing, Microstructures, and Properties”, ASM International, pp. 127–128, 2007.

Metal Powder Industries Federation, “Materials Standards for Metal Injection Molded Parts,” http://wwwmimaweborg/std35mim_indiv. pdf (Accessed 29 JAN 2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mulser, M., Veltl, G. & Petzoldt, F. Development of magnetic/non-magnetic stainless steel parts produced by two-component metal injection molding. Int. J. Precis. Eng. Manuf. 17, 347–353 (2016). https://doi.org/10.1007/s12541-016-0043-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0043-7