Abstract

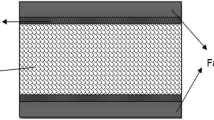

Objective of this study was to develop basic techniques in order to apply aluminum sandwich sheets for an automotive hood part. The aluminum sandwich sheet is the material fabricated by adhering two aluminum skins to one polypropylene core. When it has the same bending stiffness as a steel sheet, it is 65% lighter than the steel sheet and 30% lighter than an aluminum alloy sheet. Therefore, it is notified exclusively as good substitutive materials for a steel body to improve the fuel efficiency. Through aluminum sandwich sheet, however, it has relatively lower formability than that of the steel sheet for automotive application. In this study, we developed application techniques of the aluminum sandwich sheet for automotive hood. The various formability evaluations were carried out in order to secure the fundamental data for the measurement of sheet metal forming and the establishment of optimum application conditions of the sandwich sheet. From these results, it was found that the sandwich sheet could reduce the weight and maintain the flexural rigidity simultaneously comparing to the steel sheet.

Similar content being viewed by others

References

Veenstra, E. W., “Aluminum-Plastic-Aluminum Sandwich Sheet for Maximum Weight Reduction in Body Panels,” SAE Paper No. 930706, pp. 1–11, 1998.

Shin, K. S., Kim, K. J., Choi, S. W. and Rhee, M. H., “Mechanical Properties of Aluminum/Polypropylene/Aluminum Sandwich Sheets,” Metals and Materials International, Vol. 5, No. 6, pp. 613–618, 1999.

Kim, K. J., Kim, D., Choi, S. H., Chung, K., Shin, K. S., Barlat, F., Oh, K. H. and Youn, J. R., “Formability of AA5182/Polypropylene/AA5182 Sandwich Sheets,” J. of Materials Proc. Tech., Vol. 139, No. 1–3, pp. 1–7, 2003.

Kim, K. J., “Plastic Strain Ratios and Planar Anisotropy of AA5182/Polypropylene/AA5182 Sandwich Sheets,” Inter. J. of Auto. Tech., Vol. 6, No. 3, pp. 259–268, 2005.

Hill, R., “Mathematical Theory of Plasticity,” Oxford at the Clarendon Press, pp. 317–334, 1950.

Hosford, W. F., “Metal Forming-Mechanics and Metallurgy-2nd Edition,” Prentice Hall, pp. 270–282, 1993.

Kim, K. J, Sung, C. W., Baik, Y. N., Lee, Y. H., Bae, D. S., Kim, K.-H. and Won, S.-T., “Hydroforming Simulation of High-strength Steel Cross-members in an Automotive Rear Subframe,” IJPEM, Vol. 9, No. 3, pp. 55–58, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, K.J., Rhee, M.H., Choi, BI. et al. Development of application technique of aluminum sandwich sheets for automotive hood. Int. J. Precis. Eng. Manuf. 10, 71–75 (2009). https://doi.org/10.1007/s12541-009-0073-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-009-0073-5