Abstract

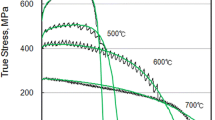

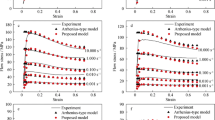

In this study, to achieve constitutive equations of Ti-6Al-4V alloy sheet, uni-axial tensile tests of Ti-6Al-4V alloy sheet with thickness of 1.0mm were performed at elevated temperature of 400°C ∼ 700°C. Equations of stress-strain curves are established for Ti-6Al-4V alloy sheet at elevated temperatures describing both work-hardening and softening stage of Ti-6Al-4V alloy sheet. Least square fitting method is used to determine material parameters. The parameters of fitting curves are utilized to determine them as a function of temperature using polynomial models. New mathematical models are used to calculate and predict the stress-strain curves at elevated temperatures. The calculated flow stress curves are in good agreement with experimental data and shown better than that of previous equation.

Similar content being viewed by others

References

Donachie, M. J., “Titanium: A Technical Guide,” ASM International, 2000.

Vafaeesefat, A. and Khanahmadlu, M., “Comparison of the numerical and experimental results of the sheet metal flange forming based on shell-elements types,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 5, pp. 857–863, 2011.

Seong, D. Y., Jung, C. G., Yang, D. Y. and Chung, W. J., “Efficient prediction of local failures for metallic sandwich plates with pyramidal truss cores during the bending processes,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 3, pp. 491–503, 2011.

Lin, Y. C., Chen, M. S. and Zhong, J., “Microstructural evolution in 42CrMo steel during compression at elevated temperatures,” Mater. Lett., Vol. 62, No. 14, pp. 2132–2135, 2008.

Takuda, H., Morishita, T. and Kinoshita, T., “Modelling of formula for flow stress of a magnesium alloy AZ31 sheet at elevated temperatures,” J. Mater. Processing Technol., Vol. 164–165, pp. 1258–1262, 2005.

Yang, Y. Q., Li, B. C. and Zhang, Z. M., “Flow stress of wrought magnesium alloys during hot compression deformation at medium and high temperatures,” Mater. Sci. Eng. A, Vol. 499, No. 1–2, pp. 238–241, 2009.

Zheng, Q. G., Ying, T. and Jie, Z., “Dynamic softening behaviour of AZ80 magnesium alloy during upsetting at different temperatures and strain rates,” Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf., Vol. 224, No. 11, pp. 1707–1716, 2010.

Nguyen, D. T., Banh, T. L., Jung, D. W., Yang, S. H. and Kim, Y. S., “A Modified Johnson-Cook Model to Predict Stress-Strain Curves of Boron Steel Sheets at Elevated and Cooling Temperatures,” High Temp. Mat. Proc., Vol. 31, No. 1, pp. 37–46, 2012.

Swift, H. W., “Plastic instability under plane stress,” J. Mech. Phys. Solids, Vol. 1, No. 1, pp. 1–18, 1952.

Voce, E., “The relationship between stress and strain for homogeneous deformation,” J. Inst. Met., Vol. 74, pp. 537–562, 1978.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nguyen, DT., Kim, YS. & Jung, DW. Flow stress equations of Ti-6Al-4V titanium alloy sheet at elevated temperatures. Int. J. Precis. Eng. Manuf. 13, 747–751 (2012). https://doi.org/10.1007/s12541-012-0097-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0097-0