Abstract

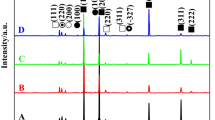

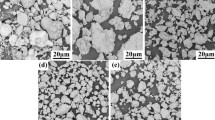

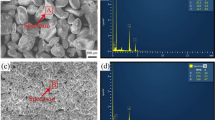

In the current work, the microstructure evolution and mechanical properties of (Ce + Yb) modified in situ TiB2/Al-Si matrix composite were systematically investigated by thermal deformation at strain rates of 0.0005–0.0125 s− 1 and temperatures of 250–450 °C. The enhanced strength and plasticity of the composite have a good correlation with the microstructure evolution under different thermal deformation parameters. The obtained results indicated that under the hot deformation parameters of strain rate of 0.0025 s− 1 and deformation temperature of 250 °C, the defects of micropores can be reduced or even eliminated and improved the density of the composite. The coarse α-Al grains, eutectic Si and Fe-rich phases and undissolved primary (Ce + Yb)-containing intermetallics were significantly refined under high shear stress. At the same time, the distribution of in-situ synthesized submicron TiB2 particles in the Al matrix tends to be more uniform. The substructures such as high density dislocations and low angle grain boundaries were introduced under the thermal deformation of 250 °C/0.0025 s− 1, which provided the necessary conditions for the formation of recrystallized grains that are less likely to overgrow and further promoted the aging precipitation of nano-strengthening precipitates. Finally, the UTS, YS and elongation of the composite reached the maximum values of 385 MPa, 316 MPa and 9.6% respectively, which were 60.4%, 85.9% and 45.5% higher than the as-cast and undeformed composite.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

O. Gursoy, G. Timelli, J. Mater. Res. Technol. 9, 8652 (2020). https://doi.org/10.1016/j.jmrt.2020.05.105

B. Li, H. Wang, J. Jie, Z. Wei, Mater. Des. 32, 1617 (2011). https://doi.org/10.1016/j.matdes.2010.08.040

M.G. Mahmoud, Y. Zedan, V. Songmene, A.M. Samuel, F.H. Samuel, Int. J. Metalcast. 16, 535 (2022). https://doi.org/10.1007/s40962-021-00640-5

Z. Hu, H. Yan, Y.S. Rao, Trans. Nonferrous Metal. Soc 23, 3228 (2013). https://doi.org/10.1016/S1003-6326(13)62857-5

Q. Li, Y. Zhu, S. Zhao, Y. Lan, D. Liu, G. Jian, Q. Zhang, H. Zhou, Intermetallics 120, 106768 (2020). https://doi.org/10.1016/j.intermet.2020.106768

Q. Zheng, L. Zhang, H. Jiang, J. Zhao, J. He, J. Mater. Sci. Technol. 47, 142 (2020). https://doi.org/10.1016/j.jmst.2019.12.021

Y. Yang, S.Y. Zhong, Z. Chen, M. Wang, N. Ma, H. Wang, J. Alloy. Compd. 647, 63 (2015). https://doi.org/10.1016/j.jallcom.2015.05.167

X. Li, C. Xia, Y. Wu, D. Chen, M. Wang, N. Ma, H. Wang, Mater. Sci-Medzg 25, 376 (2019). https://doi.org/10.5755/j01.ms.25.4.19453

F. Mao, G. Yan, Z. Xuan, Z. Cao, T. Wang, J. Alloy. Compd. 650, 896 (2015). https://doi.org/10.1016/j.jallcom.2015.06.266

S.C. Zhang, J.F. Leng, C.X. Li, X.Y. Teng, Mater. Sci. Forum 898, 259 (2017). https://doi.org/10.4028/www.scientific.net/MSF.898.259

G. Niu, J. Mao, J. Wang, Metall. Mater. Trans. A 50, 5935 (2019). https://doi.org/10.1007/s11661-019-05458-9

X. Song, H. Yan, X. Zhang, J. Rare Earth. 35, 412 (2017). https://doi.org/10.1016/S1002-0721(17)60927-x

Y. Zou, H. Yan, Z. Hu, Q. Ran, Mater. Res. Express 7, 026526 (2020). https://doi.org/10.1088/2053-1591/ab6fa7

X. Song, H. Yan, Q. Wu, Z. Hu, Int. J. Cast. Metal Res. 32, 59 (2019). https://doi.org/10.1080/13640461.2018.1518744

Y. Rao, H. Yan, Z. Hu, M. Fang, L. Zhang, Int. J. Metalcast. 16, 2210 (2022). https://doi.org/10.1007/s40962-021-00735-z

M. Qiu, S. Wang, X. Lei, P. Zhuang, X. Du, Int. J. Metalcast. 16, 1206 (2022). https://doi.org/10.1007/s40962-021-00673-w

S.L. Pramod, A.K.P. Ravikirana, B.S. Rao, S.R. Murty, Bakshi, Mater. Sci. Eng. A 739, 383 (2019). https://doi.org/10.1016/j.jallcom.2017.10.021

R. Tao, Y. Zhao, X. Kai, Y. Wang, W. Qian, Y. Yang, M. Wang, W. Xu, J. Alloy. Compd. 731, 200 (2018). https://doi.org/10.1016/j.jallcom.2017.10.021

W. Qian, Y. Zhao, X. Kai, Y. Yan, R. Tao, X. Gao, J. Alloy. Compd. 813, 152198 (2020).https://doi.org/10.1016/j.jallcom.2019.152198

M. Qiu, H. Liu, Z. Zhang, W. Hu, X. Du, Int. J. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00898-3

M. Qiu, X. Du, Z. Zhang, C. Chen, X. Lei, J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-022-07334-x

Z. Wei, Y. Lei, H. Yan, X. Xu, J. He, J. Rare Earth. 37, 659 (2019). https://doi.org/10.1016/j.jre.2018.11.008

X. Kai, Y. Zhao, A. Wang, C. Wang, Z. Mao, Compos. Sci. Technol. 116, 1 (2015). https://doi.org/10.1016/j.compscitech.2015.05.006

H. Ghandvar, M.H. Idris, N. Ahmad, J. Alloy. Compd. 751, 370 (2018). https://doi.org/10.1016/j.jallcom.2018.04.131

Y.S. Lee, J.K. Jung, S.B. Kim, S.H. Kim, C.Y. Lim, H.W. Kim, W.K. Kim, S.K. Hyun, Mater. Charact. 178, 111256 (2021). https://doi.org/10.1016/j.matchar.2021.111256

D. Ke, L. Hengcheng, J. Qiumin, T. Yun, Mater. Sci. Eng. A 527, 6887 (2010). https://doi.org/10.1016/j.msea.2010.07.068

P. Jin, B. Xiao, Q. Wang, Z. Ma, Y. Liu, S. Li, J. Mater. Sci. Technol. 27, 518 (2011). https://doi.org/10.1016/S1005-0302(11)60101-1

Z. Wang, Q. Zhang, L. Fu, P. Shao, Y. Zhou, P. Zhu, H. Su, G. Wu, J. Alloy. Compd.927, 167118 (2022).https://doi.org/10.1016/j.jallcom.2022.167118

X. Xu, W. Zhu, X. Guo, C. Liang, Y. Deng, J. Alloy. Compd. 935, 167892 (2023). https://doi.org/10.1016/j.jallcom.2022.167892

K. Yoshida, T. Ishizaka, M. Kuroda, S. Ikawa, Acta Mater. 55, 4499 (2007). https://doi.org/10.1016/j.actamat.2007.04.014

W. Wu, Z. Liu, Y. Hu, F. Li, S. Bai, P. Xia, A. Wang, C. Ye, J. Alloy. Compd. 730, 318 (2018). https://doi.org/10.1016/j.jallcom.2017.09.320

S. de La Chapelle, Scripta Mater. 45, 1387 (2001). https://doi.org/10.1016/S1359-6462(01)01174-5

Z. Hu, X. Li, J. Xi, L. Da, J. Alloy. Compd. 911, 165055 (2022). https://doi.org/10.1016/j.jallcom.2022.165055

A. Kazemi-Navaee, R. Jamaati, H.J. Aval, Mater. Sci. Eng. A 824, 141801 (2021). https://doi.org/10.1016/j.msea.2021.141801

Y. Wang, Y. Li, W. Yu, H. Tang, H. Wang, G. Xu, Z. Wang, J. Alloy. Compd. 935, 168072 (2023). https://doi.org/10.1016/j.jallcom.2022.168072

Acknowledgements

The authors acknowledge the financial support of the Science and Technology Agency of Anhui Province (202104a05020047 and 2022a05020032), the Industrial Guiding Fund of Changfeng County and Hefei University of Technology (JZ2019QTXM0281), the Intelligent Manufacturing Institute of HFUT (IMICZ2019003) and the Fundamental Research Funds for the Central Universities (PA2020GDGP0054).

Author information

Authors and Affiliations

Contributions

MQ: Conceptualization, data curation, methodology, validation, writing–original draft, preparation. WH: Methodology, validation. HL: Software, visualization. YP: Investigation, formal analysis. XD: Writing–review and editing, funding acquisition, project administration, resources, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiu, M., Hu, W., Liu, H. et al. Mechanical Properties of (Ce + Yb) Modified in situ TiB2/Al-Si Matrix Composites Enhanced via Thermal Deformation Combined with Heat Treatment. Met. Mater. Int. 29, 3078–3092 (2023). https://doi.org/10.1007/s12540-023-01425-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01425-7