Abstract

Nb-based alloys are regarded as a vital high temperature structural material. Unfortunately, the low oxidation resistance of the alloys limits their application under aerobic conditions at high temperature. Surface coating technology is considered to be an ideal method to solve this problem. This paper reviewed recent progress on silicide coatings on Nb and Nb-based alloy, and focused on different types of modification techniques. The microstructure, phase composition and oxidation properties of various silicified coatings are analyzed. The effects of modified elements and second phase on the oxidation mechanism of silicide coatings are also summarized. Finally, the existing problems and future development direction of various silicide coatings are pointed out.

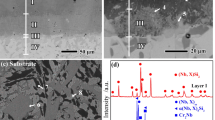

Graphical Abstract

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

F. Shen, Y. Zhang, L. Yu, T. Fu, J. Wang, H. Wang, K. Cui, Microstructure and oxidation behavior of Nb-Si-based alloys for ultrahigh temperature applications: a comprehensive review. Coatings 11(11), 1373 (2021). https://doi.org/10.3390/coatings11111373

X. Zhang, T. Fu, K.K. Cui, Y.Y. Zhang, F.Q. Shen, J. Wang, L.H. Yu, H.B. Mao, A. Tolstoguzov, The protection, challenge, and prospect of anti-oxidation coating on the surface of niobium alloy. Coatings 11(7), 742 (2021). https://doi.org/10.3390/coatings11070742

J. Wang, Y. Zhang, L. Yu, K. Cui, T. Fu, H. Mao, Effective separation and recovery of valuable metals from waste Ni-based batteries: A comprehensive review. Chem. Eng. J. 439, 135767 (2022). https://doi.org/10.1016/j.cej.2022.135767

J.H. He, X.P. Guo, Y.Q. Qiao, Effect of Zr content on the structure and oxidation resistance of silicide coatings prepared by pack cementation technique. Corros. Sci. 147, 152–162 (2019). https://doi.org/10.3390/coatings12020141

D.Z. Yao, C.G. Zhou, J.Y. Yang, H.F. Chen, Experimental studies and modeling of the oxidation of multiphase niobium-base alloys. Corros. Sci. 51(11), 2617–2619 (2009). https://doi.org/10.1016/j.corsci.2009.06.053

Y.X. Li, J.H. Nie, Y.X. Yang, P.K. Bai, H.J. Zhang, Z.Y. Zhao, S.Z. Wei, J. Cai, Q.F. Guan, High-temperature oxidation behavior of nicocraly coatings deposited by laser cladding on 304 stainless steel. Met. Mater. Int. 28, 412–420 (2022). https://doi.org/10.1007/s12540-020-00927-y

L. Yu, F. Shen, T. Fu, Y. Zhang, K. Cui, J. Wang, X. Zhang, Microstructure and oxidation behavior of metal-modified Mo-Si-B alloys a review. Coatings 11(10), 1256 (2021). https://doi.org/10.3390/coatings11101256

L. Yu, Y. Zhang, T. Fu, J. Wang, K. Cui, F. Shen, Rare earth elements enhanced the oxidation resistance of Mo-Si-based alloys for high temperature application: a review. Coatings 11(9), 1144 (2021). https://doi.org/10.3390/coatings11091144

S. Zhang, X.P. Guo, Alloying effects on the microstructure and properties of Nb-Si based ultrahigh temperature alloys. Intermetallics 70, 33–44 (2016). https://doi.org/10.1016/j.intermet.2015.12.002

G. Kim, H. Shin, J. Lee, W. Lee, A review on silicide-based materials: thermoelectric and mechanical properties. Met. Mater. Int. 27, 2205–2219 (2021). https://doi.org/10.1007/s12540-020-00609-9

Y.C. Yan, H.S. Ding, Y.W. Kang, J.X. Song, Microstructure evolution and mechanical properties of Nb-Si based alloy processed by electromagnetic cold crucible directional solidification. Mater. Des. 55, 450–455 (2014). https://doi.org/10.1016/j.matdes.2013.10.017

Z.P. Sun, J.M. Guo, C. Zhang, X.P. Guo, X.D. Tian, Effect of Ti and Al interaction on microstructures and mechanical properties of the Nb-Ti-Si-Al alloys. Rare Metal Mater. Eng. 45(7), 1678–1682 (2016). https://doi.org/10.1016/S1875-5372(16)30139-4

I. Grammenos, P. Tsakiropoulos, Study of the role of Hf, Mo and W additions in the microstructure of Nb–20Si silicide based alloys. Intermetallics 19(10), 1612–1621 (2011). https://doi.org/10.1016/j.intermet.2011.06.008

S.S. Zhang, Y.C. Liu, T.W. Xu, M.X. Sun, Q. Zhang, Y. Wan, Effect of texture and microstructure on tensile behaviors in the polycrystalline pure niobium. Met. Mater. Int. 27, 4023–4034 (2021). https://doi.org/10.1007/s12540-020-00925-0

D.L. Pu, Y. Pan, Influence of high pressure on the structure, hardness and brittle-to-ductile transition of NbSi2 ceramics. Ceram. Int. 47(2), 2311–2318 (2021). https://doi.org/10.1016/j.ceramint.2020.09.073

G.M. Karthik, H.S. Kim, Heterogeneous aspects of additive manufactured metallic parts: a review. Met. Mater. Int. 27, 1–39 (2021). https://doi.org/10.1007/s12540-020-00931-2

Y. Pan, Structural Prediction and overall performances of CrSi2 disilicides: DFT investigations. ACS Sustain. Chem. Eng. 8, 11024–11030 (2020). https://doi.org/10.1021/acssuschemeng.0c04737

X. Fang, X.P. Guo, Y.Q. Qiao, Effect of Ti addition on microstructure and crystalline orientations of directionally solidified Nb–Si based alloys. Intermetallics 122, 106798 (2020). https://doi.org/10.1016/j.intermet.2020.106798

I. Grammenos, P. Tsakiropoulos, Study of the role of Al, Cr and Ti additions in the microstructure of Nb-18Si-5Hf base alloys. Intermetallics 18(2), 242–253 (2010). https://doi.org/10.1016/j.intermet.2009.07.020

Y.Y. Zhang, J.M. Qie, K.K. Cui, T. Fu, X.L. Fan, J. Wang, X. Zhang, Effect of hot dip silicon-plating temperature on microstructure characteristics of silicide coating on tungsten substrate. Ceram. Int. 46(4), 5223–5228 (2020). https://doi.org/10.1016/j.ceramint.2019.10.270

S. Zhang, X.P. Guo, Effects of Cr and Hf additions on the microstructure and properties of Nb silicide based ultrahigh temperature alloys. Mater. Sci. Eng. A 638, 121–131 (2015). https://doi.org/10.1016/j.msea.2015.04.003

Y.Y. Zhang, T. Fu, L.H. Yu, F.Q. Shen, J. Wang, K.K. Cui, Improving oxidation resistance of TZM alloy by deposited Si–MoSi2 composite coating with high silicon concentration, Ceram. Int. (2022). https://doi.org/10.1016/j.ceramint.2022.04.080

Y.Y. Zhang, S. Hussain, K.K. Cui, T. Fu, J. Wang, M.S. Javed, Y. Lv, B. Aslam, Microstructure and mechanical properties of MoSi2 coating deposited on Mo substrate by hot dipping processes. J. Nanoelectron. Optoelectron. 14(12), 1680–1685 (2019). https://doi.org/10.1166/jno.2019.2676

Y.Y. Zhang, Y.G. Li, C.G. Bai, Microstructure and oxidation behavior of Si-MoSi2 functionally graded coating on Mo substrate. Ceram. Int. 43(8), 6250–6256 (2017). https://doi.org/10.1016/j.ceramint.2017.02.024

F. Shen, L. Yu, T. Fu, Y. Zhang, H. Wang, K. Cui, J. Wang, S. Hussain, N. Akhtar, Effect of the Al, Cr and B elements on the mechanical properties and oxidation resistance of Nb-Si based alloys: a review. Appl. Phys. A 127, 852 (2021). https://doi.org/10.1007/s00339-021-05013-7

Y.Y. Zhang, T. Fu, K.K. Cui, F.Q. Shen, J. Wang, L.H. Yu, H.B. Mao, Evolution of surface morphology, roughness and texture of tungsten disilicide coatings on tungsten substrate. Vacuum 14, 110297 (2021). https://doi.org/10.1016/j.vacuum.2021.110297

K. Cui, H. Mao, Y. Zhang, J. Wang, H. Wang, T. Tan, T. Fu, Microstructure, mechanical properties, and reinforcement mechanism of carbide toughened ZrC-based ultra-high temperature ceramics. Compos. Interfaces (2022). https://doi.org/10.1080/09276440.2021.2012409

Y.Y. Zhang, K.K. Cui, Q.J. Gao, S. Hussain, Y. Lv, Investigation of morphology and texture properties of WSi2 coatings on W substrate based on contact-mode AFM and EBSD. Surf. Coat. Technol. 396(25), 125966 (2020). https://doi.org/10.1016/j.surfcoat.2020.125966

K. Zelenitsas, P. Tsakiropoulos, Effect of Al, Cr and Ta additions on the oxidation behaviour of Nb-Ti-Si in situ composites at 800 °C. Mater. Sci. Eng. A 416, 269–280 (2006). https://doi.org/10.1016/j.msea.2005.10.017

T. Fu, F.Q. Shen, Y.Y. Zhang, L.H. Yu, K.K. Cui, J. Wang, X. Zhang, Oxidation protection of high-temperature coatings on the surface of Mo-Based alloys-a review. Coatings 12(2), 141 (2022). https://doi.org/10.3390/coatings12020141

Y.Y. Zhang, L.H. Yu, T. Fu, J. Wang, F.Q. Shen, K.K. Cui, Microstructure evolution and growth mechanism of Si-MoSi2 composite coatings on TZM (Mo-0.5Ti-0.1Zr-0.02 C) alloy. J. Alloys Compd. 894(15), 162403 (2022). https://doi.org/10.1016/j.jallcom.2021.162403

Y.Y. Zhang, W.J. Ni, Y.G. Li, Effect of siliconizing temperature on microstructure and phase constitution of Mo–MoSi2 functionally graded materials. Ceram. Int. 44(10), 11166–11171 (2018). https://doi.org/10.1016/j.ceramint.2018.03.136

X. Tian, X. Guo, Z. Sun, Z. Yin, L. Wang, Formation of B-modified MoSi2 coating on pure Mo prepared through HAPC process. Int. J. Refract. Metals Hard Mater. 45, 8–14 (2014). https://doi.org/10.1016/j.ijrmhm.2014.03.003

B. Vishwanadh, R.H. Naina, S. Majumdar, R. Tewari, G.K.A. Dey, A study on the oxidation behavior of Nb alloy (Nb-1 pct Zr-0.1 pct C) and silicide-coated Nb alloys. Metall. Mater. Trans. A 44, 2258–2269 (2013). https://doi.org/10.1007/s11661-012-1554-1

L. Liu, H. Lei, J. Gong, C. Sun, Deposition and oxidation behaviour of molybdenum disilicide coating on Nb based alloys substrate by combined AIP/HAPC processes. Ceram. Int. 45(8), 10525–10529 (2019). https://doi.org/10.1016/j.ceramint.2019.02.115

J.C. Cheng, S. Yi, J.S. Park, Oxidation behavior of Nb-Si-B alloys with the NbSi2 coating layer formed by a pack cementation technique. Int. J. Refract Metal Hard Mater. 41, 103–109 (2013). https://doi.org/10.1016/j.ijrmhm.2013.02.010

S. Majumdar, J. Kishor, B. Paul, R.C. Hubli, J.K. Chakravartty, Isothermal oxidation behavior and growth kinetics of silicide coatings formed on Nb-1Zr-0.1C alloy. Corros. Sci. 95, 100–109 (2015). https://doi.org/10.1016/j.corsci.2015.02.035

E.H. Jordan, L. Xie, M. Gell, N.P. Padture, B. Cetegen, A. Ozturk, X. Ma, J. Roth, T.D. Xiao, P.E.C. Bryant, Superior thermal barrier coatings using solution precursor plasma spray. J. Therm. Spray Technol. 13, 57–65 (2004). https://doi.org/10.1007/s11666-004-0050-6

L. Sun, Q.G. Fu, X.Q. Fang, J. Sun, A MoSi2-based composite coating by supersonic atmospheric plasma spraying to protect Nb alloy against oxidation at 1500 °C. Surf. Coat. Technol. 325, 182–190 (2018). https://doi.org/10.1016/j.surfcoat.2018.07.091

D.L. Pu, Y. Pan, First-principles investigation of oxidation mechanism of Al-doped Mo5Si3 silicide. Ceram. Int. 48(8), 11518–11526 (2022). https://doi.org/10.1016/j.ceramint.2022.01.007

J. Yan, L. Liu, Z. Mao, H. Xu, Y. Wang, Effect of spraying powders size on the microstructure, bonding strength, and microhardness of MoSi2 coating prepared by air plasma spraying. J. Therm. Spray Technol. 23, 934–939 (2014). https://doi.org/10.1007/s11666-014-0120-3

Y.J. Choi, J.K. Yoon, G.H. Kim, W.Y. Yoon, J.M. Doh, K.T. Hong, High temperature isothermal oxidation behavior of NbSi2 coating at 1000–1450 °C. Corros. Sci. 129, 102–114 (2017). https://doi.org/10.1016/j.corsci.2017.10.002

J. Sun, T. Li, G.P. Zhang, Q.G. Fu, Different oxidation protection mechanisms of HAPC silicide coating on niobium alloy over a large temperature range. J. Alloy. Compd. 790, 1014–1022 (2019). https://doi.org/10.1016/j.jallcom.2019.03.229

Y.Y. Zhang, K.K. Cui, T. Fu, J. Wang, F.Q. Shen, X. Zhang, L.H. Yu, Formation of MoSi2 and Si/MoSi2 coatings on TZM (Mo-0.5Ti-0.1Zr-0.02C) alloy by hot dip silicon-plating method. Ceram. Int. 47(16), 23053–23065 (2021). https://doi.org/10.1016/j.ceramint.2021.05.020

L. Liu, H.Q. Zhang, H. Lei, H.Q. Li, J. Gong, C. Sun, Influence of different coating structures on the oxidation resistance of MoSi2 coatings. Ceram. Int. 46(5), 5993–5997 (2020). https://doi.org/10.1016/j.ceramint.2019.11.055

L. Sun, Q.G. Fu, J. Sun, G.P. Zhang, Comparison investigation of hot corrosion exposed to Na2SO4 salt and oxidation of MoSi2-based coating on Nb alloy at 1000 °C. Surf. Coat. Technol. 385, 125388 (2020). https://doi.org/10.1016/j.surfcoat.2020.125388

Y.L. Guo, L.N. Jia, B. Kong, F.X. Zhang, J.H. Liu, H. Zhang, Improvement in the oxidation resistance of Nb-Si based alloy by selective laser melting. Corros. Sci. 127, 260–269 (2017). https://doi.org/10.1016/j.corsci.2017.08.022

S. Majumdar, J. Kishor, B. Paul, R.C. Hubli, J.K. Chakravartty, Isothermal oxidation behavior and growth kinetics of silicide coatings formed on Nb-1Zr-0.1C alloy. Corros. Sci. 95, 100–109 (2015). https://doi.org/10.1016/j.corsci.2015.02.035

Y. Pan, W.M. Guan, The hydrogenation mechanism of PtAl and IrAl thermal barrier coatings from first-principles investigations. Int. J. Hydrog. Energy 45(38), 20032–20041 (2020). https://doi.org/10.1016/j.ijhydene.2020.04.290

G. Yue, X.P. Guo, Y.Q. Qiao, Microstructure and oxidation behaviors at 800°C and 1250°C of MoSi2/ReSi2/NbSi2 compound coating prepared by electrodeposition and then pack cementation. Ceram. Int. 45(9), 11739–11748 (2019). https://doi.org/10.1016/j.ceramint.2019.03.050

A. Allam, P. Boulet, M.C. Record, Linear thermal expansion coefficients of higher manganese silicide compounds. Phys. Proc. 55, 24–29 (2014). https://doi.org/10.1016/j.phpro.2014.07.004

G.P. Zhang, J. Sun, Q.G. Fu, Effect of mullite on the microstructure and oxidation behavior of thermal sprayed MoSi2 coating at 1500 °C. Ceram. Int. 46(8), 10058–10066 (2020). https://doi.org/10.1016/j.ceramint.2019.12.273

G.P. Zhang, J. Sun, Q.G. Fu, Microstructure and oxidation behavior of plasma sprayed WSi2-mullite MoSi2 coating on niobium alloy at 1500 °C. Surf. Coat. Technol. 400, 126210 (2020). https://doi.org/10.1016/j.surfcoat.2020.126210

M.Z. Alam, A.S. Rao, D.K. Das, Microstructure and high temperature oxidation performance of silicide coating on Nb-based alloy C-103. Oxid. Met. 73, 513–530 (2010). https://doi.org/10.1007/s11085-010-9190-x

G. Yue, X.P. Guo, Y.Q. Qiao, C.G. Zhou, Electrodeposition of Mo/Re duplex layer and preparation of MoSi2/ReSi2/NbSi2 compound coating on Nb-Ti-Si based alloy. Corros. Sci. 153, 283–291 (2019). https://doi.org/10.1016/j.corsci.2019.03.053

Y.Y. Zhang, J. Zhao, J.H. Li, J. Lei, X.K. Cheng, Effect of hot-dip siliconizing time on phase composition and microstructure of Mo-MoSi2 high temperature structural materials. Ceram. Int. 45(5), 5588–5593 (2019). https://doi.org/10.1016/j.ceramint.2018.12.018

M.T. Wang, Q.S. Zheng, A.Y. Chen, Y. Li, X.W. Zhang, D.L. Zhang, S. Jin, D.H. Xiong, W. Deng, Crystallization, thermal expansion and hardness of Y2O3–Al2O3–SiO2 glasses. Ceram. Int. 47(17), 25059–25066 (2021). https://doi.org/10.1016/j.ceramint.2021.05.236

A. Anagnostopoulos, A. Alexiadis, Y.L. Ding, Simplified force field for molecular dynamics simulations of amorphous SiO2 for solar applications. Int. J. Therm. Sci. 160, 106647 (2021). https://doi.org/10.1016/j.ijthermalsci.2020.106647

Y.Y. Zhang, K.K. Cui, T. Fu, J. Wang, J.M. Qie, X. Zhang, Synthesis WSi2 coating on W substrate by HDS method with various deposition times. Appl. Surf. Sci. 511, 145551 (2020). https://doi.org/10.1016/j.apsusc.2020.145551

W. Wang, B.F. Yuan, C.G. Zhou, Formation and oxidation resistance of germanium modified silicide coating on Nb based in situ composites. Corros. Sci. 80, 164–168 (2014). https://doi.org/10.1016/j.corsci.2013.11.029

B. Voglewede, V.R. Rangel, S.K. Varma, The effects of uncommon silicides on the oxidation behavior of alloys from the Nb–Cr–Si system. Corros. Sci. 61, 123–133 (2012). https://doi.org/10.1016/j.corsci.2012.04.029

T. Fu, K.K. Cui, Y.Y. Zhang, J. Wang, X. Zhang, F.Q. Shen, L.H. Yu, H.B. Mao, Microstructure and oxidation behavior of anti-oxidation coatings on Mo-Based alloys through HAPC Process: a review. Coatings 11(8), 883 (2021). https://doi.org/10.3390/coatings11080883

M. Fukumoto, Y. Matsumura, S. Hayashi, T. Narita, K. Sakamoto, A. Kasama, R. Tanaka, Coatings of Nb-based alloy by Cr and/or Al pack cementations and its oxidation behavior in Air at 1273–1473 K. Mater. Trans. 44(4), 731–735 (2003). https://doi.org/10.2320/matertrans.44.731

Y.Q. Qiao, M.Y. Li, X.P. Guo, Development of silicide coatings over Nb–NbCr2 alloy and their oxidation behavior at 1250 °C. Surf. Coat. Technol. 285, 921–930 (2014). https://doi.org/10.1016/j.surfcoat.2014.07.058

Y. Liu, W. Shao, C.L. Wang, C.G. Zhou, Microstructure and oxidation behavior of Mo-Si-Al coating on Nb-based alloy. J. Alloy. Compd. 735, 2247–2255 (2018). https://doi.org/10.1016/j.jallcom.2017.11.339

L.F. Su, O.L. Steffes, H. Zhang, J.H. Perepezko, An ultra-high temperature Mo-Si-B based coating for oxidation protection of NbSS/Nb5Si3 composites. Appl. Surf. Sci. 337, 38–44 (2015). https://doi.org/10.1016/j.apsusc.2015.02.061

R. Sakidja, J.S. Park, J. Hamann, J.H. Perepezko, Synthesis of oxidation resistant silicide coating on Mo-Si-B alloys. Scripta Mater. 53(6), 723–728 (2005). https://doi.org/10.1016/j.scriptamat.2005.05.015

T. Tabaru, K. Shobu, H. Hirai, S. Hanada, Influences of Al content and secondary phase of Mo5(Si, Al)3 on the oxidation resistance of Al-rich Mo(Si, Al)2-base composites. Intermetallics 11(7), 721–733 (2003). https://doi.org/10.1016/S0966-9795(03)00072-4

M.Z. Alam, B. Venkataraman, B. Sarma, D.K. Das, MoSi2 coating on Mo substrate for short-term oxidation protection in air. J. Alloy. Compd. 487(1), 335–340 (2009). https://doi.org/10.1016/j.jallcom.2009.07.141

J.Y. Wu, W. Wang, C.G. Zhou, Microstructure and oxidation resistance of Mo–Si–B coating on Nb based in situ composites. Corros. Sci. 87, 421–426 (2014). https://doi.org/10.1016/j.corsci.2014.07.006

P. Ritt, R. Sakidja, J.H. Perepezko, Mo–Si–B based coating for oxidation protection of SiC-C composites. Surf. Coat. Technol. 206(19–20), 4166–4172 (2012). https://doi.org/10.1016/j.surfcoat.2012.04.016

T. Feng, H.J. Li, X.H. Shi, X. Yang, Y.X. Li, X.Y. Yao, Sealing role of B2O3 in MoSi2–CrSi2–Si/B-modified SiC coating for C/C composites. Corros. Sci. 60, 4–9 (2012). https://doi.org/10.1016/j.corsci.2012.04.018

C. Wang, W. Shao, W. Wang, C. Zhou, Oxidation behaviour of a Ge-modified silicide coating on an Nb-Si based alloy in the moderate temperature range. Corros. Sci. 163, 108249 (2020). https://doi.org/10.1016/j.corsci.2019.108249

L.R. Xiao, X.J. Zhou, Y.F. Wang, R. Pu, G. Zhao, Z.Q. Shen, Y.L. Huang, S.N. Liu, Z.Y. Cai, X.J. Zhao, Formation and oxidation behavior of Ce-modified MoSi2-NbSi2 coating on niobium alloy. Corros. Sci. 173, 108751 (2020). https://doi.org/10.1016/j.corsci.2020.108751

Z. Cai, D. Zhang, X. Chen, Y. Huang, Y. Peng, C. Xu, S. Huang, R. Pu, S. Liu, X. Zhao, L. Xiao, A novel ultra-high-temperature oxidation protective MoSi2-TaSi2 ceramic coating for tantalum substrate. J. Eur. Ceram. Soc. 39(7), 2277–2286 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.02.037

V. Sreedhar, J. Das, R. Mitra, S.K. Roy, Influence of superficial CeO2 coating on high temperature oxidation behavior of Ti–6Al–4V. J. Alloy. Compd. 519, 106–111 (2012). https://doi.org/10.1016/j.jallcom.2011.12.118

W. Wang, C.G. Zhou, Characterization of microstructure and oxidation resistance of Y and Ge modified silicide coating on Nb-Si based alloy. Corros. Sci. 110, 114–122 (2016). https://doi.org/10.1016/j.corsci.2016.04.026

S. Majumdar, P. Sengupta, G.B. Kale, I.G. Sharma, Development of multilayer oxidation resistant coatings on niobium and tantalum. Surf. Coat. Technol. 200(12–13), 3713–3718 (2006). https://doi.org/10.1016/j.surfcoat.2005.01.034

B. Zhang, W. Song, L. Wei, Y. Xiu, H. Xu, D.B. Dingwell, H. Guo, Novel thermal barrier coatings repel and resist molten silicate deposits. Scripta Mater. 163, 71–76 (2019). https://doi.org/10.1016/j.scriptamat.2018.12.028

Q.Y. Hou, W. Shao, M.F. Li, C.G. Zhou, Interdiffusion behavior of Mo-Si-B/Al2O3 composite coating on Nb-Si based alloy. Surf. Coat. Technol. 401, 126243 (2020). https://doi.org/10.1016/j.surfcoat.2020.126243

C.L. Yeh, Y.H. Wang, Formation of zirconium silicide–Al2O3 composites from PTFE-assisted ZrO2/Si/Al combustion synthesis. Vacuum 184, 109877 (2021). https://doi.org/10.1016/j.vacuum.2020.109877

K.K. Cui, T. Fu, Y.Y. Zhang, J. Wang, H.B. Mao, T.B. Tan, Microstructure and mechanical properties of CaAl12O19 reinforced Al2O3-Cr2O3 composites. J. Eur. Ceram. Soc. 41(15), 7935–7945 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.08.024

Y.Q. Qiao, J.P. Kong, Q. Li, X.P. Guo, Comparison of two kinds of Si–B–Y co-deposition coatings on an Nb-Ti-Si based alloy by pack cementation method. Surf. Coat. Technol. 327, 93–100 (2017). https://doi.org/10.1016/j.surfcoat.2017.07.013

T. Fu, K.K. Cui, Y.Y. Zhang, J. Wang, F.Q. Shen, L.H. Yu, J.M. Qie, X. Zhang, Oxidation protection of tungsten alloys for nuclear fusion applications: a comprehensive review. J. Alloy. Compd. 884, 161057 (2021). https://doi.org/10.1016/j.jallcom.2021.161057

Y. Zhang, L. Yu, T. Fu, J. Wang, F. Shen, K. Cui, H, Wang, Microstructure and oxidation resistance of Si-MoSi2 ceramic coating on TZM (Mo-0.5 Ti-0.1 Zr-0.02 C) alloy at 1500° C. Surf. Coat. Technol. 431, 128037 (2022). https://doi.org/10.1016/j.surfcoat.2021.128037

K. Cui, Y. Zhang, T. Fu, J. Wang, X. Zhang, Toughening mechanism of mullite matrix composites: a review. Coatings 10(7), 672 (2020). https://doi.org/10.3390/coatings10070672

M. Sankar, V.S. Prasad, R.G. Baligidad, M.Z. Alam, D.K. Das, A.A. Gokhale, Microstructure, oxidation resistance and tensile properties of silicide coated Nb-alloy C-103. Mater. Sci. Eng. A 645, 339–346 (2015). https://doi.org/10.1016/j.msea.2015.07.063

Funding

This work was supported by the Anhui Province Science Foundation for Excellent Young Scholars (2108085Y19) and the National Natural Science Foundation of China (No. 51604049).

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. YYZ: Conceptualization, Investigation, and Supervision. YYZ and TF: Writing original draft and image processing. TF, KKC, and JW: Validation, Resources, Investigation, Writing—review and editing. XZ, KCZ, LHY and FQS: Visualization, Writing—review and editing. All authors have given approval to the final version of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Fu, T., Yu, L. et al. Anti-Corrosion Coatings for Protecting Nb-Based Alloys Exposed to Oxidation Environments: A Review. Met. Mater. Int. 29, 1–17 (2023). https://doi.org/10.1007/s12540-022-01222-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01222-8