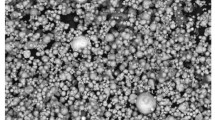

In the manufacture of sintered steels by metal injection molding (MIM), typical microstructural defects, such as pores and pore agglomerates, phase structure heterogeneities, and boundaries between different phases, are hard to avoid. Such heterogeneities cause crack origination, growth, and propagation when sintered materials are subjected to mechanical loads. The crack propagation path and fracture resistance are associated with the complex heterogeneous structure including ferrites, cementites, martensites, pores, and weak interfaces. With increasing sintering times, metal grains grow rapidly, leading to brittle fracture of the samples. Subsequent heat treatment substantially decreases the grain size and changes brittle fracture to ductile one. Multicycle sintering of the Catamold 8740 low-alloy steel greatly increases the impact strength of V-notched samples (from 7.55 to 13.95 J/cm2). Greater density of the samples and fewer stress concentrators favorably influence the material’s capability to withstand impact loads. Thus when density of the billets following six sintering cycles increases by 2.5%, their impact strength becomes 1.8 times higher. With a greater number of sintering cycles, the ductile dimples become significantly larger, while the increase in shock impact and density of the sintered material gradually slows down. The grain size substantially increases (in turn, suppressing pore healing) and density of the samples becomes greater over the total sintering time. X-ray diffraction and spectral analysis revealed additional phases after sintering and heat treatment. Additional fine-crystalline carbide and oxide phases become more distinguished with further increase in the sintering temperature and heat treatment. Brittle inclusions, along with residual porosity, present in sintered steel decrease the dynamic properties of the material.

Similar content being viewed by others

References

D.F. Heaney, Handbook of Metal Injection Molding, Wood Head Publishing (2012), p. 612.

Randall M. German, Injection Molding of Metals and Ceramics, Metal Powder Industry Federation (1997), p. 413.

S.V. Zavadyuk, P.I. Loboda, T.O. Solovyova, I.Yu. Trosnikova, and O.P. Karasevska, “Optimization of the sintering parameters for materials manufactured by powder injection molding,” Powder Metall. Met. Ceram., 59, No. 1–2, 22–28 (2020).

E. Dudrova and M. Kabatova, “Fractography of sintered iron and steels,” Powder Metall. Prog., 8, No. 2, 59–75 (2008).

O.M. Romaniv, Yu.V. Zima, and G.V. Karpenko, Electron Diffraction of Hardened Steels [in Ukrainian], Kyiv (1974), p. 208.

Fracture: Proceedings of International Conference on the Atomic Mechanisms of Fracture, Swampscott, Massachusetts (1959).

L.P. Gerasimova, A.A. Ezhov, and M.I. Maresev, Fractures of Structural Steels [in Russian], Moscow (1987), p. 272.

M.P. Braun, Fractography, Hardenability, and Properties of Alloys [in Russian], Kyiv (1966), p. 312.

J.A. Fellows, Fractography and Atlas of Fractographs: Metals Handbook, American Society for Metals, Metals Park, Ohio (1974).

GOST 9454–78. Metals. Bending Impact Test Methods at Reduced, Room, and Elevated Temperatures [in Russian], Izd. Standartov, Moscow (1979), p. 13.

D. Gaskell, Introduction to the Thermodynamics of Materials, 6th ed., Taylor & Francis Group, LLC, New York (2018), p. 687.

V.N. Antsiferov and T.G. Cherepanova, Structure of Sintered Steels [in Russian], Moscow (1981), p. 112.

S.A. Firstov and M. Slesar (eds.), Structure and Strength of Powder Materials [in Russian], Naukova Dumka, Kyiv (1995), p. 174.

GOST 5639–82. Steels and Alloys. Methods for Revealing and Determining the Grain Size [in Russian], Izd. Standartov, Moscow (1983), p. 21.

Randall M. German, Sintering: From Empirical Observations to Scientific Principles, Butterworth-Heinemann (2014), p. 544.

I. Chang and Y. Zhao, Advances in Powder Metallurgy, Woodhead Publishing Limited (2013), p. 604.

Acknowledgements

The research was conducted within State Budgetary Project No. 2306-f funded by the Ministry of Education and Science of Ukraine.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 11–12 (536), pp. 38–49, 2020.

Rights and permissions

About this article

Cite this article

Zavadiuk, S.V., Loboda, P.I., Soloviova, T.O. et al. Fracture Features of Low-Alloy Steel Produced by Metal Injection Molding. Powder Metall Met Ceram 59, 641–650 (2021). https://doi.org/10.1007/s11106-021-00199-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00199-0