Abstract

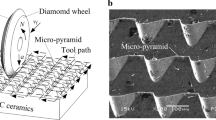

It is very difficult to evaluate 3D profile accuracy of micro-machined surface due to the 3D characterization of its measured point cloud. Hence, three ideal point cloud models, which are grid point model, slash profile model and horizontal profile model, were constructed to register 3D measured point cloud of micro-machined surface and evaluate the accuracies of characterized profile and points. First, #400 and #600 diamond wheel V-tips were employed to fabricate non-integrated and integrated micro-pyramid-structured surfaces with 173 µm in depth and 0.865 in aspect ratio in Computer Numerical Control (CNC) grinding system, respectively; then a white light interferometer was utilized to measure the micro-ground surfaces; finally, registration accuracy and registration efficiency were investigated with regard to characterized profile and point accuracies. The results show that registration accuracy increases and registration efficiency decreases with increasing model point number, but they have little relation with the posture of measured point cloud. Registration error may converge to micro-ground form error when model point number is larger than measured point number. Moreover, the slash profile and horizontal profile models may register characterized profile and point more precisely than grid point model. The slash profile model can produce the best registration accuracy and efficiency. It is confirmed that the micro-ground form errors are 23.8 µm and 7.9 µm, the characterized profile errors are 37.2 µm and 19.0 µm and the characterized peak errors are 51.2 µm and 34.1 µm for non-integrated surface and integrated surface, respectively. As a result, a #600 diamond grinding wheel may be used to perform a precision micro-grinding in CNC grinding system.

Similar content being viewed by others

References

Kolesar, E. S., Bright, V. M., and Sowders, D. M., “Optical reflectance reduction of textured silicon surfaces coated with an antireflective thin film,” Thin Solid Films, Vol. 290–291, pp. 23–29, 1996.

Ohwada, K., Negoro, Y., Konaka, Y., and Oguchi, T., “Uniform groove-depths in (110) Si anisotropic etching by ultrasonic waves and application to accelerometer fabrication,” Sensors and Actuators A: Physical, Vol. 50, No. 1–2, pp. 93–98, 1995.

Hayase, M., Kawase, T., and Hatsuzawa, T., “Miniature 250 µm thick fuel cell with monoithically fabricated silicon electrodes,” Electrochemical and Solid-State Letters, Vol. 7, No. 8, pp. A231–A234, 2004.

Hamzah, A. A., Aziz, N. A., Majlis, B. Y., Yunas, J., Dee, C. F., and Bais, B., “Optimization of HNA etching parameters to produce high aspect ratio solid silicon microneedles,” Journal of Micromechanics and Microengineering, Vol. 22, Paper No. 095017, 2012.

Xie, J., Zhuo, Y. W., and Tan, T. W., “Experimental study on fabrication and evaluation of micro pyramid-structured silicon surface using a V-tip of diamond grinding wheel,” Precision Engineering, Vol. 35, No. 1, pp. 173–182, 2011.

Lee, K. W., Noh, Y. J., Gao, W., Arai, Y., Shimizu, Y., Tanaka, K., Fukuta, M., and Kai, Y., “Experimental Investigation of an Airbearing Displacement Sensor for On-machine Surface Form Measurement of Micro-structures,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 4, pp. 671–678, 2011.

Butler-Smith, P. W., Axinte, D. A., and Daine, M., “Solid diamond micro-grinding tools: From innovative design and fabrication to preliminary performance evaluation in Ti-6Al-4V,” International Journal of Machine Tools and Manufacture, Vol. 59, pp. 55–64, 2012.

Xie, J., Xu, J., Tang, Y., and Tamaki, J., “3D graphical evaluation of micron-scale protrusion topography of diamond grinding wheel,” International Journal of Machine Tools and Manufacture, Vol. 48, No. 11, pp. 1254–1260, 2008.

Brinksmeier, E., Riemer, O., and Twardy, S., “Tribological behavior of micro structured surfaces for micro forming tools,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 4, pp. 425–430, 2010.

Dong, C. S., Gu, Y., Zhong, M. L., Li, L., Sezer, K., Ma, M. X., and Liu, W. J., “Fabrication of superhydrophobic Cu surfaces with tunable regular micro and random nano-scale structures by hybrid laser texture and chemical etching,” Journal of Materials Processing Technology, Vol. 211, No. 7, pp. 1234–1240, 2011.

Abdel-Aal, H. A., Mansori, M. E., and Mezghani, S., “Multi-Scale Investigation of Surface Topography of Ball Python (Python regius) Shed Skin in Comparison to Human Skin,” Tribology Letters, Vol. 37, No. 3, pp. 517–527, 2010.

Xie, J., Wei, F., Zheng, J. H., Tamaki, J., and Kubo, A., “3D laser investigation on micron-scale grain protrusion topography of truncated diamond grinding wheel for precision grinding performance,” International Journal of Machine Tools and Manufacture, Vol. 51, No. 5, pp. 411–419, 2011.

Xie, J., Luo, M. J., He, J. L., Liu, X. R., and Tan, T. W., “Microgrinding of Micro-groove Array on Tool Rake Surface for Dry Cutting of Titanium Alloy,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 10, pp. 1845–1852, 2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, J., Lu, YX., Liu, XR. et al. Study on 3D characterized profile and point accuracies of ground micro-pyramid-structured Si surface. Int. J. Precis. Eng. Manuf. 14, 627–634 (2013). https://doi.org/10.1007/s12541-013-0084-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0084-0