Abstract

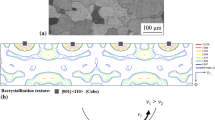

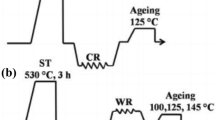

The influence of the asymmetric rolling process (ASR) and thickness reduction on the microstructure and mechanical properties of Al–Mg–Si alloys is studied. The specimens of the ASR and higher thickness reduction show higher strength (both the ultimate tensile strength and yield strength) and lower elongation (El). However, both the strength and El are reduced with the increase of the rotation speed ratio (ω1/ω2) in the specimens treated by the ASR. The grain size, density of dislocations, volume fraction of deformation texture and number density of precipitates are the main reasons causing the difference in strength and El. The increment in strength is mainly due to the increase of deformation texture, density of dislocations during the cold rolling and number density of precipitates formed during subsequent ageing. The reduction of volume fraction of deformation texture and number density of precipitates are responsible for the decrease of the strength in the specimens treated by the ASR. The high-density dislocations in turn provide little room for the accumulation of dislocations and therefore reduces the EI.

Graphic Abstract

Similar content being viewed by others

References

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, A. Vieregge, Mater. Sci. Eng. A 280, 37 (2000)

M.A.V. Huis, J.H. Chen, M.H.F. Sluiter, H.W. Zandbergena, Acta Mater. 55, 2183 (2007)

Y. Birol, M. Karlk, Mater. Sci. Technol. 21, 153 (2005)

S. Karabay, Mater. Des. 27, 821 (2006)

W.C. Yang, L.P. Huang, R.R. Zhang, M.P. Wang, Z. Li, Y.L. Jia, R.S. Lei, X.F. Sheng, J. Alloy. Compd. 514, 220 (2012)

A.K. Gupta, D.J. Lloyd, S.A. Court, Mater. Sci. Eng. A 316, 11 (2001)

X.X. Xu, Z. Yang, Y.L. Ye, G.X. Wang, X.L. He, Mater. Charact. 119, 114 (2016)

K. Buchanan, K. Colas, J. Ribis, A. Lopez, J. Garnier, Acta Mater. 132, 209 (2017)

J.Z. Dang, Y.F. Huang, J. Cheng, T. Nonferr. Metal. Soc. 19, 540 (2009)

J. Man, L. Jing, S.G. Jie, J. Alloy. Compd. 437, 146 (2007)

L.Z. Yan, Y.A. Zhang, X.W. Li, Z.H. Li, F. Wang, H.W. Liu, B.Q. Xiong, Prog. Nat. Sci. Mater. 24, 97 (2014)

M.Y. Song, I.S. Kim, J.H. Kim, S.K. Hong, Met. Mater. Int. 27, 1374 (2021)

H. Li, M. Qingzhong, Z. Wang, F. Miao, B. Fang, R. Song, Z.Q. Zheng, Mater. Sci. Eng. A 617, 165 (2014)

L. Mei, X.P. Chen, G.J. Huang, Q. Liu, J. Alloy. Compd. 777, 259 (2019)

H. Li, Z.H. Yan, L.Y. Cao, Mater. Sci. Eng. A 728, 88 (2018)

Y. Aruga, M. Kozuka, Y. Takaki, T. Sato, Scripta Mater. 116, 82 (2016)

Y.Y. Weng, Z.H. Jia, L.P. Ding, M.P. Liu, X.Z. Wu, Q. Liu, Prog. Nat. Sci. Mater. 28, 363 (2018)

D.Y. Yin, Q. Xiao, Y.Q. Chen, H.Q. Liu, D.Q. Yi, B. Wang, S.P. Pan, Mater. Des. 95, 329 (2016)

L.P. Ding, Z.H. Jia, Y.Y. Liu, Y.Y. Weng, Q. Liu, J. Alloy. Compd. 688, 362 (2016)

J. Buha, R.N. Lumley, A.G. Crosky, Metall. Mater. Trans. A 37, 3119 (2006)

R.N. Lumley, I.J. Polmear, A.J. Morton, Mater. Sci. Forum. 396–402, 893 (2002)

X.H. Xu, Y.L. Deng, S.Q. Chi, X.B. Guo, J. Mater. Res. Technol. 9, 230 (2020)

Y.K. Xie, Y.L. Deng, Y. Wang, X.B. Guo, J. Alloy. Compd. 836, 155445 (2020)

C.Q. Ma, L.G. Hou, J.S. Zhang, L.Z. Zhuang, Mater. Sci. Eng. A 733, 307 (2018)

S. Wronski, B. Bacroix, Acta Mater. 76, 404 (2014)

M.Y. Amegadzie, D.P. Bishop, Mater. Today Commun. 25, 101283 (2020)

J. Sidor, A. Miroux, R. Petrov, L. Kestens, Acta Mater. 56, 2495 (2008)

H. Yu, C. Lu, K. Tieu, X. Liu, Y. Sun, Q. Yu, C. Kong, Sci. Rep. 2, 772 (2012)

D.C.C. Magalhes, A.M. Kliauga, M. Ferrante, V.L. Sordi, Mater. Sci. Eng. A 736, 53 (2018)

Z. Zribi, H.H. Ktari, F. Herbst, V. Optasanu, N. Njah, Mater. Charact. 153, 190 (2019)

P.J. Konijnenberg, S. Zaefferer, D. Raabe, Acta Mater. 99, 402 (2015)

H. Jin, D.J. Lloyd, Mater. Sci. Technol. 26, 754 (2010)

Li. Ding, Z. Jia, J.-F. Nie, Y. Weng, L. Cao, H. Chen, X. Wu, Q. Liu, Acta Mater. 145, 437 (2018)

W.C. Yang, M.P. Wang, R.R. Zhang, Q. Zhang, X.F. Sheng, Scripta Mater. 62, 705 (2010)

W.J. He, X. Chen, N. Liu, B.F. Luan, G.H. Yuan, Q. Liu, J. Alloy. Compd. 699, 160 (2017)

M. Abbasi-Baharanchi, F. Karimzadeh, M.H. Enayati, Mater. Sci. Eng. A 683, 56 (2017)

Acknowledgements

This work was supported by the National Key R&D Program of China (Project No. 2016YFB0300901), and the National Science Foundation of China (Project No. 51705539). The authors would like to take this opportunity to express their appreciation.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Xu Xuehong, Deng Yunlai, Guo Xiaobin and Pan Qinglin. The first draft of the manuscript was written by Xu Xuehong and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, X., Deng, Y., Guo, X. et al. Influence of Asymmetric Rolling Process and Thickness Reduction on the Microstructure and Mechanical Properties of the Al–Mg-Si Alloy. Met. Mater. Int. 28, 1620–1629 (2022). https://doi.org/10.1007/s12540-021-01050-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01050-2