Abstract

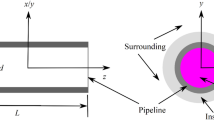

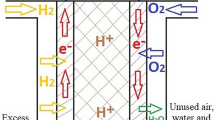

Improving the efficiency of the manufacturing process is one of the ways to resolve the ecological issues, cost-saving pressure, and new environmental legislations. This paper presents the study on the in-line induction heating process prior to hot forging of an automotive crankshaft in order to find the potential solutions for improving the energy efficiency. The heating strategy that divides the induction heating line into groups for flexible control and saving operating energy was introduced. Optimization of the operating parameters of the induction heating system, including voltages and frequencies, was done using design of experiment in conjunction with numerical simulation, approximation, and genetic algorithm optimization techniques. In addition, thermal insulation was proposed to reduce the heat losses. The research results show that the energy can be saved through process parameter optimization approximately 6%. Furthermore, if the insulating covers at the open spaces between adjacent heaters are used, roughly 4% of additional amount of the energy consumption can be reduced.

Similar content being viewed by others

References

Kang, Y.-C., Chun, D.-M., Jun, Y., and Ahn, S.-H., “Computeraided environmental design system for the energy-using product (EuP) directive,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 3, pp. 397–406, 2010.

Chryssolouris, G., Papakostas, N., and Mavrikios, D., “A perspective on manufacturing strategy: Produce more with less,” CIRP Journal of Manufacturing, Vol. 1, No. 1, pp. 45–52, 2008.

Herrmann, C., Thiede, S., Kara, S., and Hesselbach, J., “Energy oriented simulation of manufacturing systems — Concept and application,” CIRP Annals — Manufacturing Technology, Vol. 60, No. 1, pp. 45–48, 2011.

Park, C. W., Kwon, K. S., Kim, W. B., Min, B. K., Park, S. J., Sung, I. H., Yoon, Y., Lee, K. S., Lee, J. H., and Seok, J. W., “Energy consumption reduction technology in manufacturing — A selective review of policies, standards, and research,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 5, pp. 151–173, 2009.

Levacher, L., Hita, I., Bethenod, C., and Hartmann, S., “Energy efficiency in industry: from existing technologies to innovative solutions,” ECEEE 2009 Summer Study, pp. 1091–1100, 2009.

Wrona, E. and Nacke, B., “Rational use of energy in induction heaters for forging industry,” Proc. of International Scientific Colloquium, Modelling for saving resources, pp. 153–157, 2001.

Paya, B., “Investigation on energy recovering in an induction coil for continuous through heating billet,” XVI International congress on Electricity applications in modern world, UIE’08, 2008.

Favennec, Y., Labbé, V., and Bay, F., “Induction heating processes optimization a general optimal control approach,” Journal of Computational Physics, Vol. 187, No. 1, pp. 68–94, 2003.

Bodart, O., Boureau, A.-V., and Touzani, R., “Numerical investigation of optimal control of induction heating processes,” Applied Mathematical Modelling, Vol. 25, No. 8, pp. 697–712, 2001.

Galunin, S., Zlobina, M., Nikanorov, A., and Blinov, Y., “Numerical optimization of induction through heating for forging,” Proc. of the 9th Russian-Korean Int. Symp. on Science and Technology, pp. 313–314, 2005.

Pleshivtseva, Y., Rapoport, E., Efimov, A., Nacke, B., and Nikanorov, A., “Special method of parametric optimization of induction heating systems,” Proc. of International Scienticfic Colloqium, Modelling for Electromagnetic Processing, pp. 229–234, 2008.

Rapoport, E. and Pleshivtseva, Y., “Optimal Control of Induction Heating Processes,” CRC Press, pp. 273–281, 2006.

Rudnev, V. I., Loveless, D., Schweigert, K., Dickson, P., and Rugg, M., “Efficiency and Temperature Considerations in Induction Re-Heating of Bar, Rod and Slab,” Industrial Heating, pp. 39–43, 2000.

Zgraja, J., “The optimisation of induction heating system based on multiquadric function approximation,” The International Journal for Computation and Mathematics in Electrical and Electronic Engineering, Vol. 24, No. 1, pp. 305–313, 2005.

Rudnev, V., Brown, D., Tyne, C. J. V., and Clarke, K. D., “Intricacies for the Successful Induction Heating of Steels in Modern Forge Shops,” Proc. of 19th International Forging Congress, 2008.

Nemkov, V. S. and Goldstein, R. C., “Computer Simulation of Induction Heating Processes,” HeatTreating 2000: Proc. of the 20th ASM International Conference, pp. 882–888, 2000.

Sadeghipour, K., Dopkin, J. A., and Li, K., “A computer aided finite element/experimental analysis of induction heating process of steel,” Computers in Industry, Vol. 28, No. 3, pp. 195–205, 2096.

Tavakoli, M. H., Karbaschi, H., and Samavat, F., “Influence of workpiece height on the induction heating process,” Mathematical and Computer Modelling, Vol. 54, No. 1–2, pp. 50–58, 2011.

De Coster, J., Deliege, G., Henrotte, F., Pahner, U., Fransen, J., Van Dommelen, D., and Hameyer, K., “Design of a foil-coiled inductor for the heating of steel wires,” Proc. of the 4th International Conference on Computation in Electromagnetics, 2002.

Gür, C. H. and Pan, J., “Handbook of Thermal Process Modeling of Steels,” CRC Press, pp. 427–448, 2009.

Haimbaugh, R. E., “Practical Induction Heat Treating,” ASM International, pp. 19–42, 2001.

Pleshivtseva, Y., Rapoport, E., Efimov, A., Nacke, B., Nikanorov, A., Galunin, S., and Blinov, Y., “Potentials of Optimal Control Techniques in Induction Through Heating for Forging,” Proc. of International Scientific Colloquium, Modelling for Electromagnetic Processing, pp. 145–150, 2003.

Bay, F., Labbe, V., Favennec, Y., and Chenot, J. L., “A numerical model for induction heating processes coupling electromagnetism and thermomechanics,” Int. J. Numer. Meth. Engng., Vol. 58, No. 6, pp. 839–867, 2003.

Rudnev, V. I., Loveless, D., Cook, R., and Black, M., “Handbook of Induction Heating,” CRC Press, pp. 150–157, 2002.

Park, H. S. and Dang, X. P., “Structural optimization based on CAD-CAE integration and metamodeling techniques,” Computer-Aided Design, Vol. 42, No. 10, pp. 889–902, 2010.

Gauchia, A., Diaz, V., Boada, M. J. L., and Boada, B. L., “Torsional stiffness and weight optimization of a real bus structure,” International Journal of Automotive Technology, Vol. 11, No. 1, pp. 41–47, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, HS., Dang, XP. Optimization of the in-line induction heating process for hot forging in terms of saving operating energy. Int. J. Precis. Eng. Manuf. 13, 1085–1093 (2012). https://doi.org/10.1007/s12541-012-0142-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0142-z