Abstract

Three-dimensional (3D), cone-shape embossed aluminum sheets are used in automotive exhaust systems to increase their heat dissipation efficiency by increasing the surface area. However, the manufacturing process has various restrictions because wrinkling occurs easily during the press forming process. In this study, A tensile test and a bending test were performed to investigate the mechanical properties and springback characteristics of 3D aluminum sheets. We clarified how the direction in which the specimen is cut affects the tensile properties. The results of the tensile test showed that the characteristics of the parallel and diagonal direction specimens differed from each other and those of the as-received flat sheet. The 3D aluminum sheets had a smaller Young’s modulus and smaller flow stress than the as-received flat sheets in the small plastic range due to the flattening effect of the embossed cone shapes. However, as the plastic strain increased, the flow stress followed the as-received flat specimen’s flow stress curve because the cone-shape was flattened according to increases in the plastic strain. The yield stress increased in the diagonal-direction specimen and decreased in the parallel-direction specimen. The change in Young’s modulus in the 3D sheets affected the amount of springback.

Similar content being viewed by others

Abbreviations

- R1 :

-

the radius of the upper punch for the V-bending test

- R2 :

-

the radius of the lower die for the V-bending test

- L1 :

-

the distance between the upper die and the lower die for the V-bending test

- θi :

-

the initial angle of the specimen after the V-bending test

- θf :

-

the final angle of the specimen after the V-bending test

- Δθ:

-

the difference in the angle between the initial and final angles of the specimen after V-bending

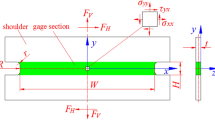

- R3 :

-

the radius of the upper punch for the U-draw bending test

- R4 :

-

the radius of the lower die for the U-draw bending test

- P1 :

-

the length of the punch for the U-draw bending test

- L2 :

-

the clearance of the die on the U-draw bending test

- θ1 :

-

the angle of the specimen on the upper punch shoulder

- θ2 :

-

the angle of the specimen on the lower die shoulder

- σY :

-

yield strength

- σTS :

-

tensile strength

- E:

-

Young’s modulus

- n:

-

strain hardening exponent

- K:

-

strength coefficient

- R:

-

plastic anisotropic coefficient

- dεwidth, dεthickness :

-

the plastic strain in the direction of the width and thickness, respectively

References

Kim, Y. S., Kim, K. S., and Kwon, N. C., “Press Formabilities of Aluminum Sheets for Autobody Application,” Proc. of the KSAE Conference, pp. 233–246, 1993.

Kim, Y. S., “Evaluation Apparatus and Method for Insulation Efficiency of the Heat Protector of the Automobile,” KR Patent, No. 10-1004202, 2010.

ArcelorMittal, “Steels Coated with Alusi® Aluminum-Silicon Alloy: Specific Applications,” http://automotive.arcelormittal.com/europe/products/alusi/alusi_specific_applications/EN (Accessed 23 MAR 2016).

Noh, H.-G., An, W.-J., Song, W.-J., Kang, B.-S., and Kim, J., “Experimental and Numerical Study on Patterned Emboss Forming using Electromagnetic Forces,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 7, pp. 1447–1454, 2015.

Namoco, Jr, C. S., Iizuka, T., Narita, K., Takakura, N., and Yamaguchi, K., “Effects of Embossing and Restoration Process on the Deep Drawability of Aluminum Alloy Sheets,” Journal of Materials Processing Technology, Vols. 187–188, pp. 202–206, 2007.

Namoco, Jr, C. S., Iizuka, T., Hatanaka, N., Takakura, N., and Yamaguchi, K., “Influence of Embossing and Restoration on the Mechanical Properties of Aluminum Alloy Sheets,” Journal of Materials Processing Technology, Vols. 192–193, pp. 18–26, 2007.

Fritzsche, S., Ossenbrink, R., and Michailov, V., “Experimental Characterisation of Structured Sheet Metal,” Key Engineering Materials, Vol. 473, pp. 404–411, 2011.

Cho, J. H., Choi, W. H., and Park, J. S., “Evaluation on the Mechanical Properties for Two Layer Composite Panel of 1xxx Series Aluminum,” Proc. of KSAE Conference, pp. 528–533, 2014.

Kim, M. K., “Mold Structure and Heat Protector for Heat Insulation of Automobile,” KR Patent, No. 10-2005-0042370, 2006.

Güler, H. and Özcan, R., “Effects of the Rotary Embossing Process on Mechanical Properties in Aluminum Alloy 1050 Sheet,” Metals and Materials International, Vol. 18, No. 2, pp. 225–230, 2012.

Abe, T., Yasota, T., Nonaka, Y., Saka, S., and Kuwabara, T., “Forming Simulation of Emboss Formation by Roll Forming,” Proc. of Japanese Spring Conference for the Technology of Plasticity, pp. 253–254, 2008.

Lee, S. W., “Prediction of Springback of DP590 Steel Sheets using Yoshida-Uemori Kinematic Hardening Model,” M.Sc. Thesis, Kyungpook National University, 2012.

Choi, J. G., Choi, S. C., Lee, M. G., and Kim, H. Y., “Measurement of Springback of AZ31B Mg Alloy Sheet in OSU Draw/Bend Test,” Transactions of Materials Processing, Vol. 16, No. 6, pp. 447–451, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oh, SH., Ahn, DC. & Kim, YS. A study on the mechanical properties and springback of 3D aluminum sheets. Int. J. Precis. Eng. Manuf. 17, 671–677 (2016). https://doi.org/10.1007/s12541-016-0082-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0082-0