Abstract

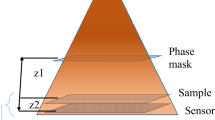

In Infra-Red (IR) microscopy, the improvement of spatial resolution is difficult due to the diffraction limit of IR objective. As one of solutions, a solid immersion lens (SIL) is incorporated into the conventional objective. The high refractive index of SIL contributes to obtain the high spatial resolution image of sample immersed in SIL. However, the alignment between the SIL and the objective is difficult by the narrow depth of focus and field of view. In addition, the distance between the SIL and a sample should be less than 100 nm. Therefore the mounting device specialized for mounting of the SIL should be needed. In our study, we designed the mounting device to achieve of the maximum optical performance of the SIL. Vertical flexibility of the mounting device relieves limit of the movement in vertical direction and the contact stress. The mechanical safety and motion of the mounting device with the SIL were analyzed using finite element analysis. To evaluate the imaging system overall, the SIL was incorporated into the IR imaging system using the mounting device. As a result, we achieved the spatial resolution of 1.23 μm using obtained images of USAF target.

Similar content being viewed by others

References

Galovic, S., Soskic, Z., and Todorovic, D. M., “Thermal Wave Microscopy: Fundamentals and Applications,” Microscopy: Science, Technology, Application and Education, Vol. 39, No. 12, pp. 1506–1515, 2010.

Breitenstein, O., Schmidt, C. and Karg, D., “Thermal Failure Analysis by IR Lock-in Thermograpy,” Microelectronics Failure Analysis Desk Reference, Sixth Edition, pp. 330–339, 2011.

Kino, G. S., “Applications and Theory of the Solid Immersion Lens,” Proc. of SPIE, Vol. 3609, pp. 56–66, 1999.

Breitenstein, O., Altmann, F., Riediger, T., Karg, D. and Gottschalk, V., “Lock-in Thermal IR Imaging using a Solid Immersion Lens,” Microelectron. Reliab., Vol. 46, No. 9-11, pp. 1508–1513, 2006.

Liu, L. and He, S., “Near-field Optical Storage System using a Solid Immersion Lens with a Left-handed Material Slab,” Opt. Express., Vol. 12, No. 20, pp. 4835–4840, 2004.

Birkbeck, A. L., Zlatanovic, S., Ozkan, M., and Esener, S. C., “Lazer Tweezer Controlled Solid Immersion Lens for High Resolution Imaging in Microfluidic and Biological Samples,” Proc. of SPIE, Vol. 5275, pp. 76–84, 2004.

Tanabe, H., Arata, I., and Terada, H., “Solid Immersion Lens Holder,” US Patent, No. 2005/0094293 A1, 2005.

Terada, H. and Tanabe, H., “Solid Immersion Lens Holder,” US Patent, No. 2010/0172035 A1, 2010.

Sung, H., Lee, M. S., Lee, G. J., Kim, K., Ryu, Y., and et. al., “Fabrication of Solid Immersion Lens Applied to Infrared Microscopy to Improve the Spatial Resolution over Its Diffraction Limit,” Proc. of SPIE, Vol. 8884, 2013.

Yoder, P. R., “Mounting Optics in Optical Instruments,” SPIE Optical Engineering Press, 2nd Ed., pp. 14–17, 2002.

Lee, D. G., Park, J. H., Park, K. H., Ha, B. K., Kim, H. S., and Park, S. H., “Investigation of the Frictional Impulse Induced Abnormal Noise in a Refrigerator,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 4, pp. 559–566, 2013.

Bea. J. H., Nath. S. D., and Kim, S. G., “Development of an Electric Performance Testing System for Ceramic Chips using a PZT Actuator,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 4, pp. 613–618, 2013.

Suzuki, H., Koshikawa, k., Kuroda, T., Ishizuka, T., Ji, W. J., and et. al., “Improvement of Performance for Higher Magnification Thermal Imaging,” Proc. of IEEE 16th International Symposium on the Physical and Failure Analysis of Integrated Circuits, pp. 489–492, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sung, HY., Lee, KS., Kim, HS. et al. Fabrication of mounting device to apply solid immersion lens to infra-red microscopy. Int. J. Precis. Eng. Manuf. 15, 375–379 (2014). https://doi.org/10.1007/s12541-014-0347-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0347-4